Gas liquefaction and separation device

A liquid phase separation, gas technology, applied in lighting and heating equipment, liquefaction, separation methods, etc., can solve problems such as pressure loss and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

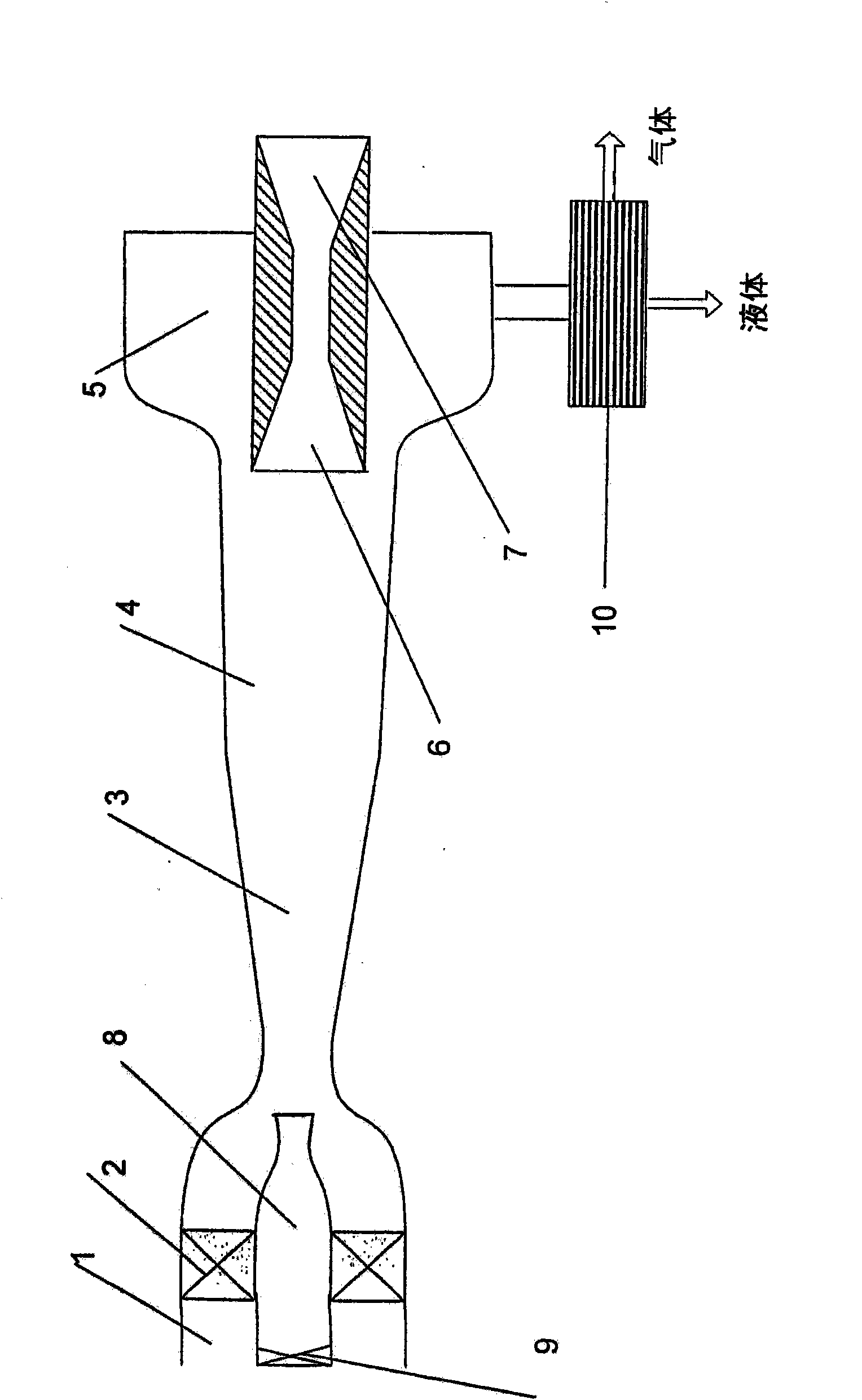

[0052] One embodiment of a gas liquefaction and separation plant, as shown in figure 1 , including the following components coaxially installed in sequence: a premix chamber 1 with a gas flow swirling device 2; an ultrasonic nozzle 3 with a working section 4 attached thereto; a liquid phase separation device 5 attached to the working paragraph. An ultrasonic diffuser 6 and an infrasonic diffuser 7 are arranged downstream of the working section 4 at the outlet of the nozzle 3 . An additional ultrasonic nozzle 8 is placed in the premix chamber 1 of the device, the inlet of which nozzle is provided with means 9 for regulating the gas flow rate in the additional nozzle. The inlet of the additional nozzle is located upstream of the gas flow swirler 2 and the outlet is located in the infrasonic part of the main nozzle. This structural configuration is in principle used for strong initial convolutions. The liquid phase separation device 5 is connected with a gas-liquid separator 1...

