Patents

Literature

30results about How to "Not distorted" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

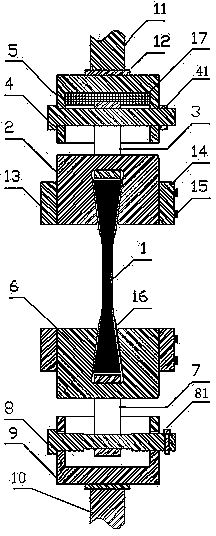

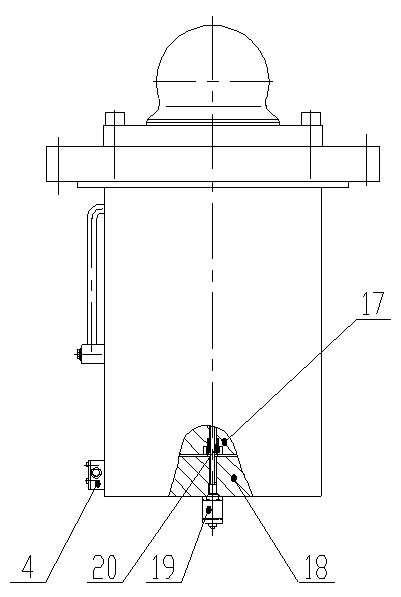

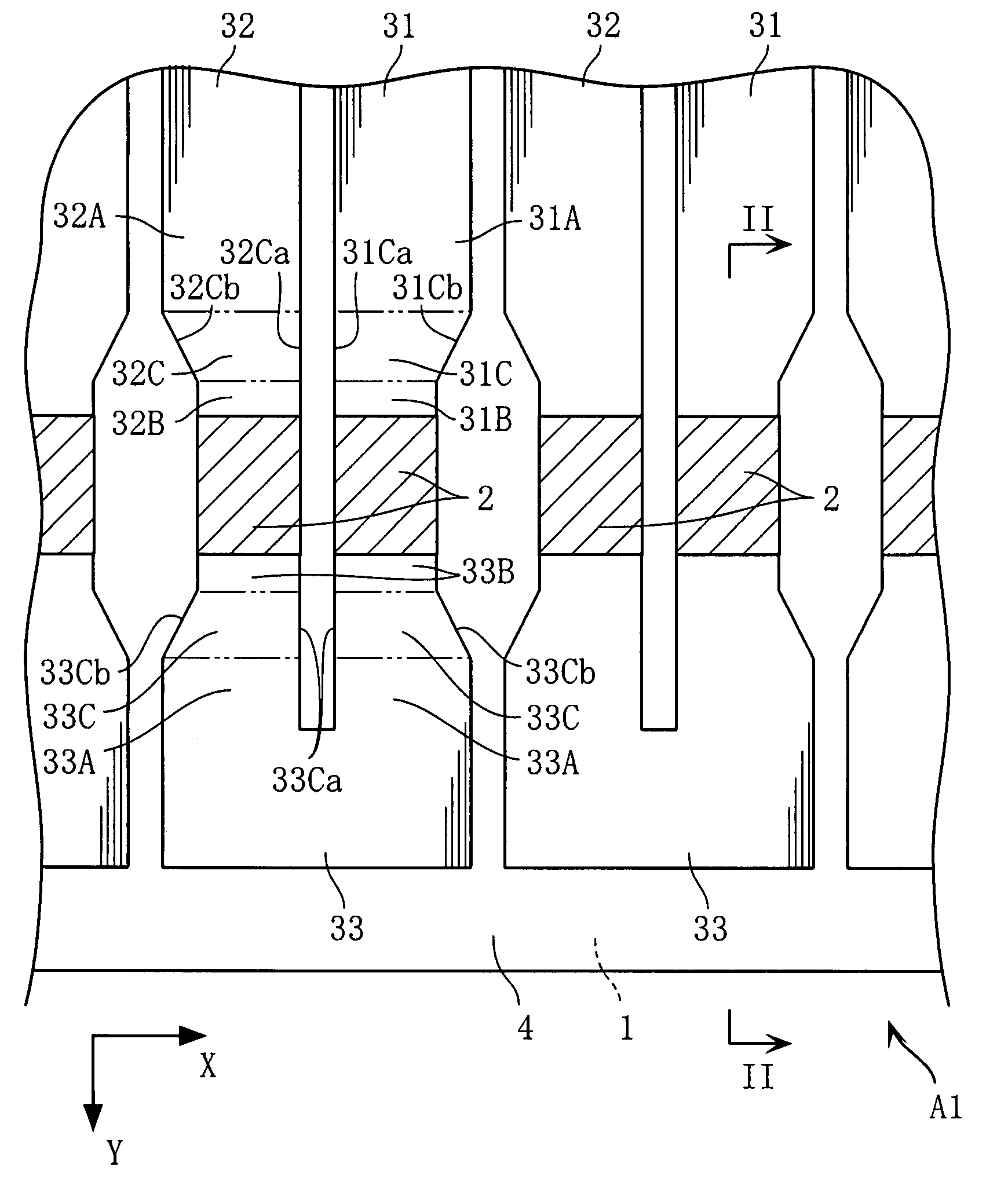

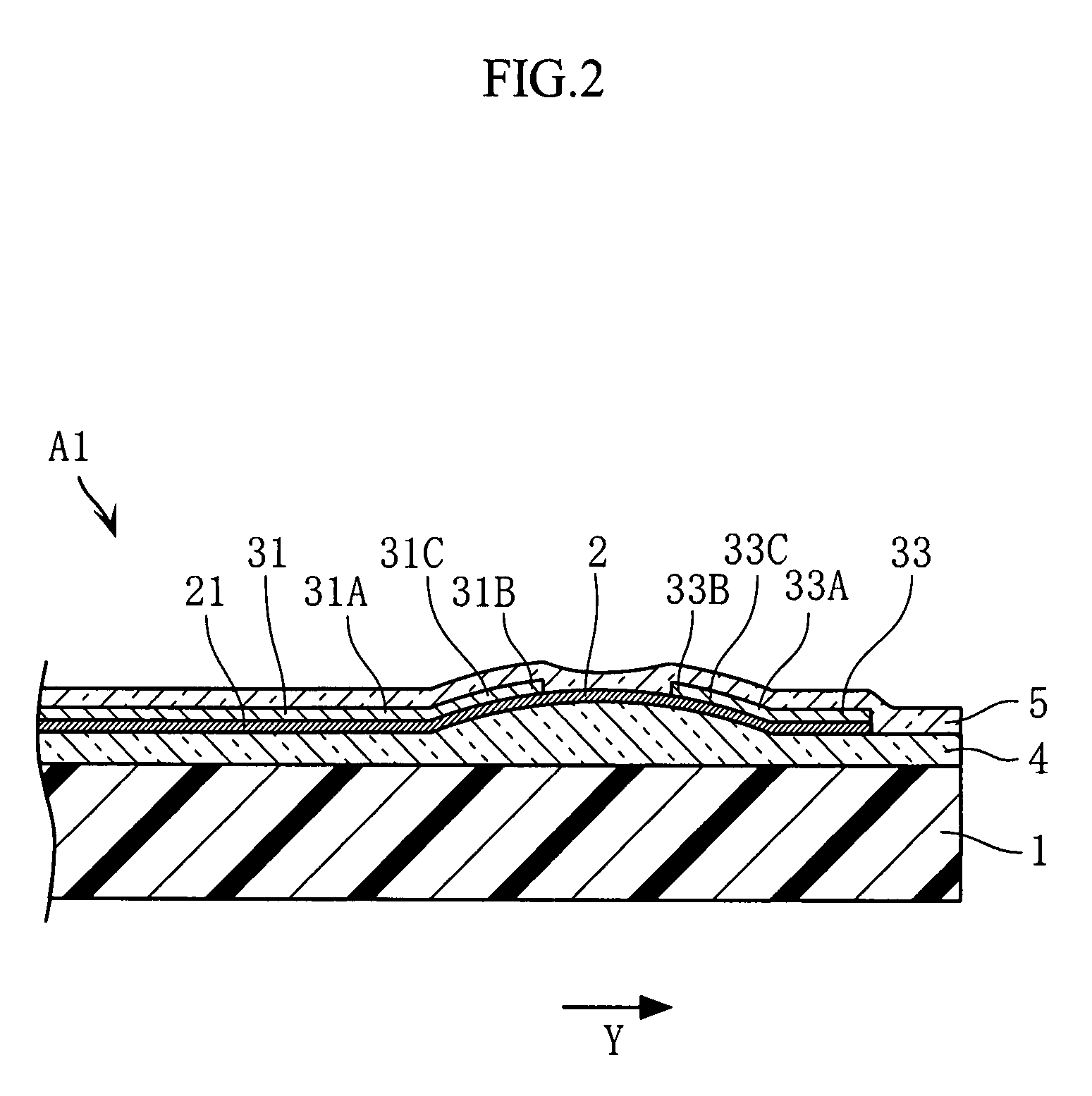

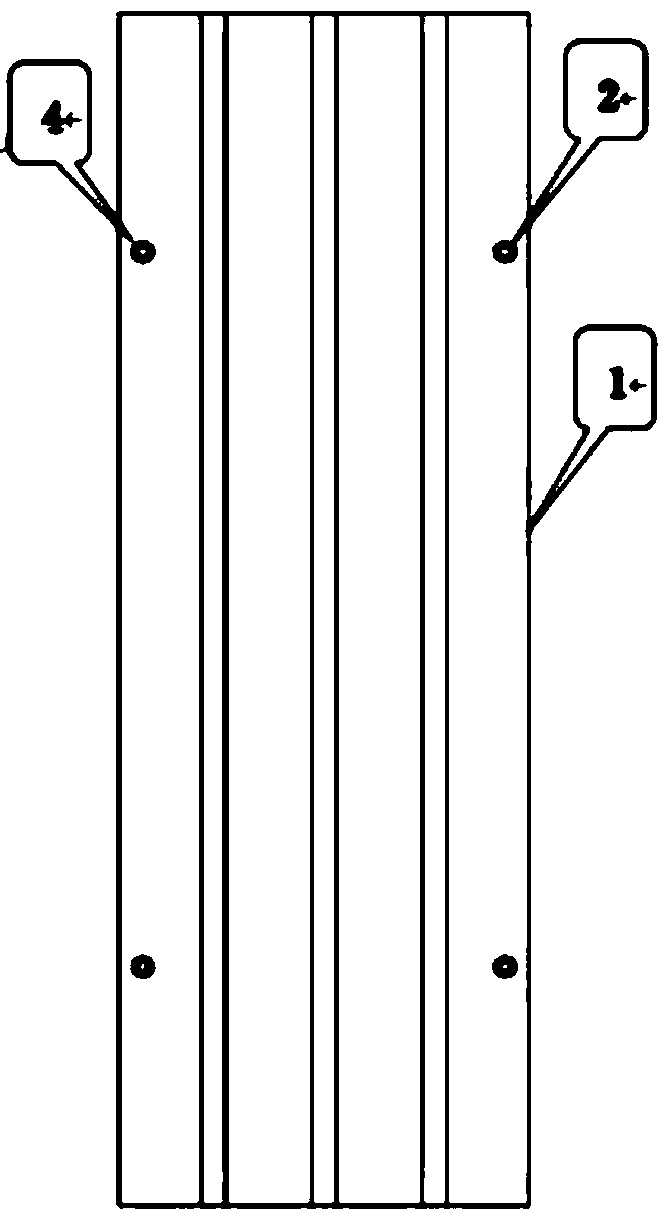

