Sterilizing device sprinkling high-temperature pulse hot water

A technology of hot water spraying and sterilizing equipment, which is applied in food science, food preservation, application, etc., and can solve the problems that are difficult to reach and cannot kill microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

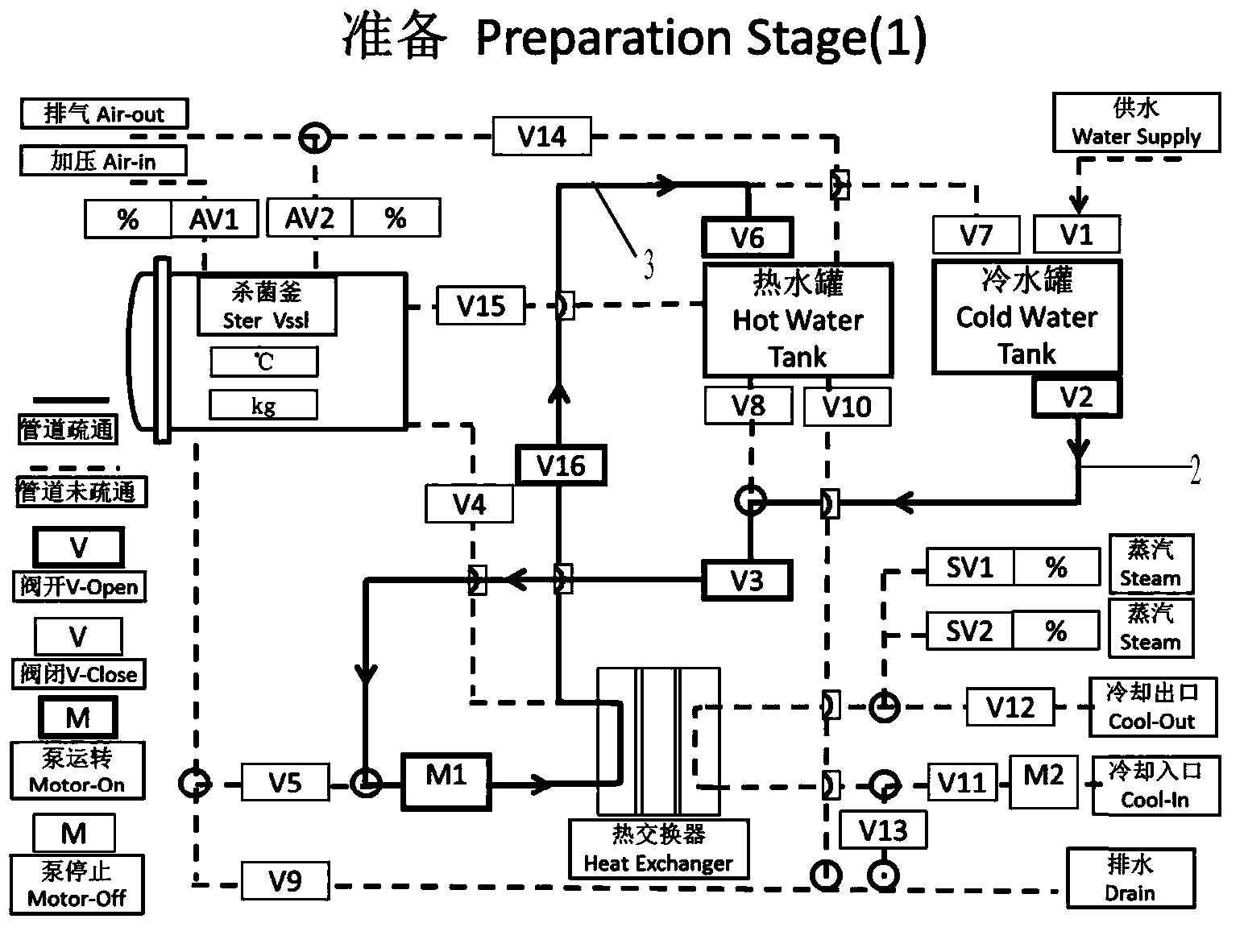

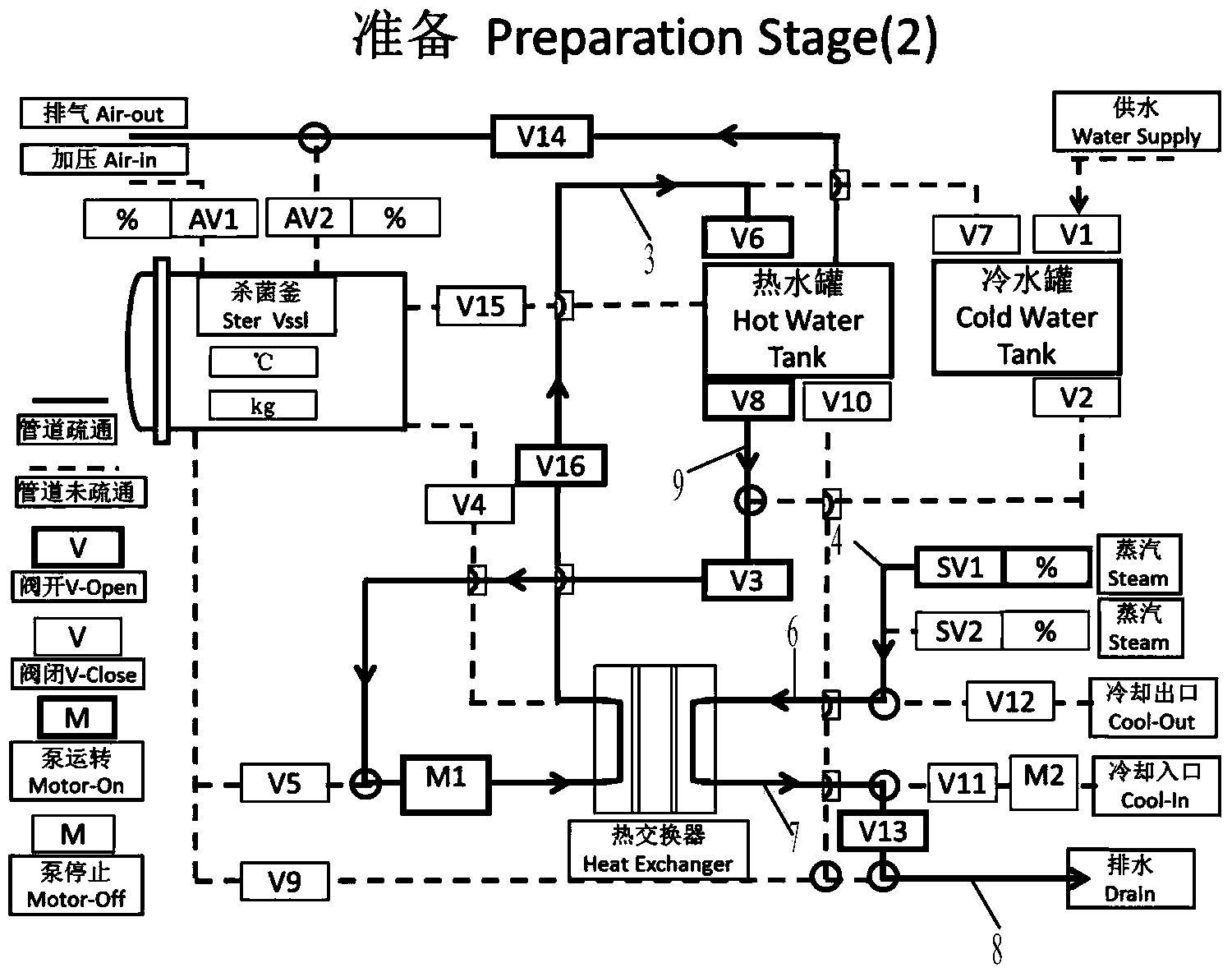

[0029] Below in conjunction with specific embodiment the present invention is described in further detail:

