High-strength stainless steel for deep sea cryogenic engineering and manufacturing method of steel

A low-temperature engineering and manufacturing method technology, applied in the field of stainless steel, can solve the problems that restrict the development and utilization of resources, achieve the effect of excellent low-temperature toughness and corrosion resistance, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

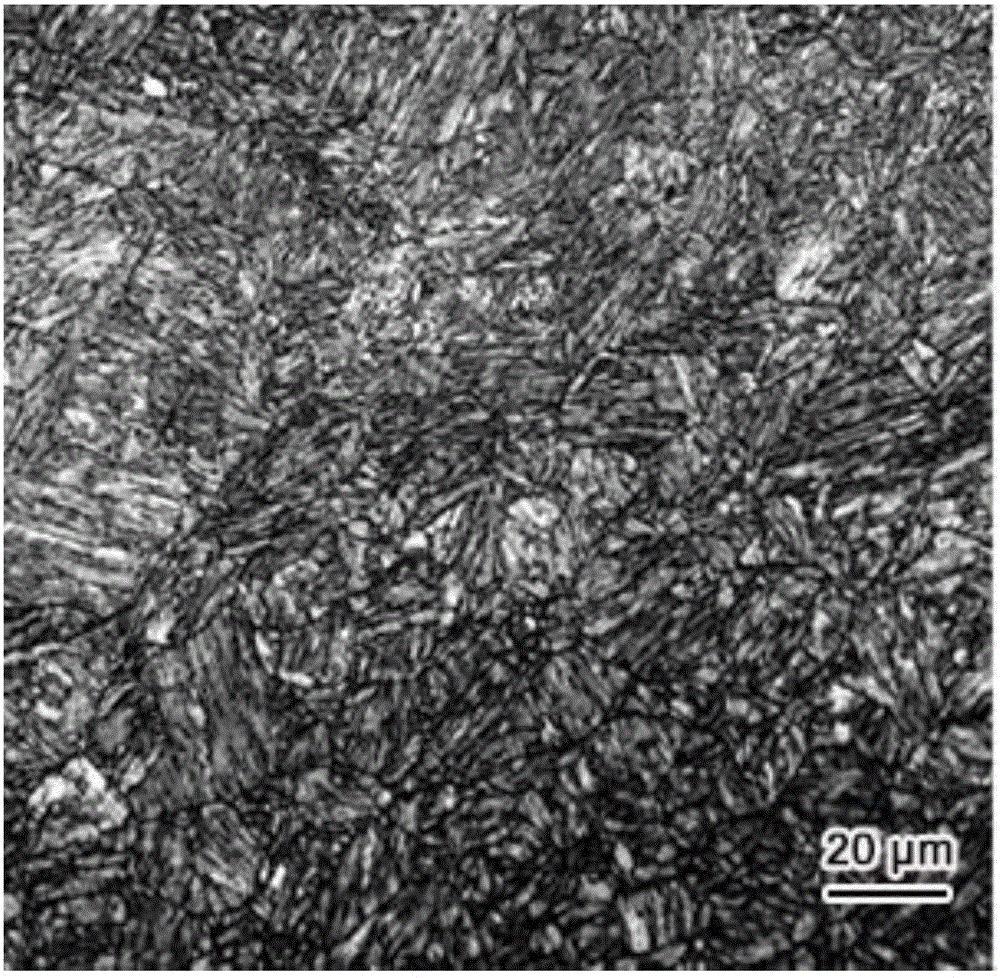

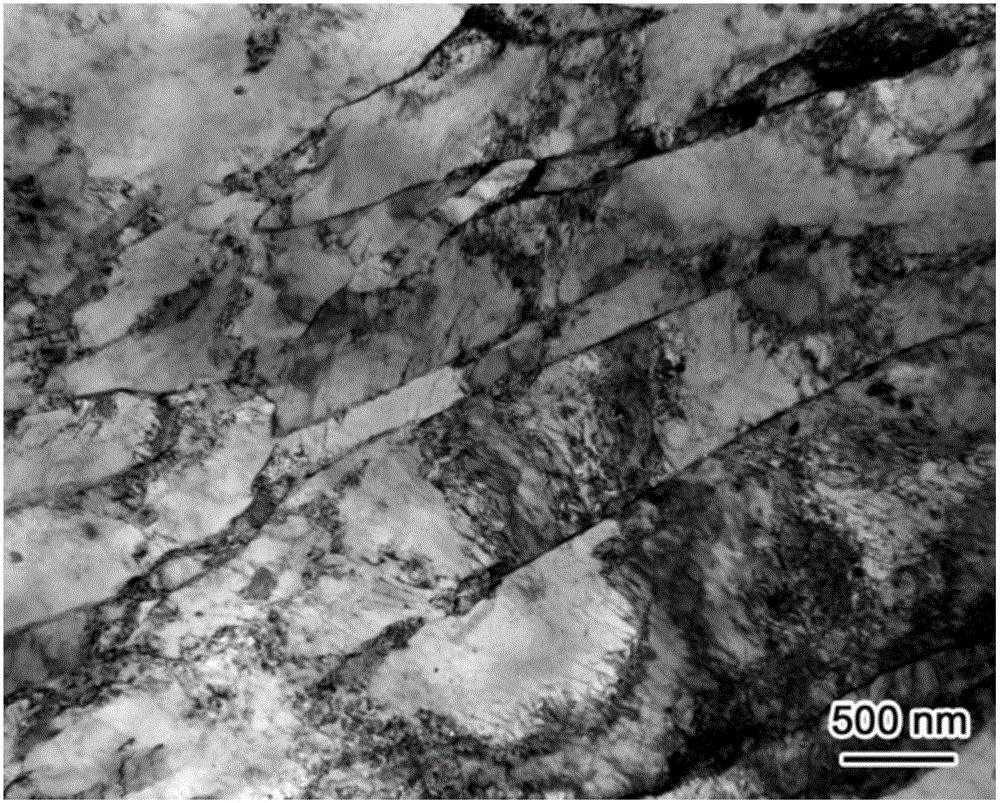

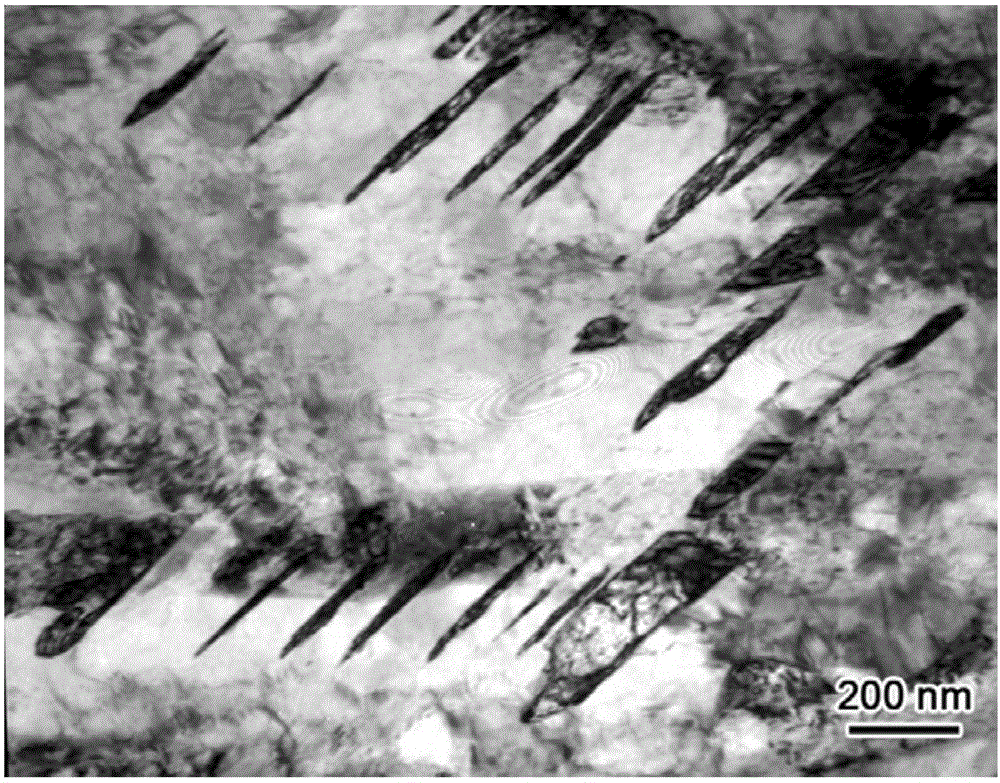

Image

Examples

Embodiment Construction

[0030] The embodiment of the present invention is three furnaces of prototype steel with different aluminum contents, and its chemical composition is shown in Table 1. The examples all adopt vacuum induction furnace+vacuum consumable furnace duplex smelting process, after smelting, steel ingots are annealed, billeted and then rolled into Φ30 rods. Table 2 shows the mechanical and salt spray corrosion resistance properties of three examples after heat treatment at 925°C / 1h oil cooling +0°C / 1h air cooling+450-520°C / 4h air cooling. It can be seen that with the gradual increase of the aluminum content in the composition of the examples, under the same heat treatment system, the tensile strength and yield strength of the steel gradually increase, but the salt spray corrosion resistance gradually decreases. Therefore, considering comprehensively, while meeting the requirements of the strength level, the aluminum content in the steel should be reduced as much as possible in order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com