Separation type gas-control high-temperature pulse valve

A pulse valve, separation technology, applied in separation methods, dispersed particle separation, valve lift and other directions, can solve the problems of short fatigue life, high cost, affecting the surrounding environment, etc., to improve temperature resistance, low manufacturing cost, improve The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

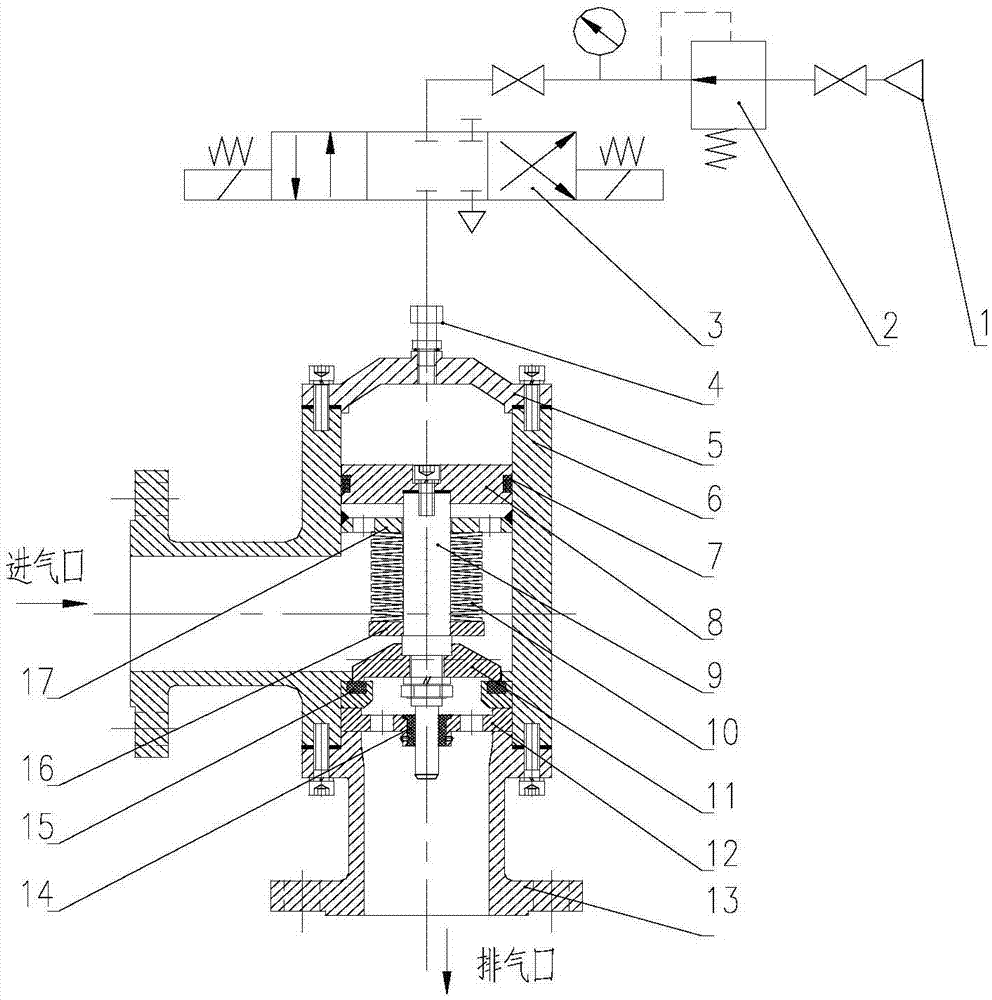

[0029] like figure 1 As shown, a separate air-controlled high-temperature pulse valve includes two separate parts. The first part is an electromagnetic reversing valve connected to the gas source, and the second part is the pulse valve body. The two parts are connected by a gas pipeline. The separate structure can weaken the impact of the high temperature pulse valve body on the solenoid valve, and the two can be installed separately at a certain distance.

[0030] The pulse valve body mainly includes end cover 5, valve body 6, seal 7, piston 8, piston rod 9, disc spring group 10, gland 11, support 12, exhaust flange 13, graphite bearing 14, seal Ring 15, baffle plate 16 and support plate 17.

[0031] The piston 8, the piston rod 9, the disc spring group 10, the gland 11 and the like form a piston assembly, and the entire piston assembly can m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com