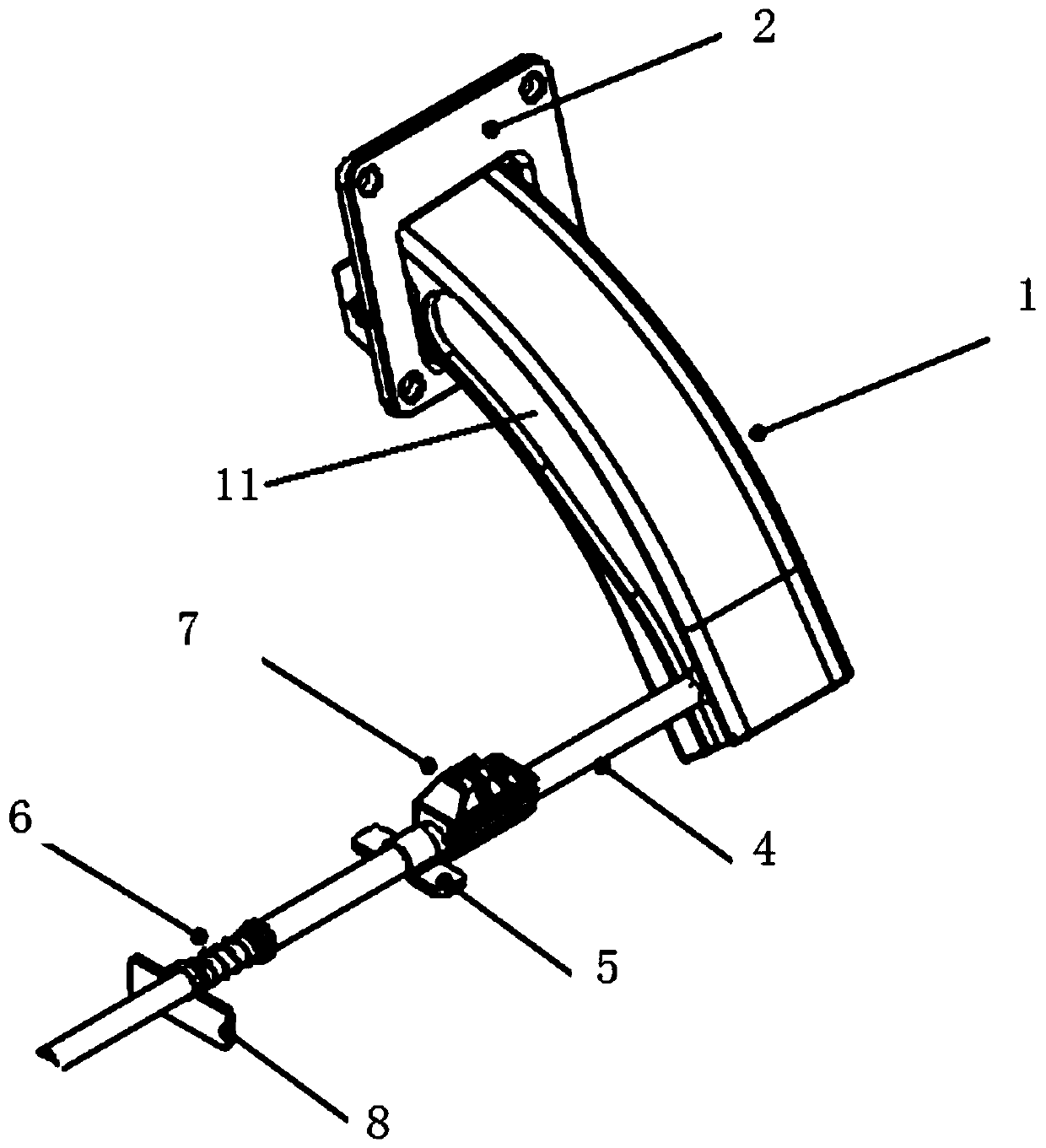

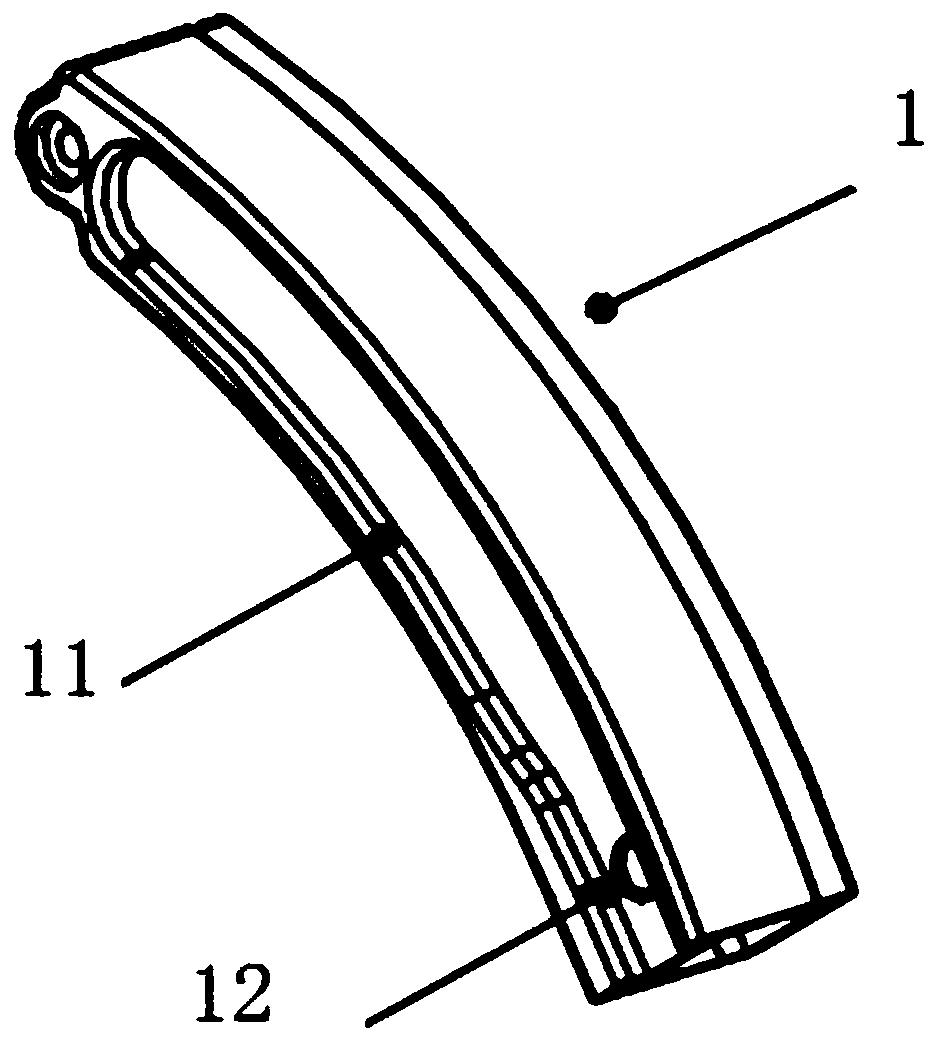

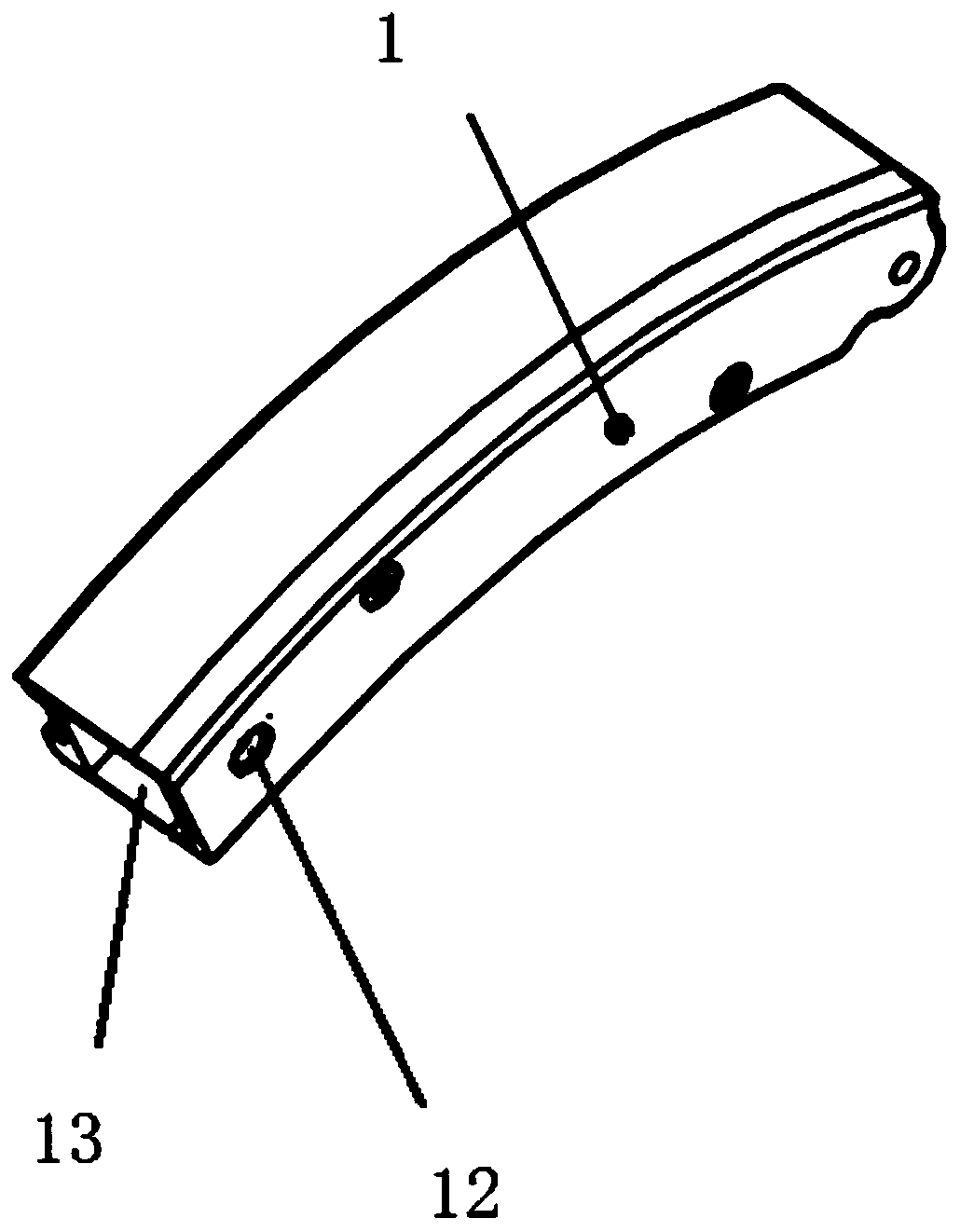

Clamping mechanism of testing device for direct tensile strength of fragile material

InactiveCN104330304ANot distortedNot subject to bendingMaterial strength using tensile/compressive forcesCold testUltimate tensile strength