Embodiment 2

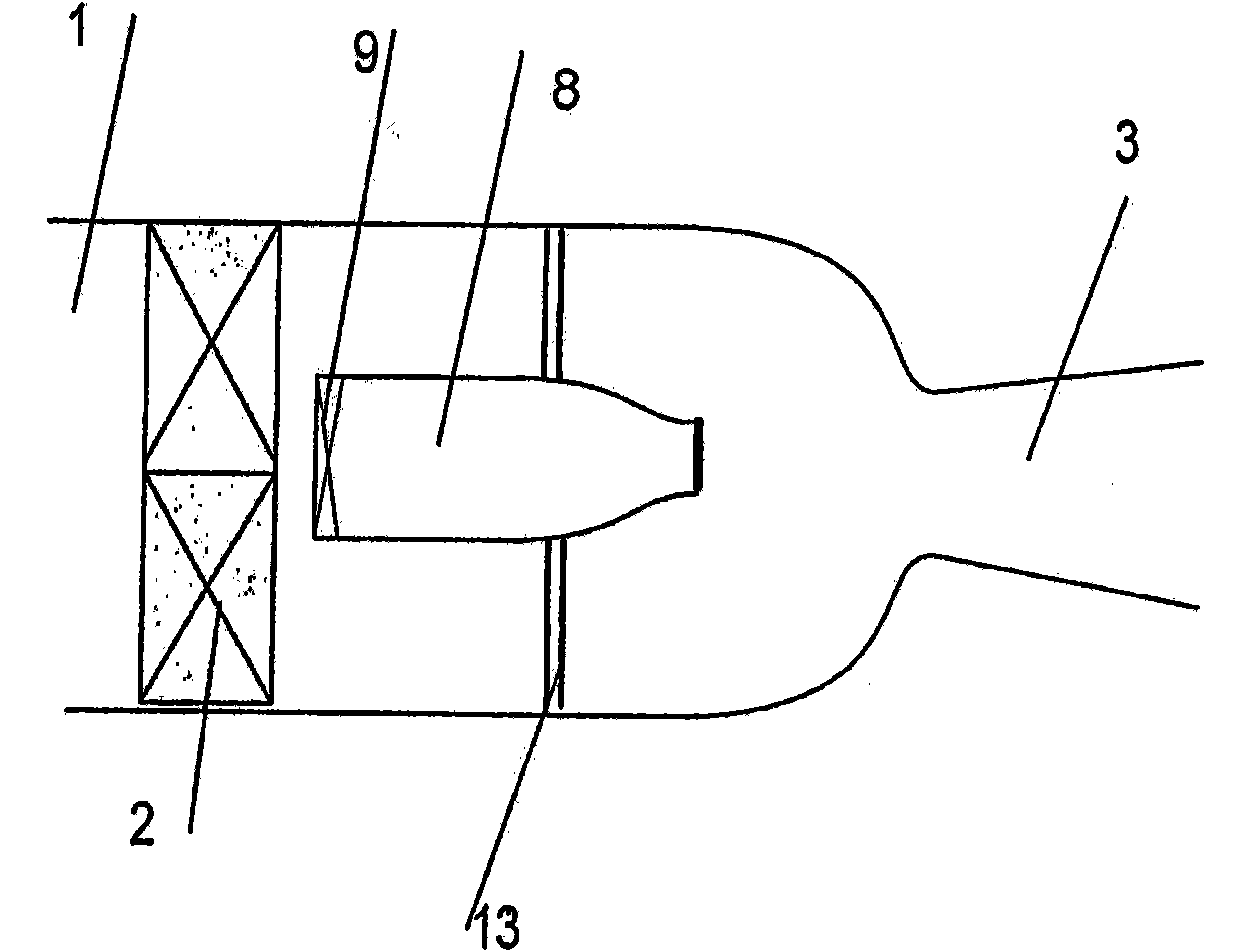

[0066] Another embodiment of the gas liquefaction and separation apparatus, as shown in figure 2 (Only a cross-sectional view of the premix chamber is shown, other elements similar to figure 1 ), including the following components coaxially installed in sequence: a premix chamber 1 with a gas flow swirling device 2; an ultrasonic nozzle 3 with a working section 4 attached thereto; a liquid phase separation device 5 with an attached attached to the working section. An ultrasonic diffuser 6 and an infrasonic diffuser 7 are arranged downstream of the working section 4 at the outlet of the nozzle 3 . An additional ultrasonic nozzle 8 is placed in the premix chamber 1 of the device by means of a rod 13, the inlet of the nozzle being provided with means 9 for regulating the gas flow rate in the additional nozzle. The additional nozzle inlet is located downstream of the gas flow swirler 2 . This structural configuration is in principle used for relatively weak initial maneuvers. ...

