Aspirating type propulsion test simulation method based on high-temperature pulse wind tunnel

A simulation method, air-breathing technology, applied in aerodynamic tests, jet engine tests, gas turbine engine tests, etc., can solve problems such as inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

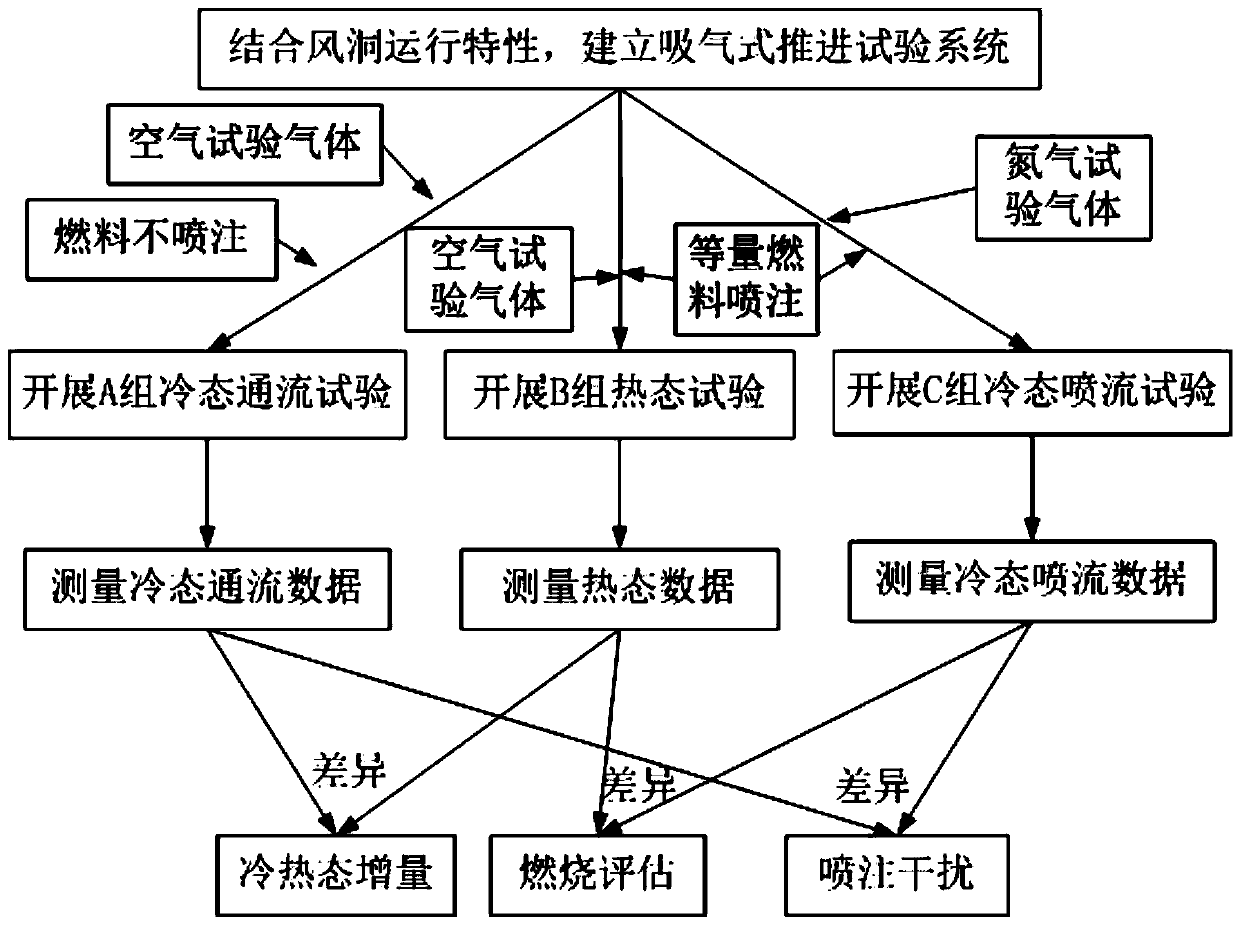

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

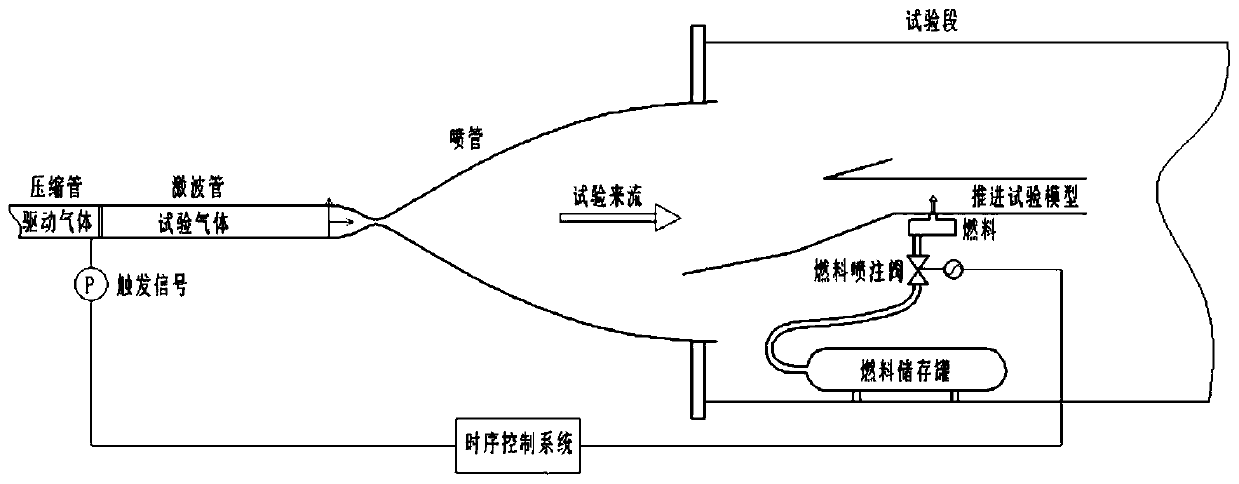

[0047] Step 1. Taking a free-piston-driven high-enthalpy shock tunnel as the implementation object, establish an air-breathing propulsion test system, such as figure 2 shown;

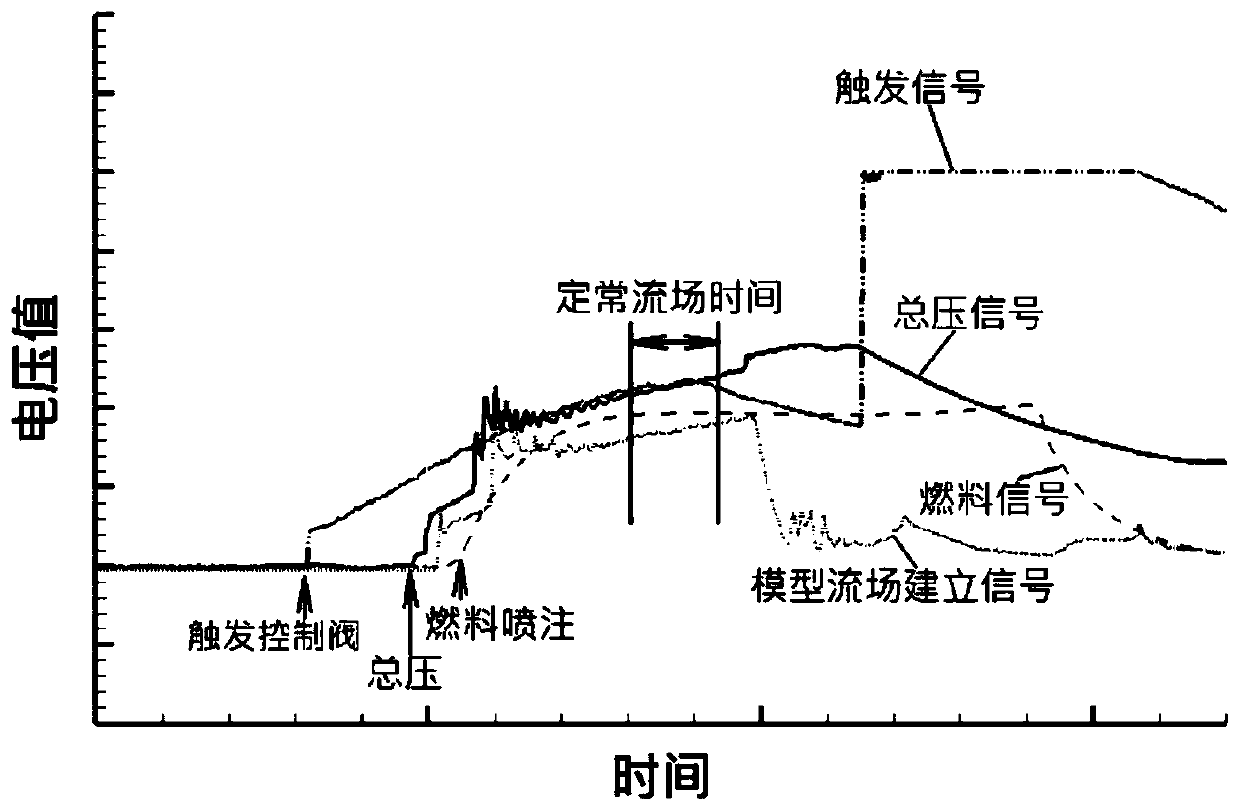

[0048] The driven section of the wind tunnel included in the air-breathing propulsion test system is a shock tube, and the test gas in the shock tube can be replaced according to requirements; the propulsion test model is a fuel vertical injection structure; the fuel injection The response time of the valve is 35ms; the response time of the sequential control system is 0.5ms, and the delay time can be set arbitrarily between 0 and 500ms; the sudden change moment of the pressure monitoring signal at the end of the wind tunnel 2.5m from the end of the compression tube is shorter than that of the wind tunnel shock wave The sudden change time of the total pressure signal at the end of the pipe is 50ms earlier, and the detection signal at this place is selected as the trigger signal; the wind tunnel test ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com