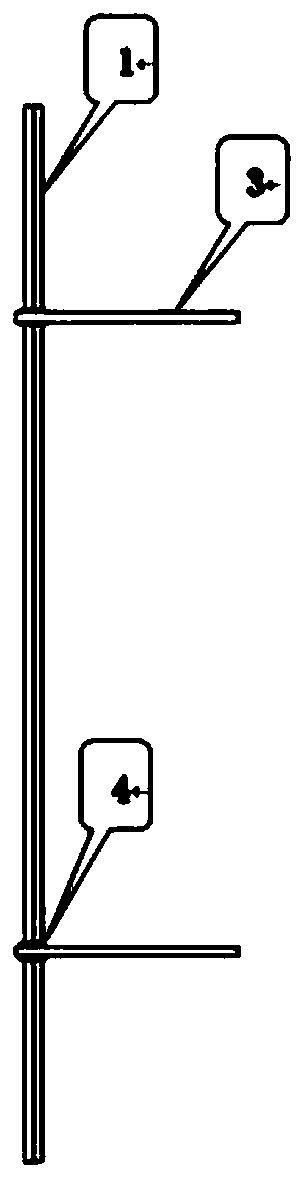

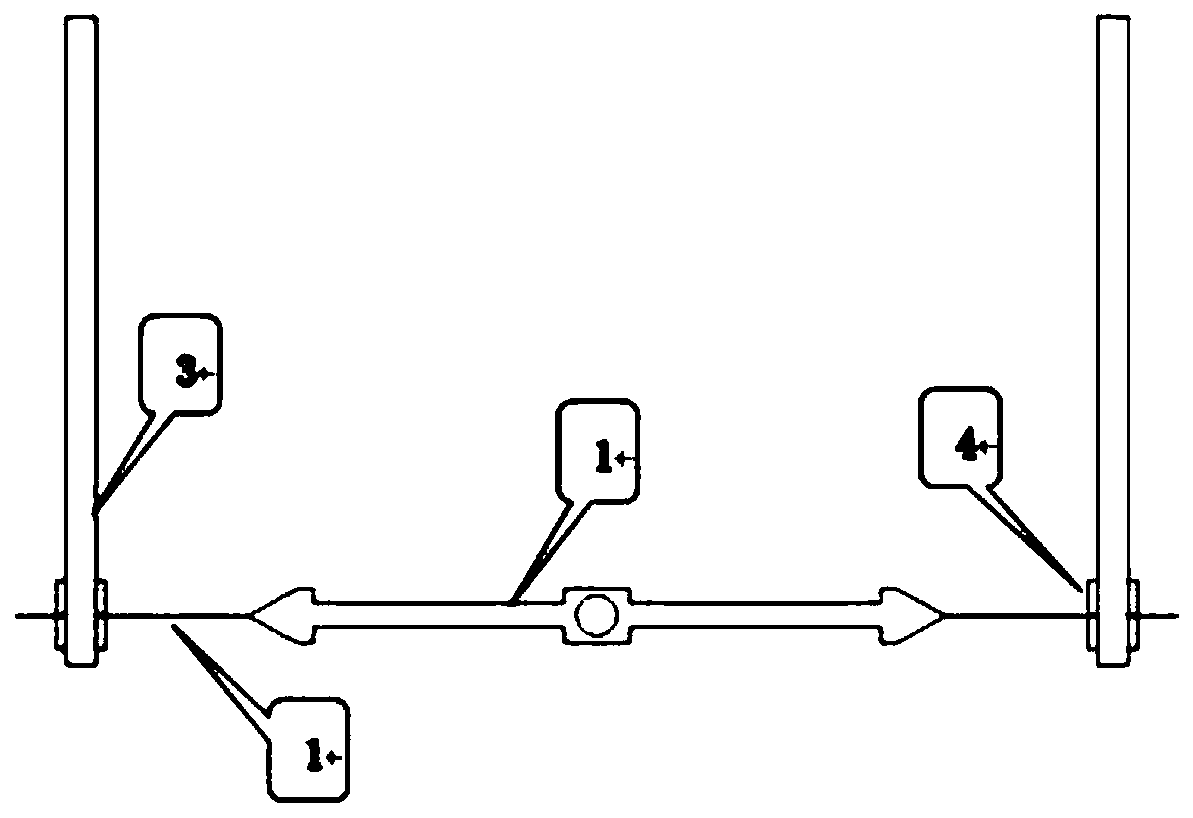

The invention discloses a clamping mechanism of a testing device for the direct tensile strength of a fragile material. The clamping mechanism comprises an upper clamping component and a lower clamping component, wherein the upper clamping component comprises an upper wedge-shaped clamp (2) which is hung on an upper cylindrical pin (4) of an upper cylinder (5) through an upper circular ring (3), the upper cylindrical pin (4) is mounted on a pin hole of the upper cylinder (5), and the upper cylinder (5) is connected with an upper pulling rod (11); the lower clamping component comprises a lower wedge-shaped clamp (6) which is connected to a lower cylindrical pin (8) of a lower cylinder (9) through a lower circular ring (7), the lower cylindrical pin (8) is mounted on a pin hole of the lower cylinder (9), and the lower cylinder (9) is connected with a lower pulling rod (10) of a testing machine. The clamping mechanism has the advantages that a test piece is prevented from being bent and distorted in the direct tensile process of the fragile material, and the clamping of the wedge-shaped clamps to the test piece is improved; the clamping mechanism is applicable to indoor temperature testing, high temperature testing and low temperature temperature.

Owner:CHONGQING UNIV

Method for duplicating and enlarging sculpture

InactiveCN104015535ASolve difficult crafting puzzlesConsistent proportionModel makingEngraving3d printer

The invention belongs to the technical field of statue engraving, and relates to an engraving method, in particular to a method for duplicating and enlarging a sculpture. The method overcomes the defects in the prior art, and saves time and labor, the enlarged sculpture is not distorted, and the method can be used for producing large products. According to the technical scheme, a model of a large sculpture is scanned in a three-dimension scanner to form an electronic model, the model is sliced to be processed and then is processed through a flat carving machine, and processed slices are bonded and then ground and corrected to be molded. Compared with a traditional sculpture enlarging method, the large sculpture is sliced to be processed, and then the processed slices are bonded, so that a manufactured sculpture is larger, the size of the sculpture is far beyond the largest range of a 3D printer and a circular carving machine, and the problem that a large sculpture is hard to manufacture is solved.

