Rice draining cooking technology

A technique of draining rice and technology, which is applied in the field of preparation of drained rice and steamer rice, which can solve the problems that water and rice cannot be separated, cannot be cooked with drained rice cooker, and rice cannot be steamed, and achieve the effect of increasing appetite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

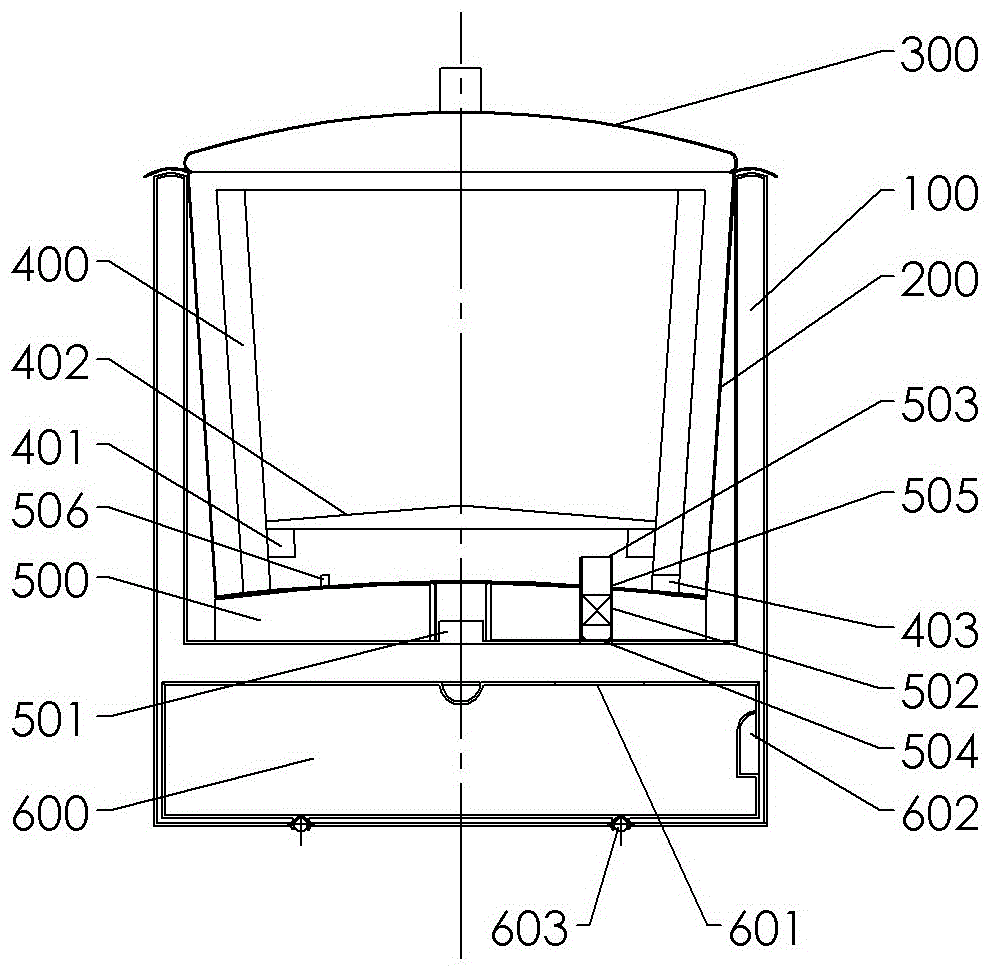

[0041] Embodiment one is basically as attached figure 1 As shown: the electric rice cooker in the embodiment includes a housing 100 as the main body, an inner tank 200 is placed in the housing, a pot cover 300 is arranged above, a steamer is placed in the inner tank, the steamer wall 400 is barrel-shaped, and the steamer wall 400 is barrel-shaped. A protruding retort bottom block 401 is provided on the inner side of the wall, and the retort bottom is placed on the retort bottom stopper to fix it. The retort bottom 402 is a circular metal plate with a certain taper, in the shape of a bucket hat, and there are multiple Filter holes, rice grains will not fall from the small filter holes, there is sufficient space for water between the bottom of the retort and the bottom of the inner tank. The lower part of the retort wall forms a retort foot and falls on the bottom of the liner. The retort foot is provided with a plurality of water holes 403, and the water holes can be semicircul...