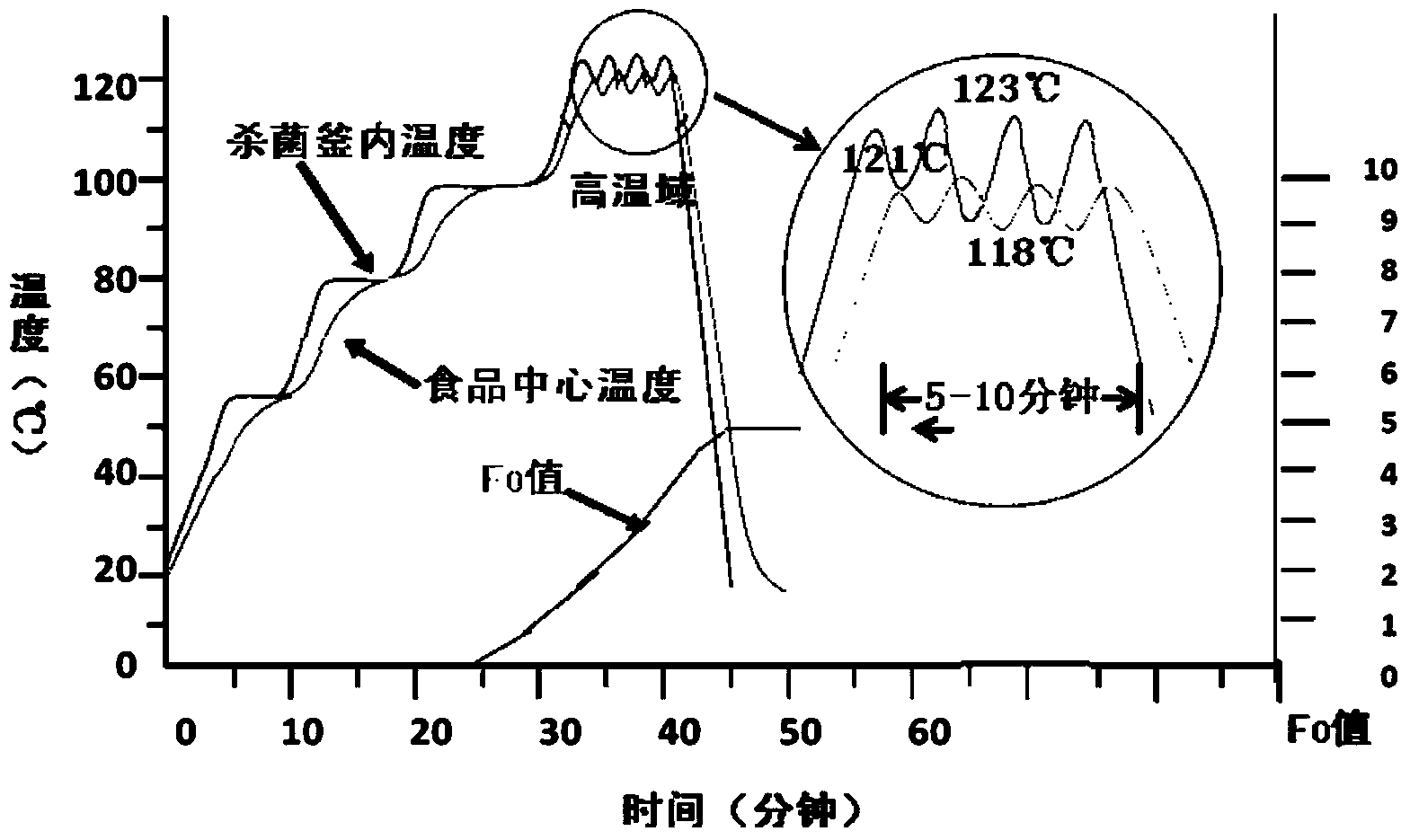

[0030] Such as figure 1 As shown, the high-temperature pulsation sterilization method adopted by the device of the present invention is based on the theory of F0 value sterilization technology and the principle that microorganisms are easily killed quickly due to sharp temperature fluctuations at high temperatures. On the basis of multi-stage heating, when the core temperature of the food has reached a relatively high high-temperature stage, through the steam proportional valve with arbitrary opening and fine adjustment, the hot water is adjusted through the heat exchanger, and the hot water is precisely adjusted. The temperature in the kettle of the spraying device fluctuates rapidly and changes continuously for many times, forming a high-temperature pulsating hot water temperature change curve.

[0031] Within the variable temperature range, the range and duration of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com