Owner:SHANXI BIMU MOER BUILDING TECH CO LTD

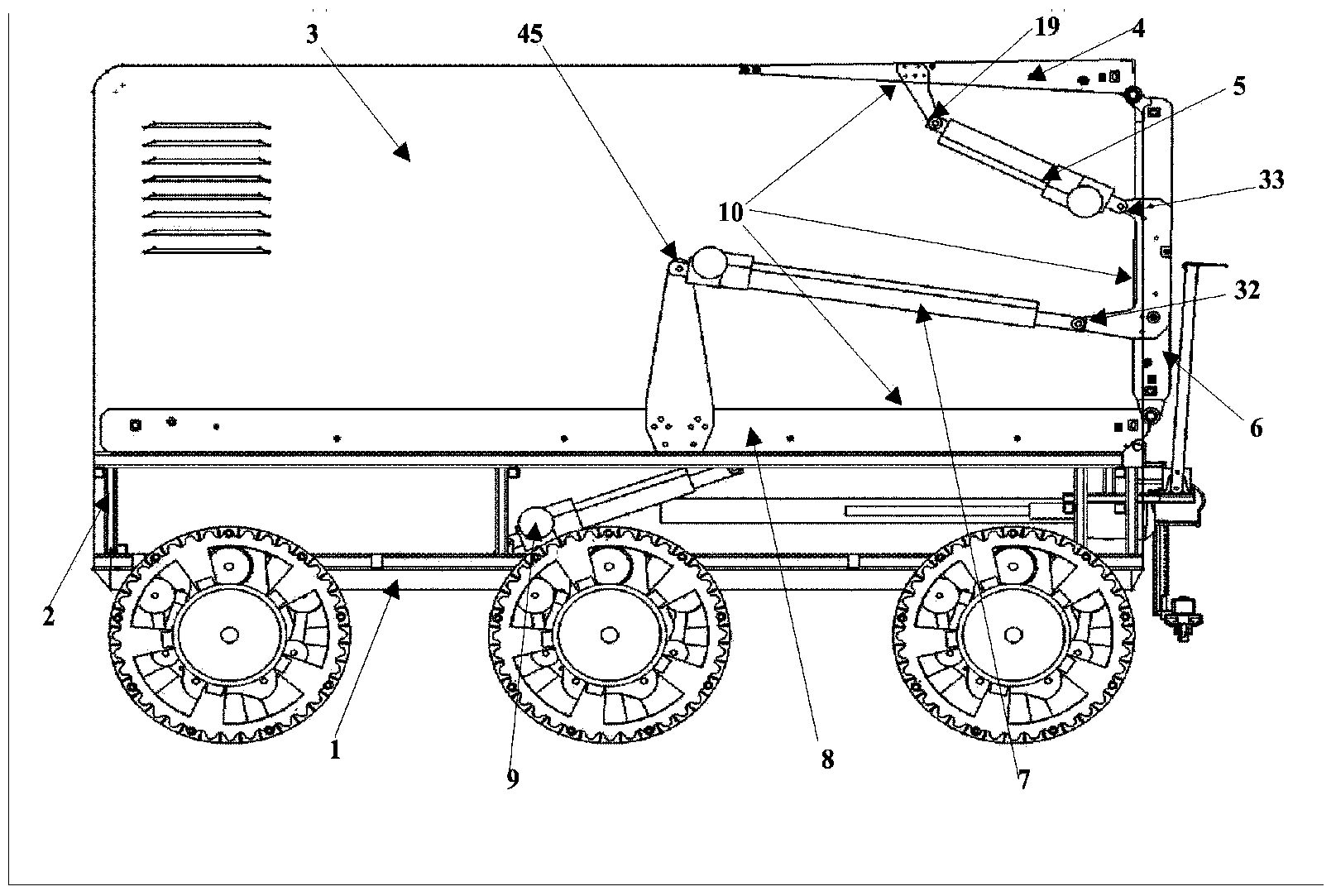

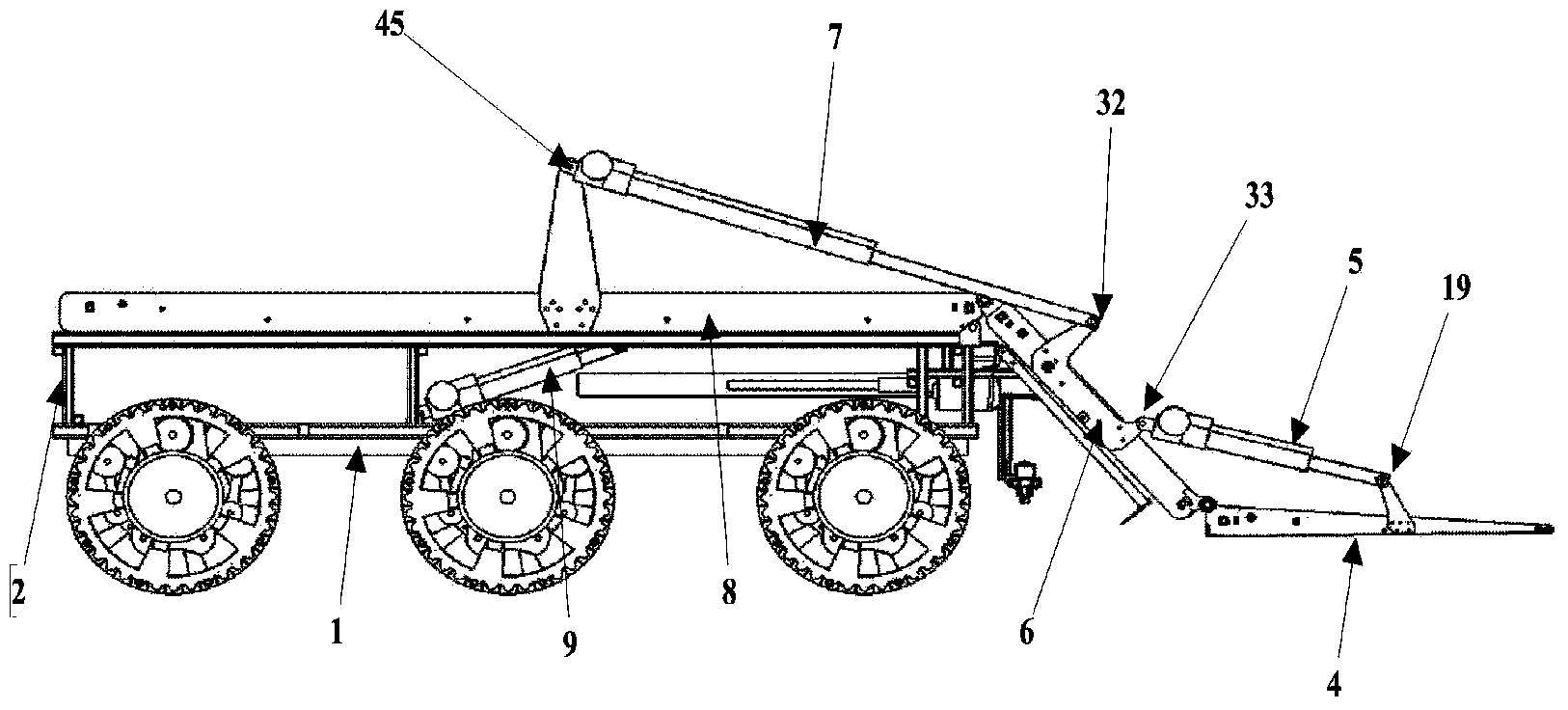

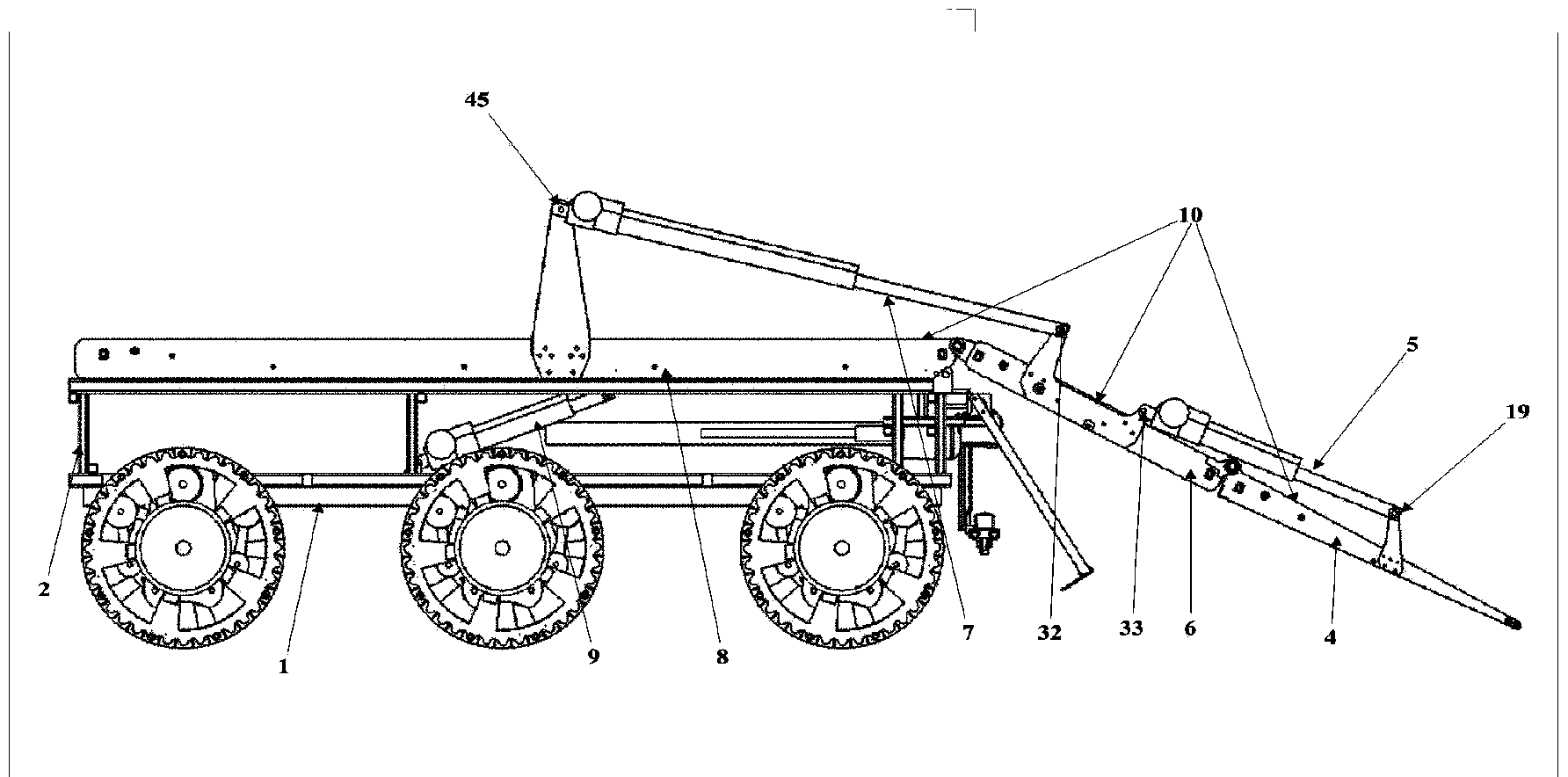

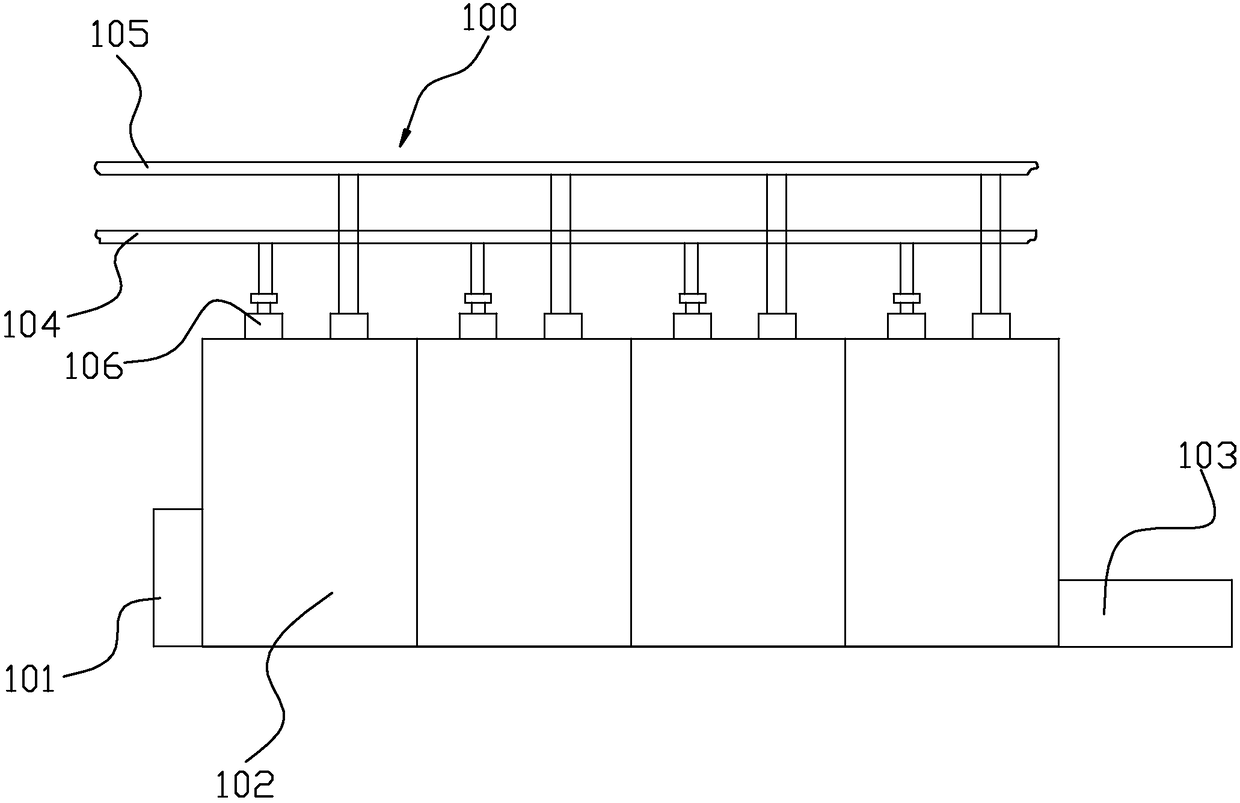

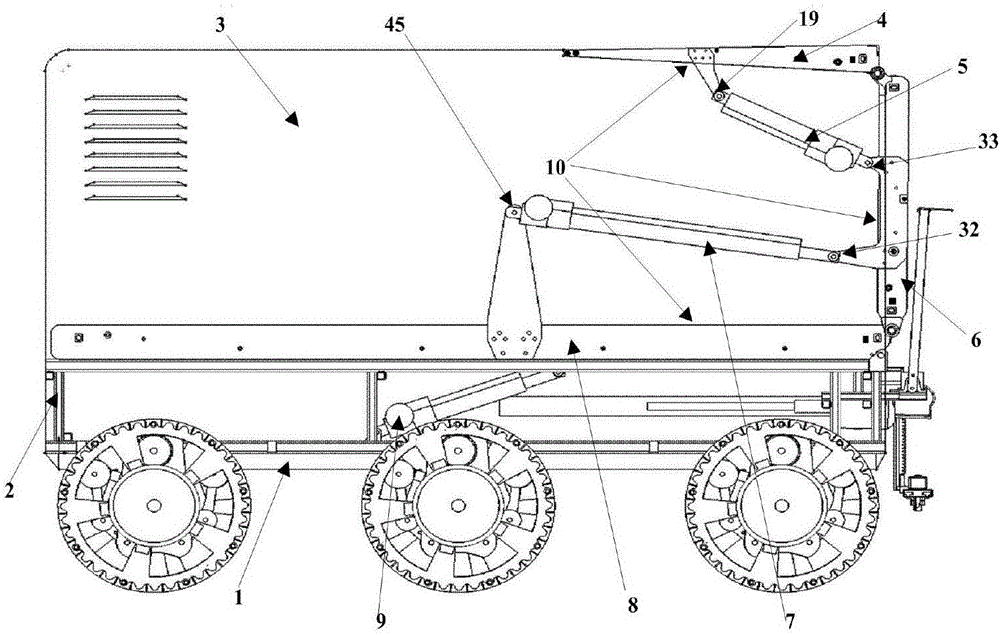

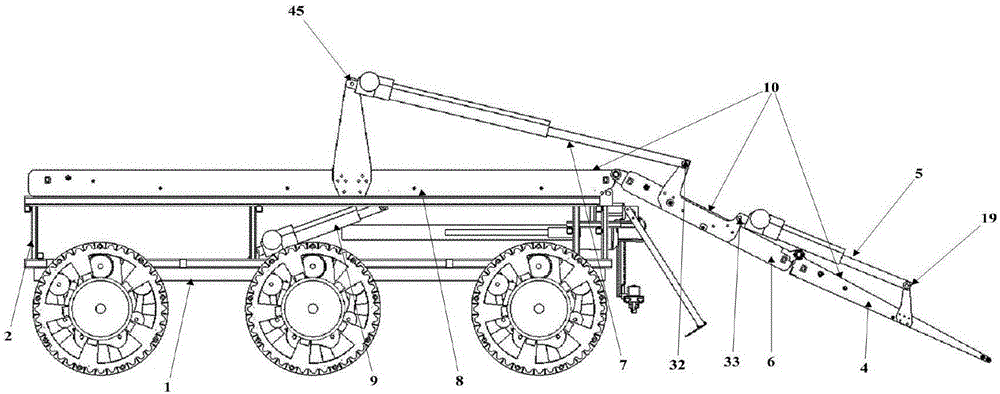

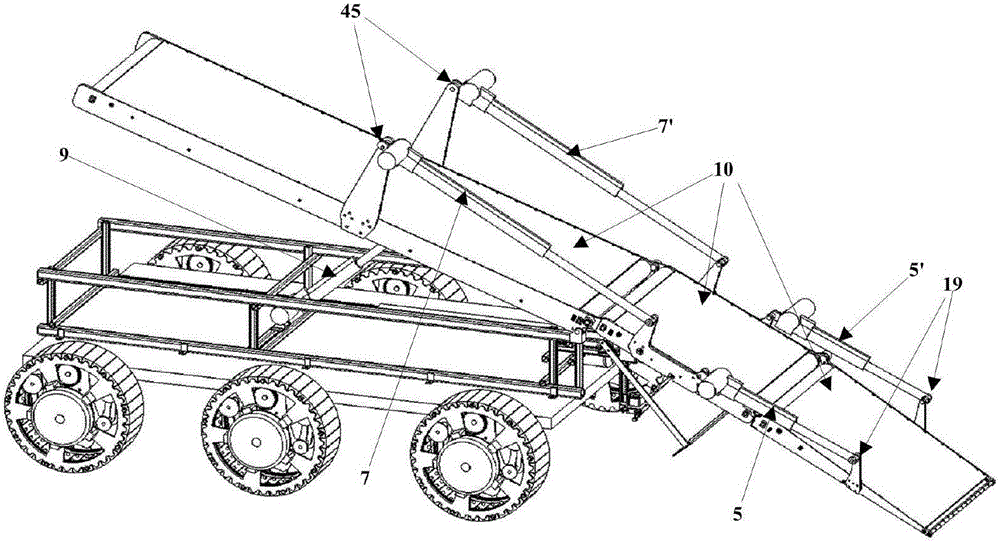

Robot rescue system used in complicated environment

ActiveCN104354159ACompact structureReduce weightProgramme-controlled manipulatorVehicle frameEngineering

