Low-bath-ratio high-temperature pulse type jet dyeing machine

A pulse type, low liquor ratio technology, applied in the field of dyeing machinery, can solve the problems of low dye concentration, increase dye discharge, low fuel concentration, etc., achieve obvious economic and social benefits, save additives, and reduce waste liquid discharge Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with specific embodiments, but the protection and implementation of the present invention are not limited to this. It should be pointed out that, if there are any points that are not specifically described below, those skilled in the art can understand with reference to the prior art or realized.

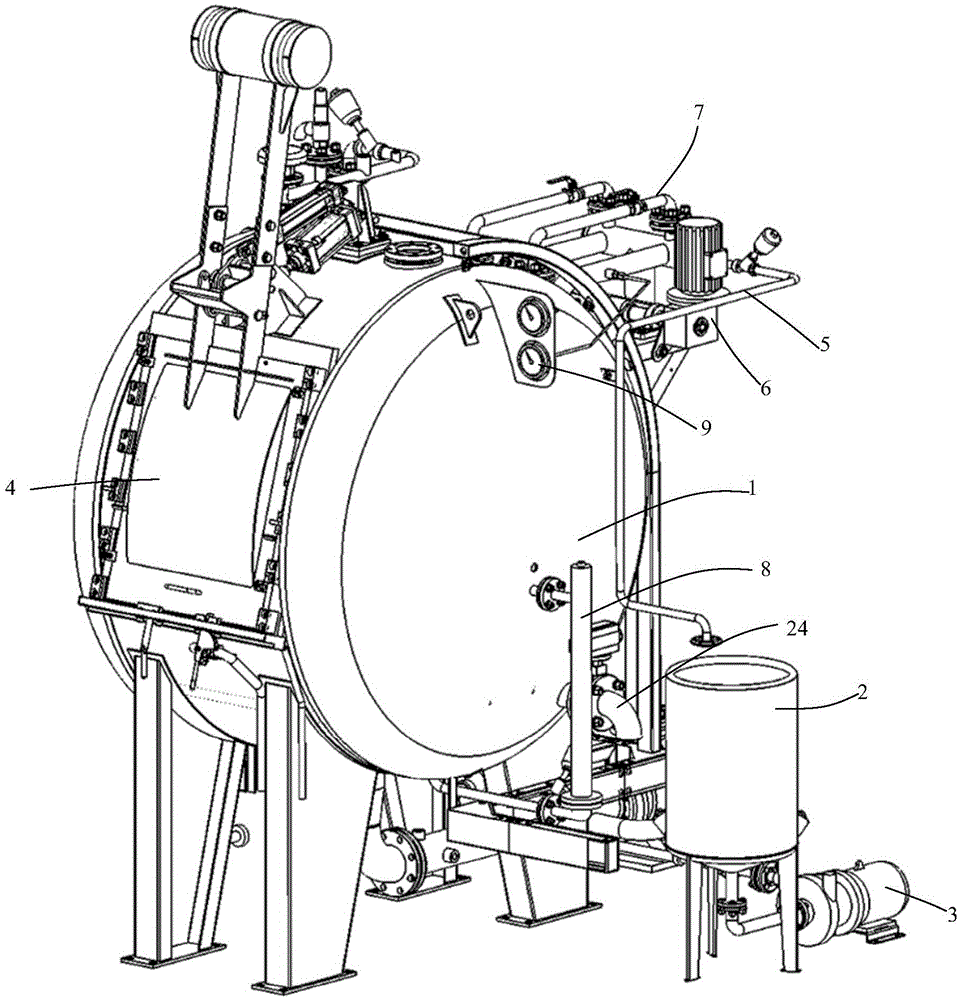

