Experimental simulation device and simulation method for temperature-pressure pulse composite cracked coal

An experimental simulation, temperature pulse technology, applied in measuring devices, using stable tension/pressure to test material strength, instruments, etc., can solve the uncertainty of experimental results, different stress states, increased experimental costs in the underground environment of coal mines, and Dangerous and other problems, to achieve the effect of compact structure, simple operation, convenient installation and layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

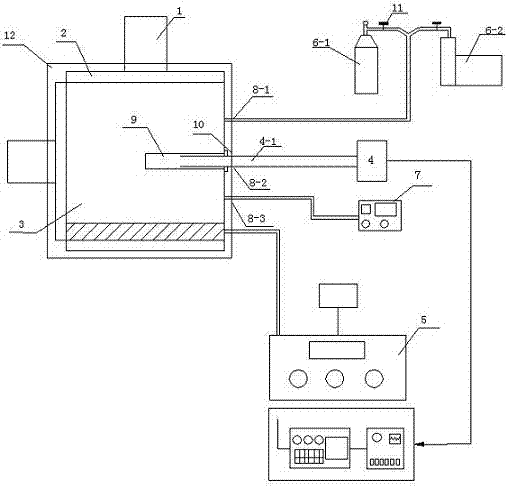

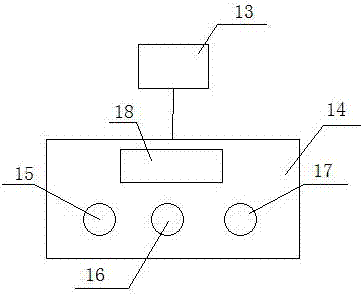

[0024] Such as figure 1 and 2 As shown, an experimental simulation device for temperature-pressure pulse combined fracturing coal body, including closed triaxial pressurization device, temperature-pressure pulse combined fracturing device, vacuum pumping and gas injection device and monitoring device; temperature-pressure pulse combined fracturing device The device includes a temperature pulse generating device 5 and a high-pressure pulse water pump 4, wherein the temperature pulse generating device 5 includes a temperature sensor 13 and a temperature regulating device; the vacuum pumping and gas injection device includes a vacuum pump 6-2 and a gas injection cylinder with a pressure gauge 6-1, and connected to the coal body through a three-way valve; the three-axis pressurization device includes a coal sample tank 12, the three inner sides of the coal sample tank 12 are provided with a pressure plate 2, and the outer side of the pressure plate is vertically provided with a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com