GMAW welding method of low-alloy super-strength steel Q1100E thin sheet

A technology of ultra-high-strength steel and welding methods, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of low tensile strength of butt joints and untested cold bending performance, so as to facilitate industrial application and realize light weight The effect of quantification and process operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

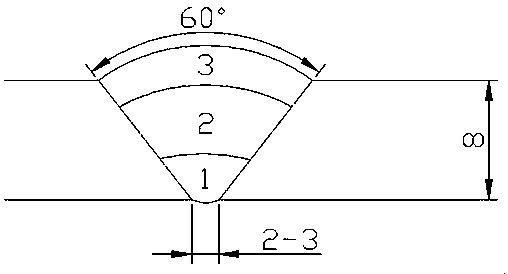

[0029] Embodiment 1, comparative example 1-1, and the welding test plate of comparative example 1-2 select the same base metal, and the thickness of the steel plate is 8mm; the components and weight percentages of the steel are: C=0.16, Si=0.18, Mn=1.13, P=0.008, S=0.0013, Al=0.036, Nb=0.015, V=0.05, Ti=0.016, Cr=0.21, Mo=0.55, Ni=0.30, B=0.0019, CEV=0.53, the balance is Fe and not Avoid impurities; its yield strength is 1176MPa, tensile strength is 1346MPa, elongation is 16%, and impact energy at -40°C is 70J / 67J / 69J (sample size is 5mm×10mm×55mm).

Embodiment 2

[0030] The welding test plate of embodiment 2 is taken from the Q1100E steel plate of 10mm thickness, and the composition and weight percent of steel are: C=0.18, Si=0.26, Mn=0.95, P=0.011, S=0.0025, Al=0.042, Nb= 0.016, V=0.037, Ti=0.010, Cr=0.28, Mo=0.57, Ni=0.02, B=0.0018, CEV=0.52, the balance is Fe and unavoidable impurities; its yield strength is 1200MPa, and its tensile strength is 1390MPa, the elongation rate is 17%, and the impact energy at -40°C is 72J / 60J / 58J (the sample size is 7.5mm×10mm×55mm).

Embodiment 3

[0031]The welding test plate of embodiment 3 is taken from the Q1100E steel plate of 12mm thickness, and the composition and weight percent of steel are: C=0.19, Si=0.25, Mn=0.85, P=0.009, S=0.002, Al=0.025, Nb= 0.012, V=0.056, Ti=0.012, Cr=0.20, Mo=0.75, Ni=0.40, B=0.0022, CEV=0.56, the balance is Fe and unavoidable impurities; its yield strength is 1149MPa, and its tensile strength is 1374MPa, the elongation is 15.5%, and the impact energy at -40°C is 72J / 64J / 69J (the sample size is 10mm×10mm×55mm).

[0032] The 980MPa high-strength steel welding wire used in the embodiment is T Union GM-120, which is purchased from the market. The diameter of the welding wire is 1.2mm; the mechanical properties of the deposited metal are: tensile strength ≥ 980MPa, yield strength ≥ 890MPa, elongation ≥ 15%, impact energy at -40°C ≥ 47J; the main chemical composition and weight percentage are: C= 0.10, Si=0.80, Mn=1.80, Cr=0.35, Mo=0.60, Ni=2.25, P=0.014, S=0.013, the balance is Fe and unav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com