Embodiment 3

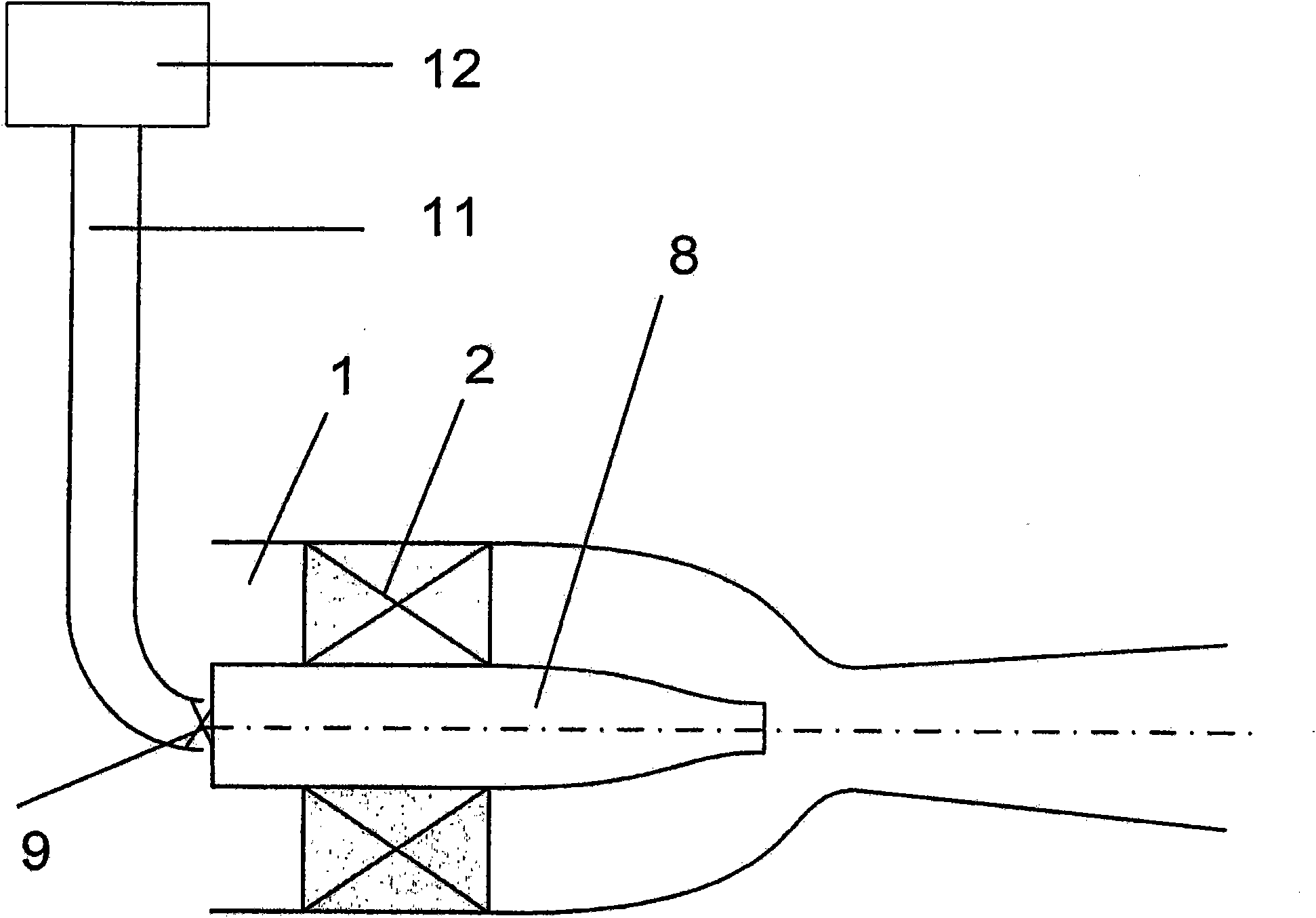

[0074] Yet another embodiment of the gas liquefaction and separation apparatus, as shown in image 3 (Only a cross-sectional view of the premix chamber and external gas source is shown, other components similar to figure 1 ), including the following components coaxially installed in sequence: a premix chamber 1 with a gas flow swirling device 2; an ultrasonic nozzle 3 with a working section 4 attached thereto; a liquid phase separation device 5 with an attached attached to the working section. An ultrasonic diffuser 6 and an infrasonic diffuser 7 are arranged downstream of the working section 4 at the outlet of the nozzle 3 . An additional infrasonic nozzle 8 is placed in the premix chamber 1 of the device, the inlet of which is provided with means 9 for regulating the gas flow rate in the additional nozzle. The additional nozzle inlet is connected via line 11 to an external gas source 12, which may be any known source. For example, it may be an outlet of any appliance for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com