Dual-pulse quick nitriding method and device based on induction heating

An induction heating, double-pulse technology, applied in the field of metal rapid nitriding surface strengthening, to achieve the effect of easy automatic control, high speed and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

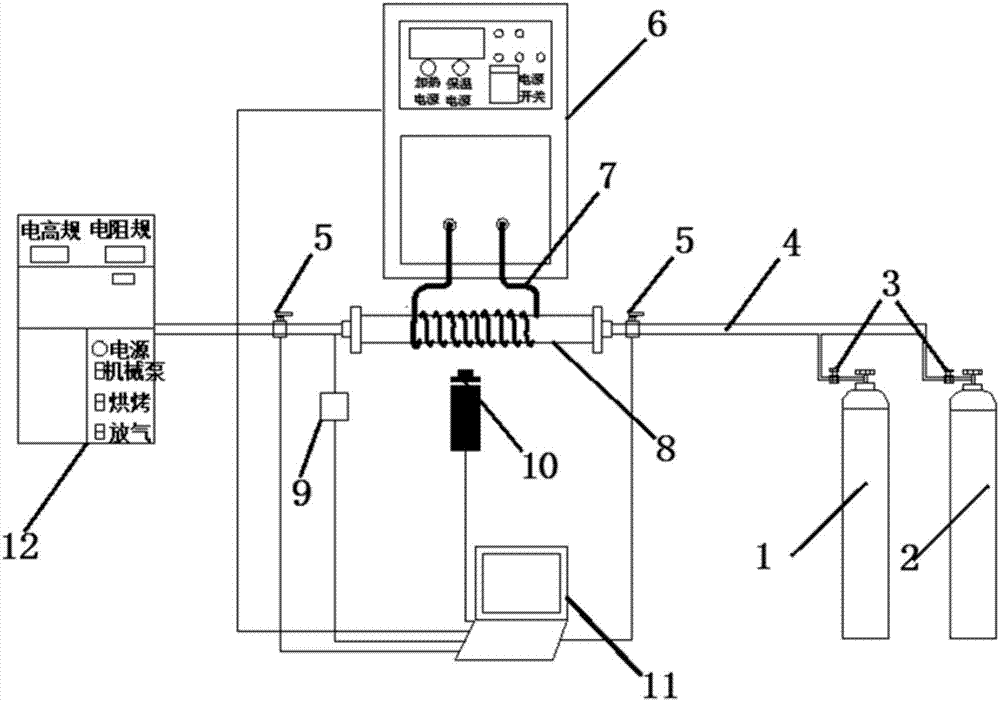

Method used

Image

Examples

Embodiment 1

[0032] Carry out pre-treatment of 38CrMoAl nitriding steel samples (sample arrangement, cleaning and activation, etc.), put the pretreated samples into a quartz vacuum tube, seal the quartz vacuum tube, check for leaks, and introduce high-purity argon The air is driven to remove the air in the vacuum tube, and then the vacuum tube is evacuated. When the vacuum requirement is met, the high-frequency machine is turned on to heat the sample in the vacuum tube, and the set temperature fluctuates between 540°C and 570°C. Introduce -30 kPa high-purity ammonia gas into the quartz vacuum tube, keep it warm for 10 minutes, and then vacuumize it for 5 minutes. After repeating the intermittent cycle pumping / gas nitriding treatment for 1 hour, stop the high-frequency machine and keep the temperature Vacuumize the quartz vacuum tube to prevent oxidation of the sample surface, cool the nitriding steel sample in the quartz vacuum tube to below 300°C, take out the nitriding steel sample for re...