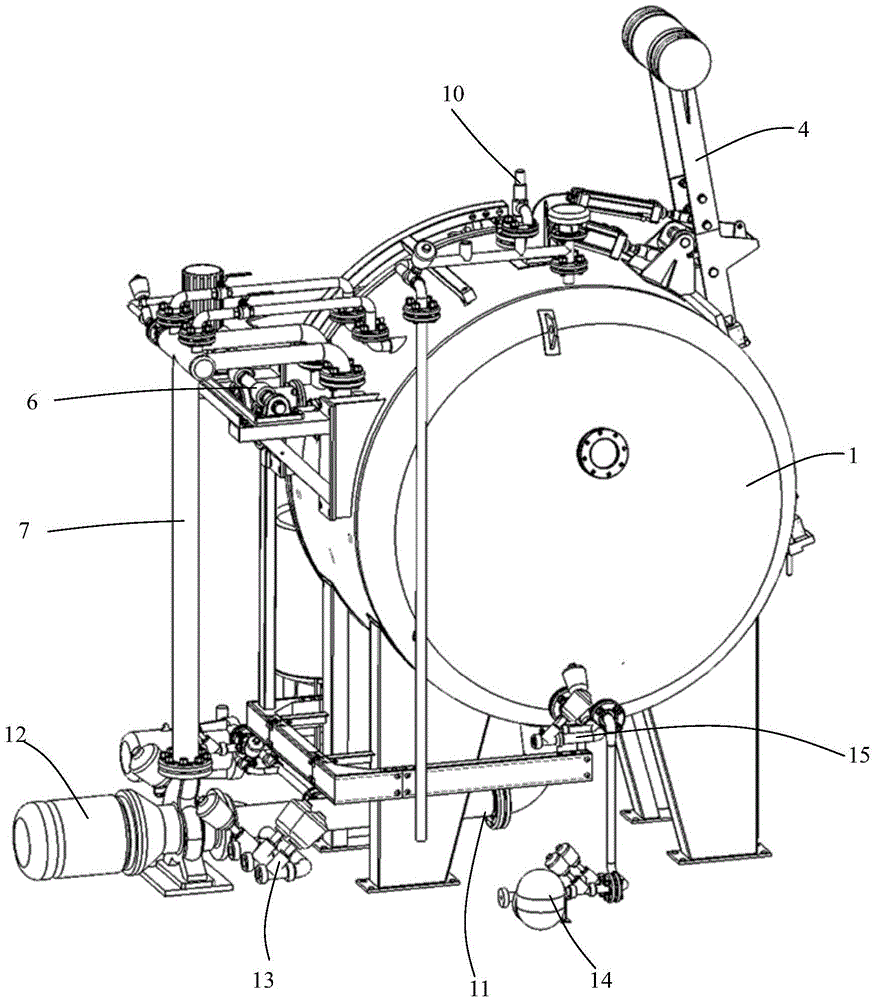

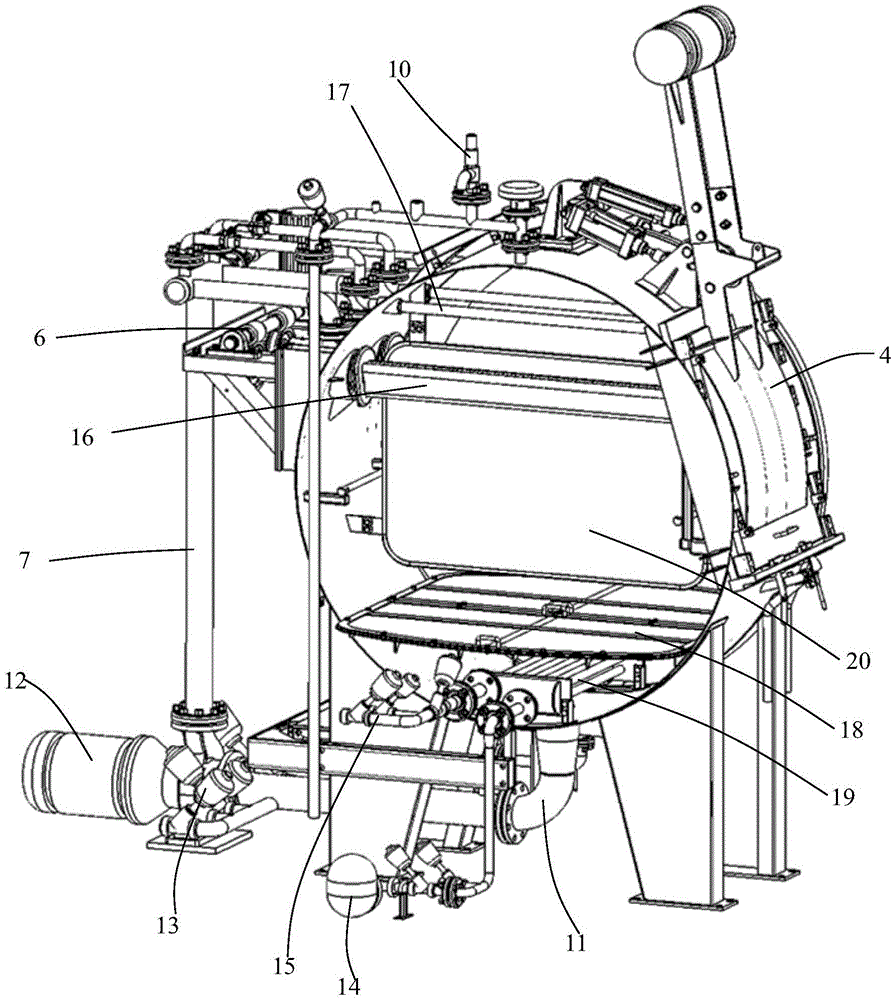

[0034] like Figure 1~Figure 9 As shown in the figure, a low liquor ratio high temperature pulse jet dyeing machine mainly includes a main tank 1, an auxiliary tank 2, a liquid addition pump 3, a cylinder head assembly 4, an auxiliary tank liquid return pipe 5, a motion system 6, and a dye liquor shunt pipe. 7. Liquid level gauge 8, pressure gauge 9, pressure relief valve 10, main cylinder return pipe 11, main pump 12, feeding valve group 13, steam trap assembly 14, coil steam inlet 15, star nozzle 16, flower The spray nozzle 17, the filter screen 18, the heat exchanger 19, the partition plate 20, the nozzl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com