Embodiment 2

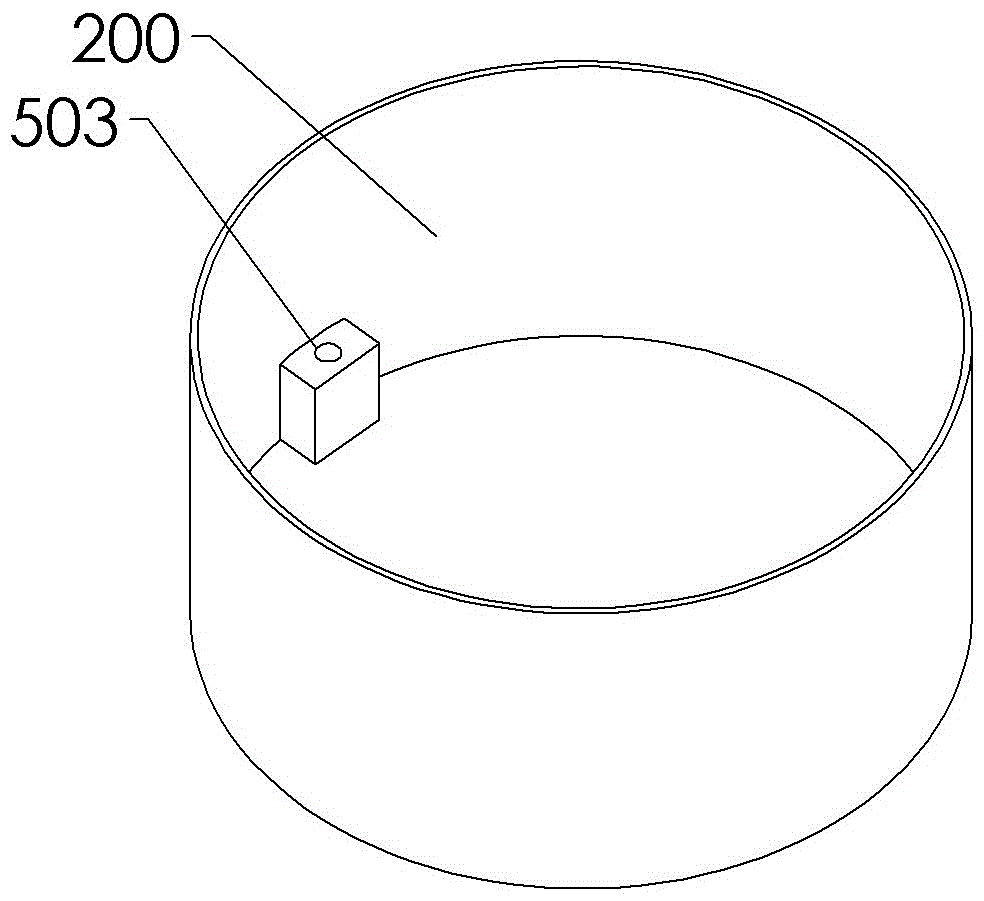

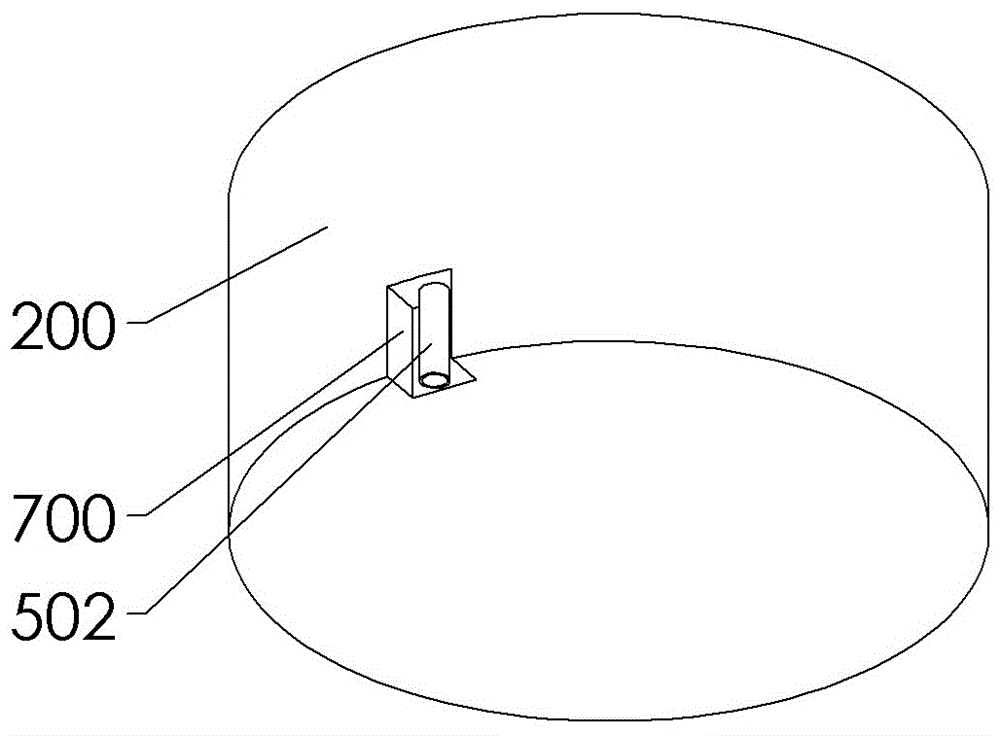

[0048] Example two such as figure 2 , 3 as shown, figure 2 It is observed from a top view angle, and the inner wall part of the liner can be seen. image 3 If you look up, you can see the outer wall of the liner. The difference from Embodiment 1 is that the heating plate, the temperature sensor and the liner are arranged according to the method in the background art, that is, the liner is movably placed on the heating plate without connecting parts therebetween. A groove 700 is opened on the outer wall below the inner tank, and the bottom and sides of the groove are open. Above (that is, the bottom of the groove), the solenoid valve 502 is embedded in the groove and fixed by bolts. The solenoid valve can be connected with an external circuit to realize its work control. The inlet of the solenoid valve is connected with the drain port 503, and the outlet of the solenoid valve can pass through The hose is connected to the rice soup box. Of course, the groove can also be a...

Embodiment 3

[0049] Embodiment three such as Figure 4 As shown, the difference from the above-mentioned embodiment (such as Embodiment 1) is that an annular groove 800 is provided on the inner wall of the inner container 200, and the annular groove can be formed during the stamping process of the inner container. The opening of the annular groove is upward, and the lower end of the plank forming the side wall of the retort is embedded in the annular groove 800. A circle of planks forms the retort wall 400 of the retort, and the upper part of the retort wall is embedded in a movable annular collar 900. The opening of the groove is downward, and the collar and the annular groove face up and down to fix the plank as the retort wall on the inner wall of the inner container, and a spacer is bonded between the outer side of the upper part of the retort wall and the inner container. The inner side wall of the retort wall 400 is connected with four protruding retort bottom stoppers 401 by nails, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com