Embodiment 2

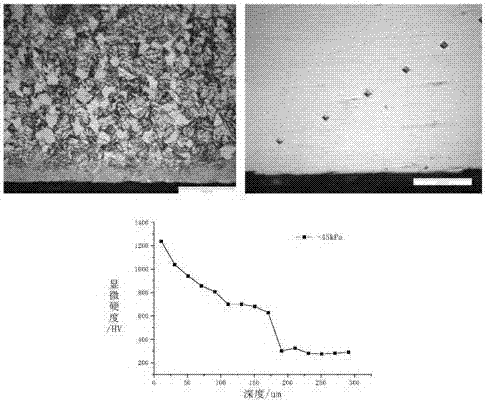

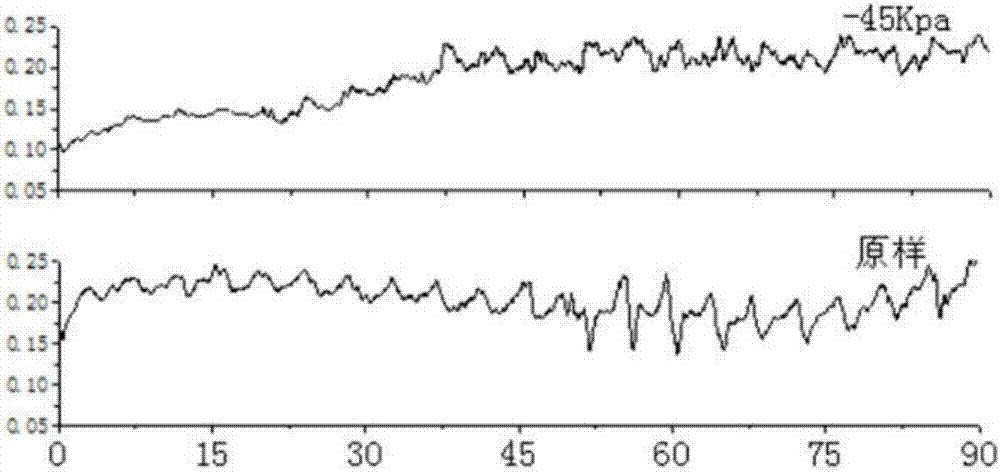

[0035] Carry out pre-treatment of 38CrMoAl nitriding steel samples (sample arrangement, cleaning and activation, etc.), put the pretreated samples into a quartz vacuum tube, seal the quartz vacuum tube, check for leaks, and introduce high-purity argon The air is driven to remove the air in the vacuum tube, and then the vacuum tube is evacuated. After reaching the vacuum requirement, the high frequency machine is turned on to inductively heat the 38CrMoAl nitrided steel sample in the vacuum tube. After the nitriding steel sample was heated to the set temperature of 560 °C, high-purity ammonia gas of -45 kPa was passed into the quartz vacuum tube, kept for 10 minutes, then vacuumed and kept for 5 minutes, and intermittent periodic pumping / gas infiltration was repeated. After nitrogen treatment for 1 h, stop the high-frequency machine, keep vacuuming the quartz vacuum tube to prevent oxidation on the surface of the sample, cool the nitriding steel sample in the quartz vacuum tube ...

Embodiment 3

[0038] Carry out pre-treatment of 38CrMoAl nitriding steel samples (sample arrangement, cleaning and activation, etc.), put the pretreated samples into a quartz vacuum tube, seal the quartz vacuum tube, check for leaks, and introduce high-purity argon The air is driven to remove the air in the vacuum tube, and then the vacuum tube is evacuated. When the vacuum requirement is met, the high-frequency machine is turned on to heat the sample in the vacuum tube. -60 kPa high-purity ammonia gas, keep it warm for 10 minutes, then vacuumize it for 5 minutes, repeat intermittent periodic pumping / gas nitriding treatment for 1 hour, stop the high-frequency machine, and keep vacuuming the quartz vacuum tube to prevent The surface of the sample is oxidized, and the nitriding steel sample in the quartz vacuum tube is cooled to below 300°C, and the nitriding steel sample is taken out for related testing to complete the entire double-pulse rapid nitriding process.

[0039] Figure 4 It is th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com