The invention relates to a robot rescue system used in a complicated environment. The robot rescue system comprises a personnel placement device (8), an intermediate transitional conveying device (6), a shovel-shaped picking device (4), an obstacle removing device and a multifunctional execution arm, wherein the personnel placement device (8), the intermediate transitional conveying device (6), the shovel-shaped picking device (4), the obstacle removing device and the multifunctional execution arm are arranged on a robot frame (2); the multifunctional execution arm comprises an arm main body fixedly connected with the robot frame (2) and an execution tail end (113) arranged at the tail end of the arm main body; each of the personnel placement device (8), the intermediate transitional conveying device (6) and the shovel-shaped picking device (4) is provided with a conveying belt (11) which is driven by an electric roller, can move in two directions and is used for transporting and moving wounded personnel. Obstacles around the wounded personnel and accessories on the body of the wounded personnel can be removed under the complicated and severe environment, the wounded personnel can be pulled to be away from the dangerous environment, and the trapped and critical wounded personnel can be transported and moved.

Owner:SANITARY EQUIP INST ACAD OF MILITARY MEDICAL SCI PLA

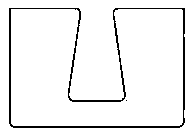

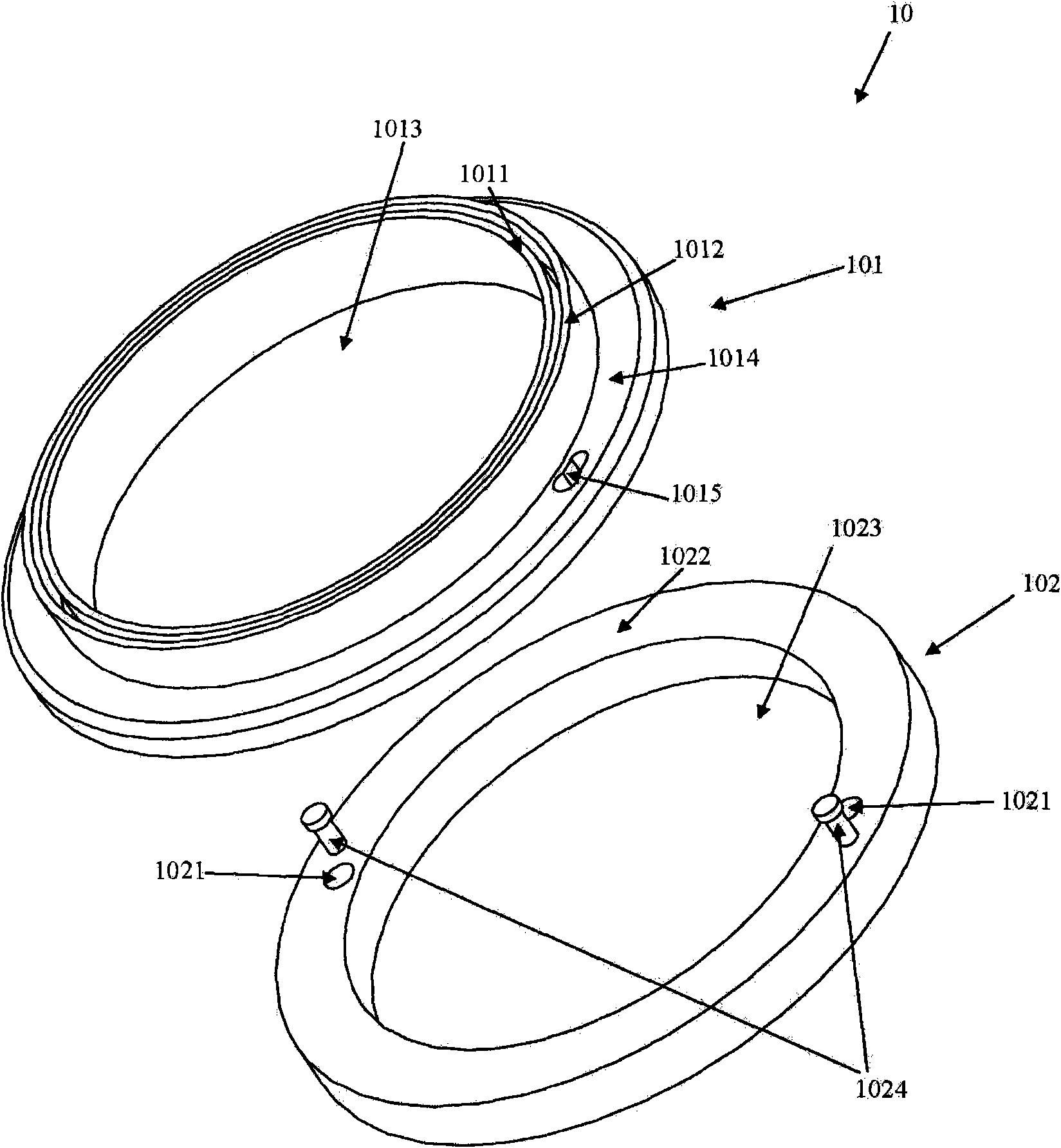

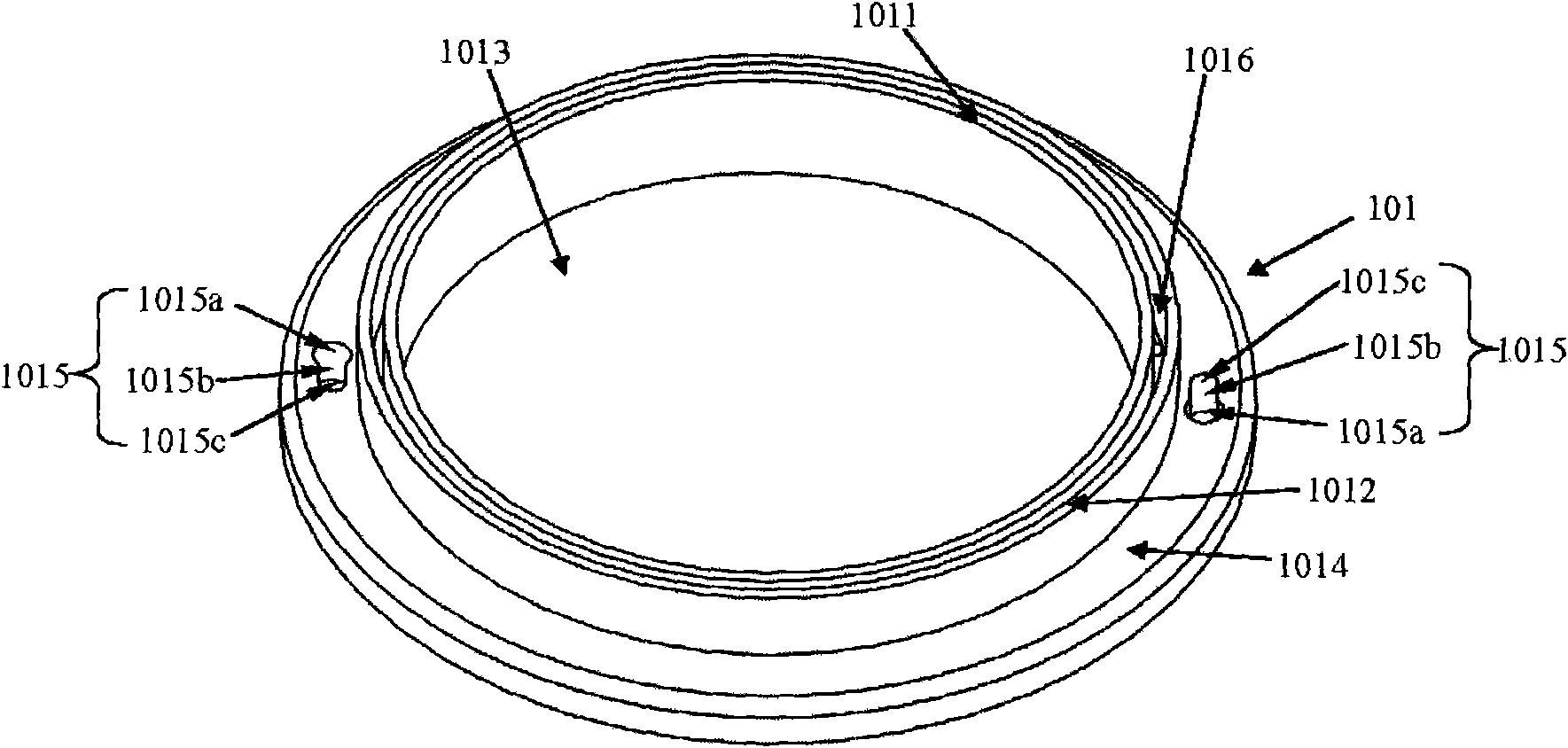

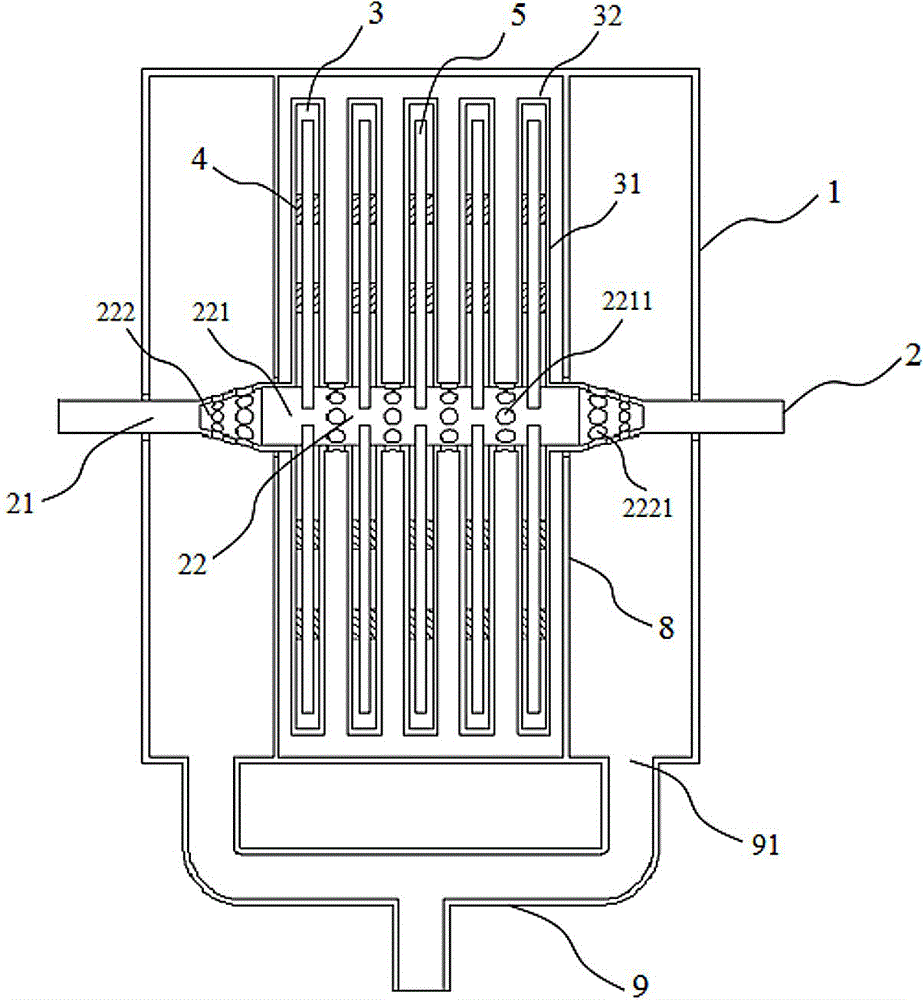

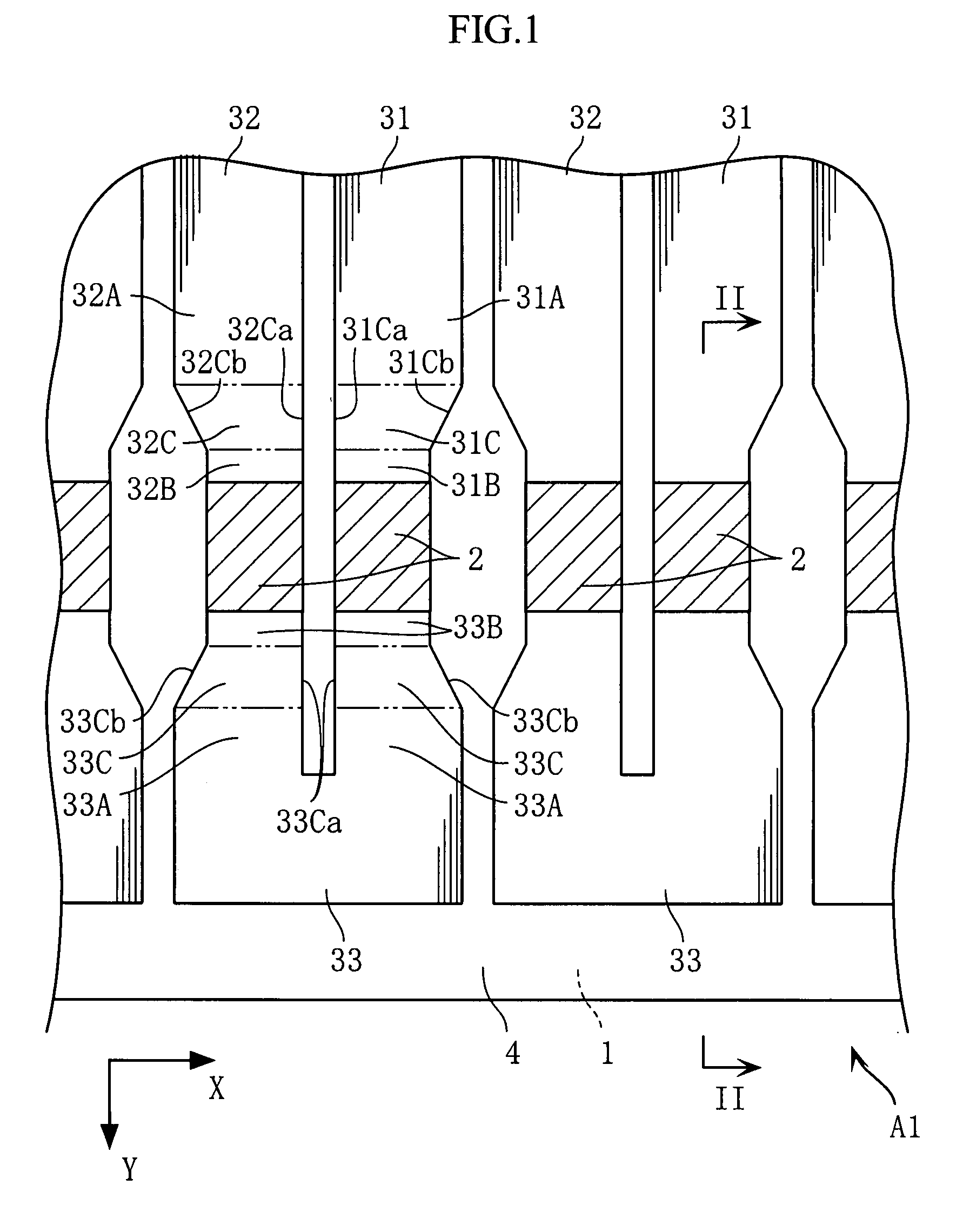

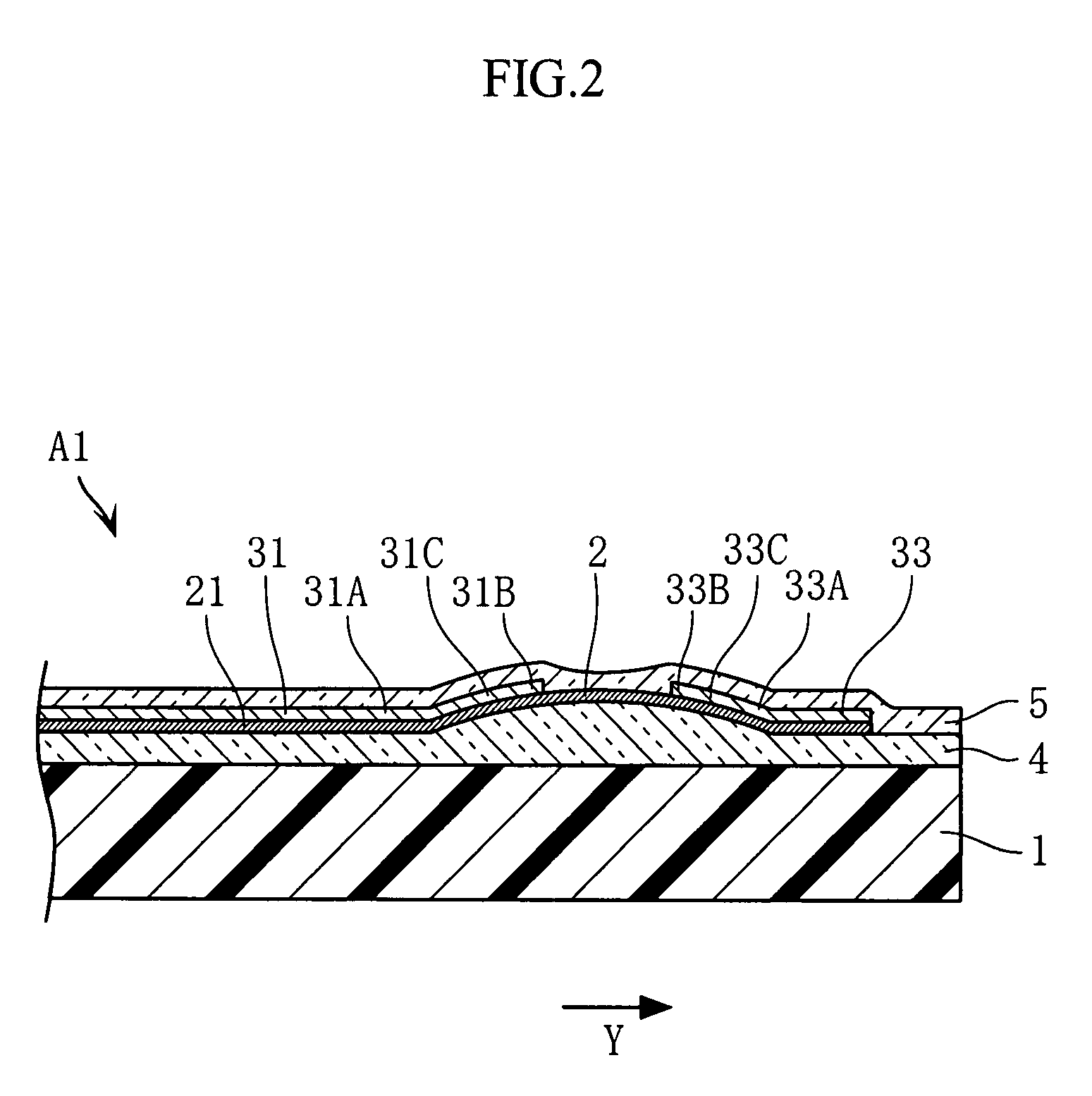

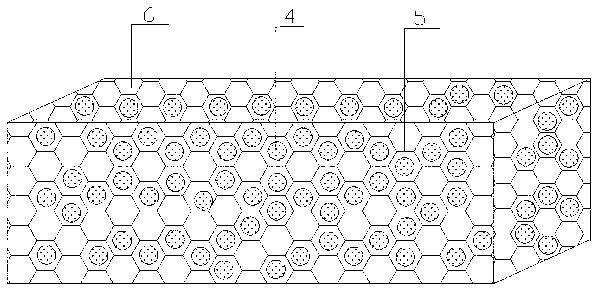

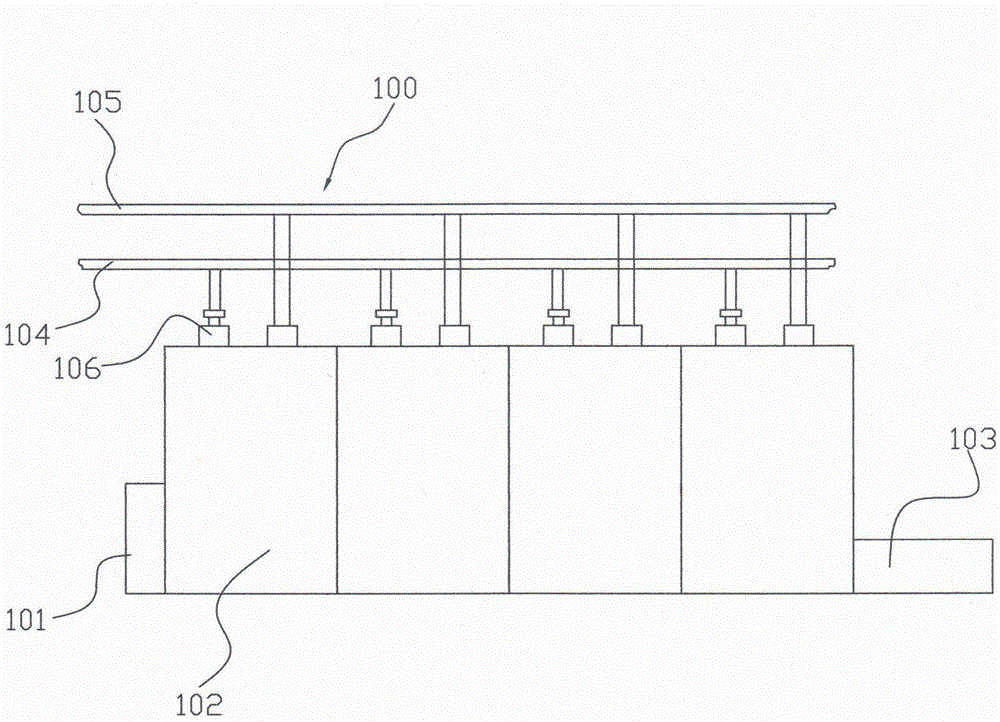

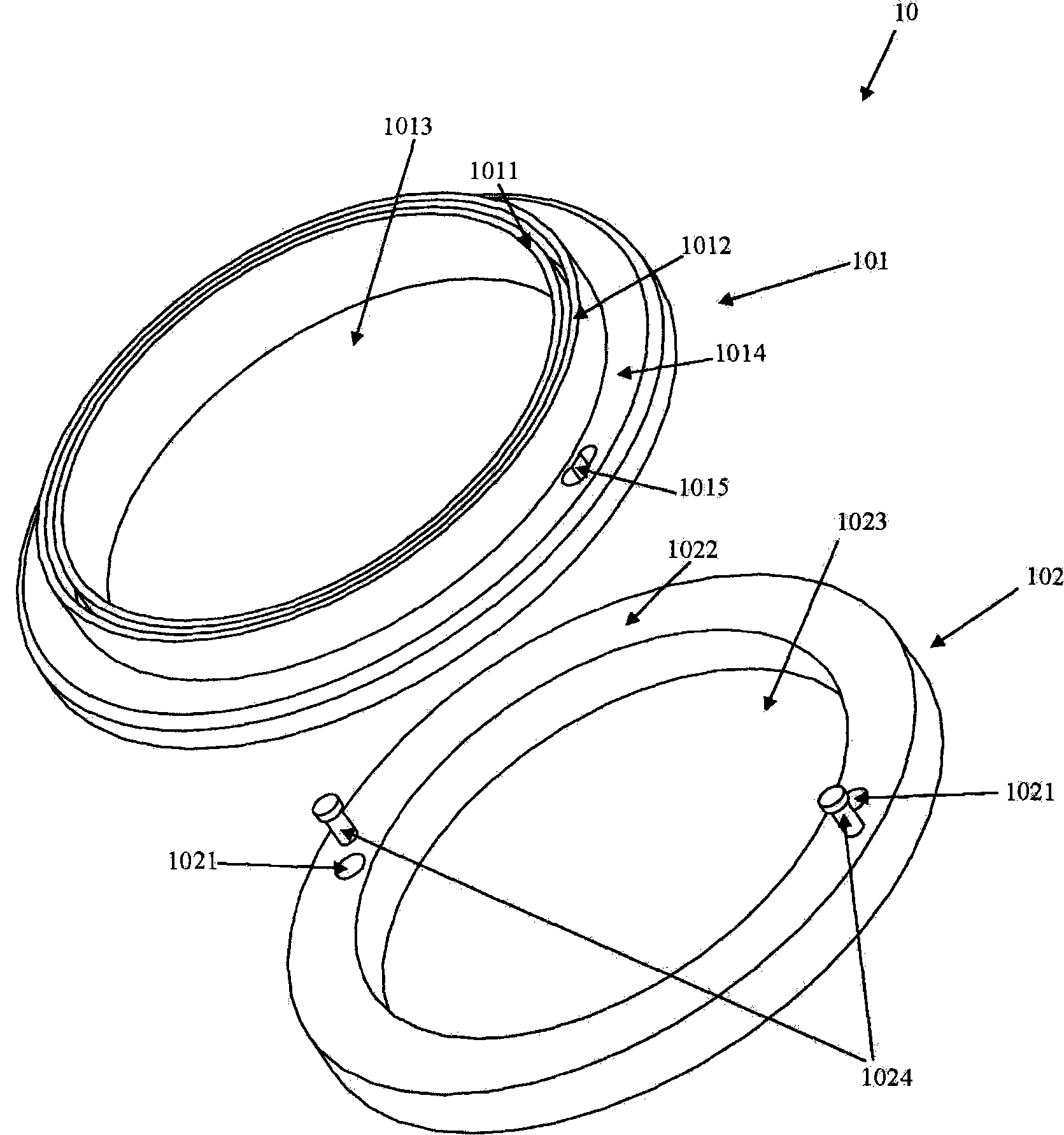

