High-temperature pulse test system for hydraulic hose

A technology of pulse testing and hydraulic hose, applied in the direction of applying repeated force/pulsation force to test material strength, measuring devices, instruments, etc., can solve problems such as manual debugging, slow update, slow update, etc., to achieve true test data and measurement The result is accurate and the effect of avoiding contamination

Inactive Publication Date: 2018-12-18

HARBIN UNIV OF SCI & TECH

View PDF5 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] With the formulation and implementation of various standards for rubber and other hoses, a corresponding pressure pulse test system for testing hoses has emerged. Compared with the mature rubber and other hose testing technologies in developed countries, the development of various aspects in China is relatively lagging behind, the test and testing standards are not complete, and the update is slow, the development of test equipment is also r

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

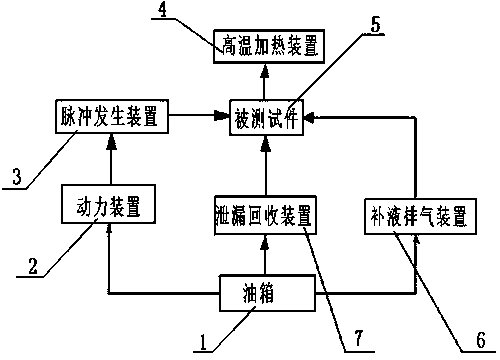

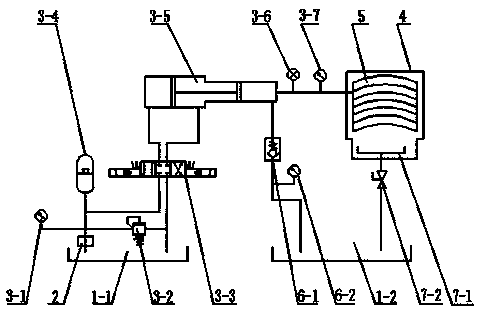

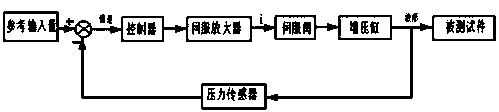

The invention relates to a hydraulic pulse test system for testing the fatigue life of a hose such as a rubber pipe under high-temperature pulse pressure, and test pressure can be controlled. The system comprises an oil tank, a power device, a pulse generation device, a tested piece, a high-temperature heating device, a liquid supplementing and gas exhaust device and a leakage recycling device. The oil inlet and outlet of the oil tank are respectively connected with the oil inlet and outlet of the power device; the oil inlet and outlet of the power device are respectively connected with the oil inlet and outlet of the pulse generation device; the pulse generation device is connected with the tested piece; the tested piece is arranged in the high-temperature heating device; an oil outlet ofthe liquid supplementing and gas exhaust device is connected to the tested piece; the leakage recycling device is mounted below the tested piece; and an oil outlet of the system is connected to the oil tank of the liquid supplementing device.

Description

technical field [0001] The invention relates to a high-temperature pulse test system for hose hydraulic equipment such as rubber hoses. In particular, it relates to a fatigue life test system for hoses working in a high-temperature pulse environment. Background technique [0002] With the formulation and implementation of various standards for rubber and other hoses, a corresponding pressure pulse test system for testing hoses has emerged. Compared with the mature rubber and other hose testing technologies in developed countries, the development of various aspects in China is relatively lagging behind, the test and testing standards are not complete, and the update is slow, the development of test equipment is also relatively backward, and some even have manual debugging; compared with the slow update of domestic standards, Japan has already High temperature pulse test items are mandatory. [0003] Most domestically produced rubber hose and other hose testing systems still...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/36

CPCG01N3/36G01N2203/001G01N2203/0048G01N2203/0073G01N2203/0226G01N2203/0274

Inventor 赵新通康静王云周雷天圻

Owner HARBIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com