High-temperature resisting and soundproofing anti-skidding door cover for high-temperature pulse bag type dust collector

A pulse dust collector, high temperature resistant technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of affecting the surrounding environment, easy to burn, unsafe and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with drawings and embodiments.

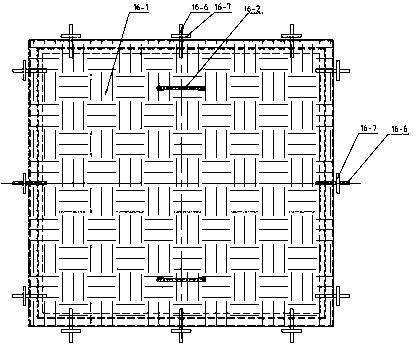

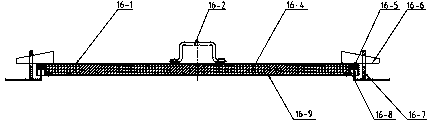

[0011] As shown in the figure, the high-temperature bag-type pulse dust collector has a high-temperature noise-resistance and anti-slip door cover, including a folded cover plate 16-1 with folded edges, sealing strips around it, cover plate handle 16-2, and a cover plate 16-1. 1 The positioning fixing plate 16-7 and the right-angled trapezoidal pin 16-6 of the fixed door cover around the surface, the cover plate handle 16-2 is arranged on the surface of the cover plate 16-1, the cover plate 16-1 adopts anti-skid pattern steel, and the cover plate 16- 1 The interior is equipped with high-temperature-resistant heat-insulating and sound-absorbing cotton 16-4, and the surroundings of the high-temperature-resistant heat-insulating and sound-absorbing cotton 16-4 are equipped with inner baffles 16-8, and the inner baffles 16-8 and the folded edges of the cover form a sealing g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com