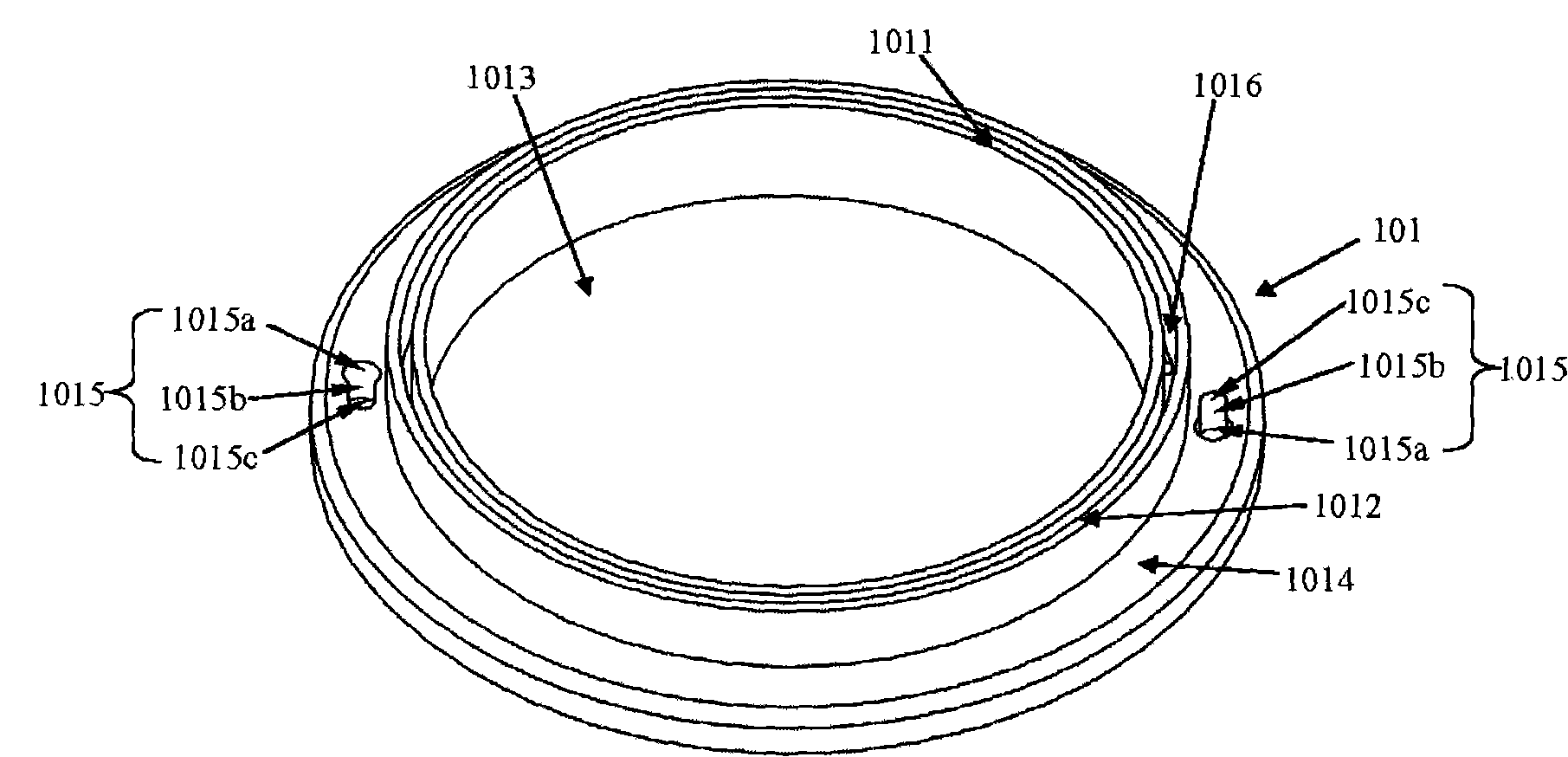

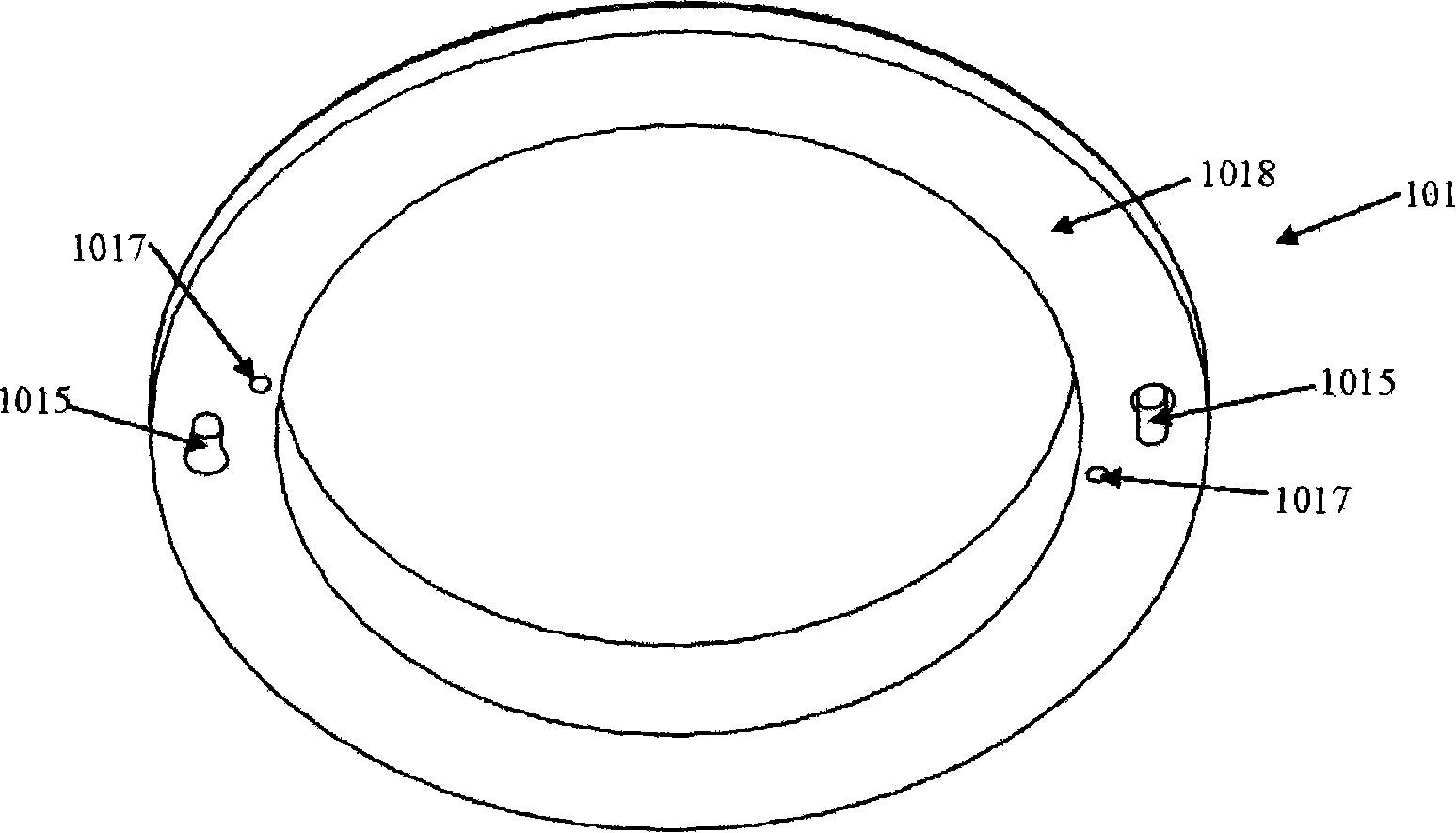

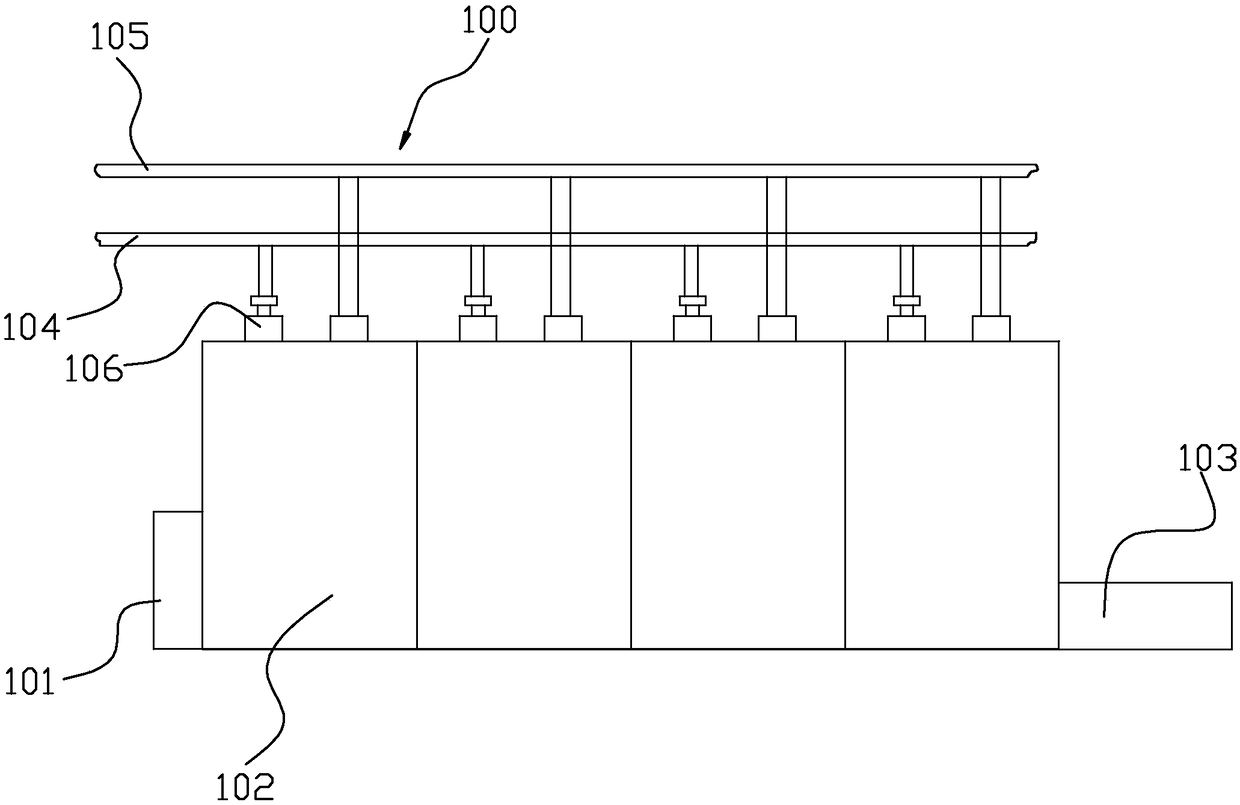

Wafer fixing device and wafer fixing method

InactiveCN101577240AImprove flatness reliabilityImprove convenienceSemiconductor/solid-state device manufacturingEngineeringVacuum state

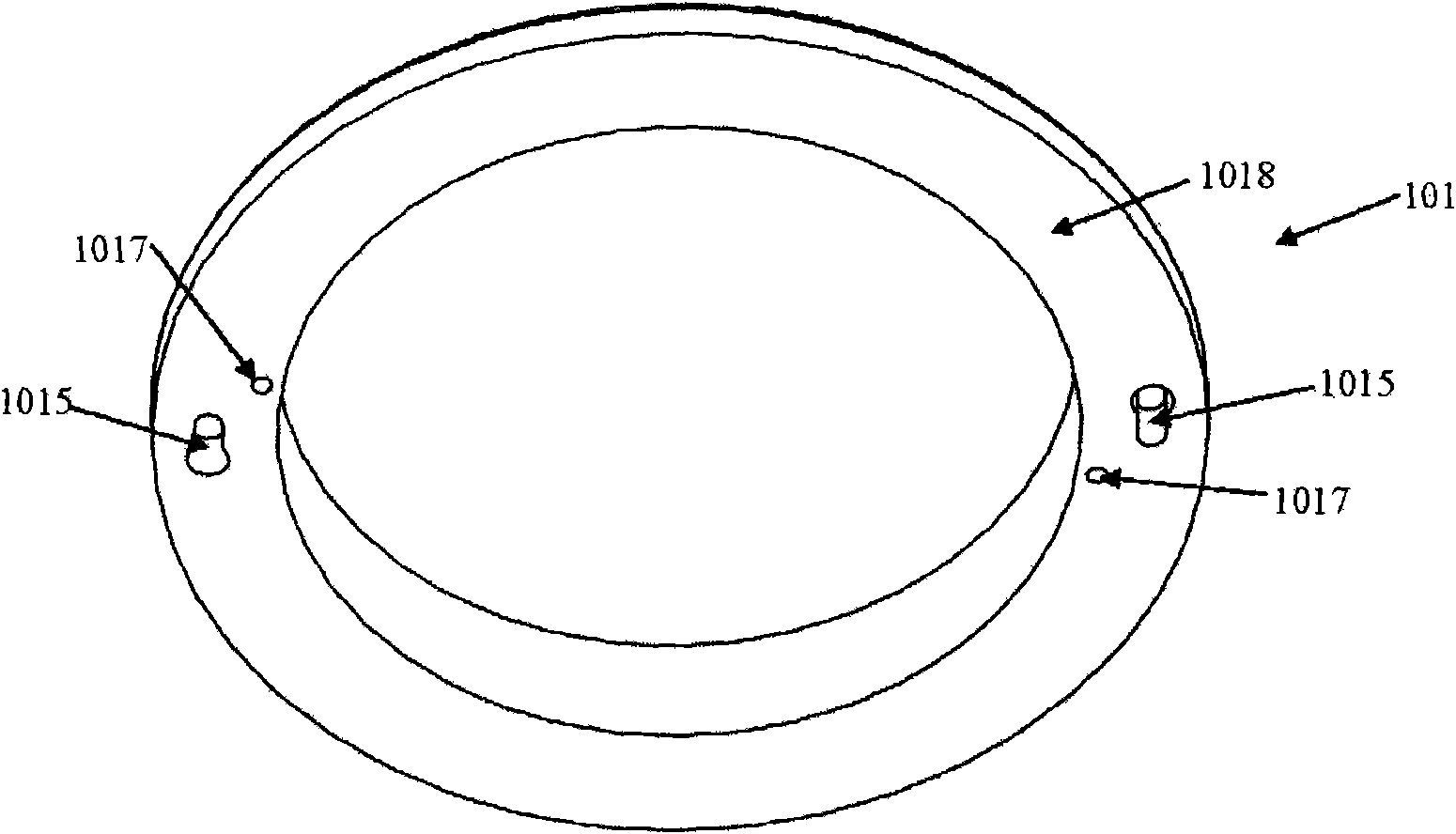

The invention discloses a wafer fixing device and a wafer fixing method, which are used for solving the problems of twisted crystal grain arrangement, poor wafer flatness and poor space usage rate in the prior art. The wafer fixing device comprises a vacuum source, an adsorption device and a wafer fixing ring, wherein a first through hole is formed in the adsorption device, and the first through hole is connected to the vacuum source; the wafer fixing ring is arranged on the adsorption device and is fixed