Temperature sensor integrated in RFID tag

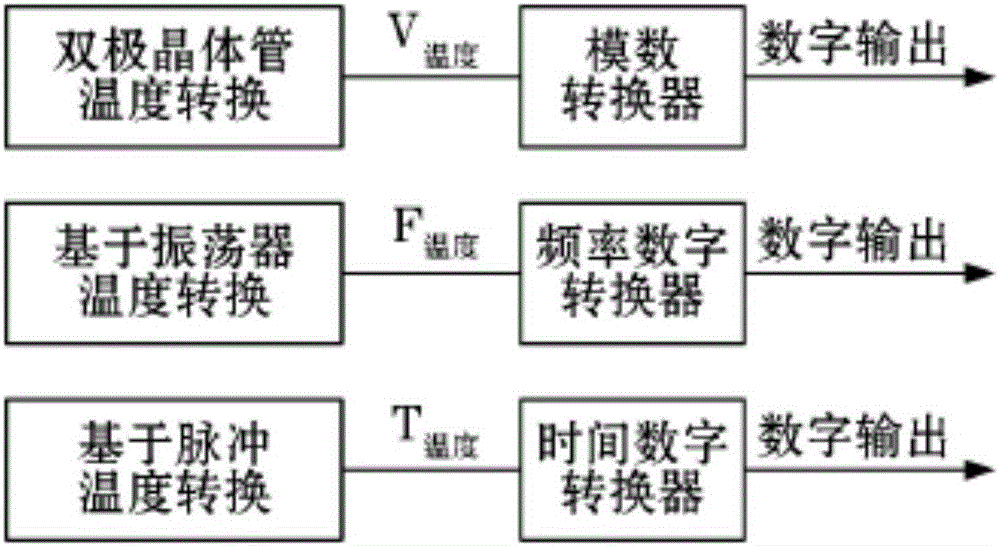

A technology of RFID tags and temperature sensors, applied in the field of RFID, can solve problems such as chip area power reduction, area and energy consumption, unfavorable costs, etc., and achieve the effects of chip area reduction, power consumption reduction, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

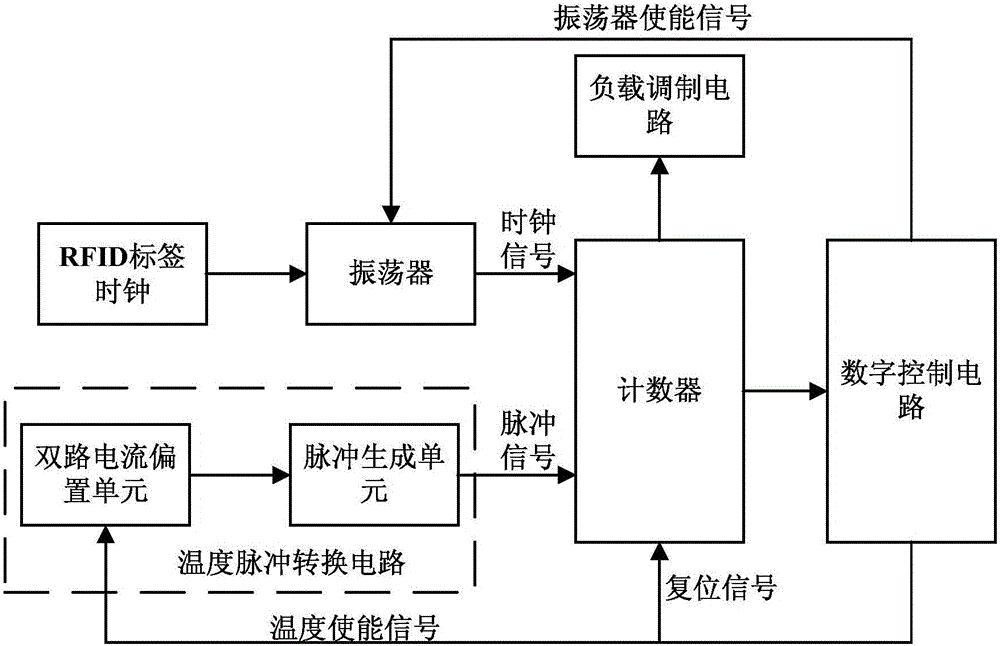

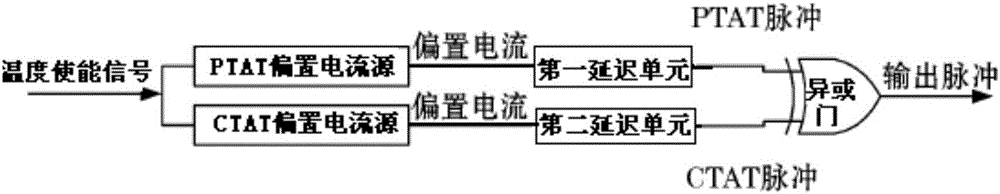

[0026] Aiming at the problem that there are relatively few shared module circuits between the temperature sensor and other modules in the prior art, the present invention proposes a brand-new temperature sensor integrated in the RFID tag. The system structure of the temperature sensor is as follows: figure 2 As shown, it is mainly composed of temperature pulse conversion circuit, counter, digital control circuit, oscillator, RFID tag clock and load modulation circuit. The working principle of the present invention is as follows:

[0027] When the system is working, firstly, the digital control circuit sends a control signal to the oscillator to make it output the system clock according to the RFID tag clock. After the system clock works, the digital control circuit sends a reset signal to clear the counter, and at the same time sends a temperature enable signal to the temperature pulse conversion circuit to control it to start collecting temperature information. After the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com