on the adsorption device through a clamping device; and the wafer fixing ring comprises an inner ring, an outer ring and an annular base, wherein the inner ring and the outer ring are formed on the annular base, an adsorption space is formed between the inner ring and the outer ring, and the annular base comprises a second through hole which is used for connecting the first through hole and the adsorption space. The wafer fixing method comprises the following steps: preparing the adsorption device; putting the wafer fixing ring on the adsorption device, and then, clamping the wafer fixing ring and the adsorption device through the clamping device; forming a vacuum state in the wafer fixing ring and the adsorption device; and putting a blue film pasted with a wafer on the wafer fixing ring.

Owner:MICROELECTRONICS TECH INC

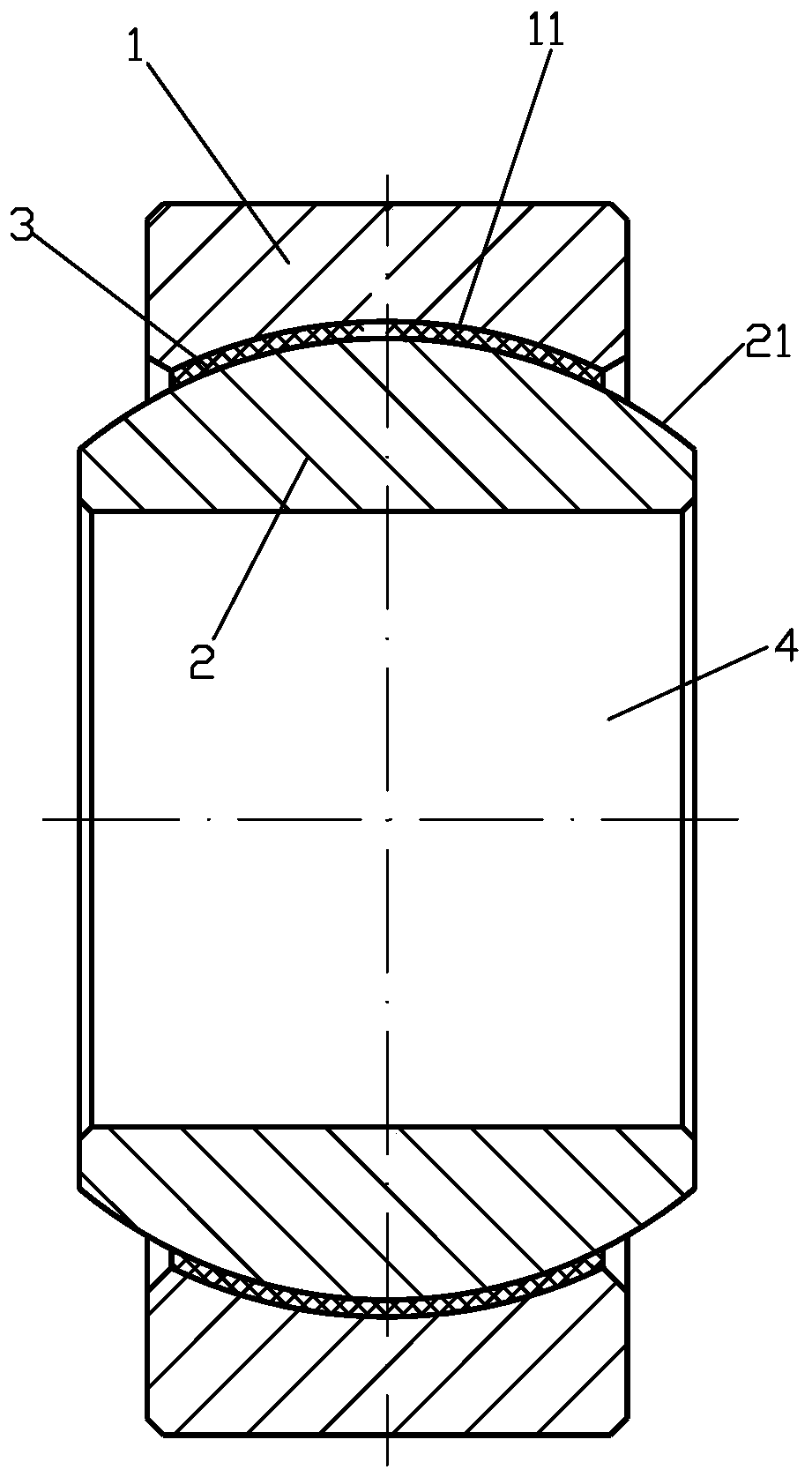

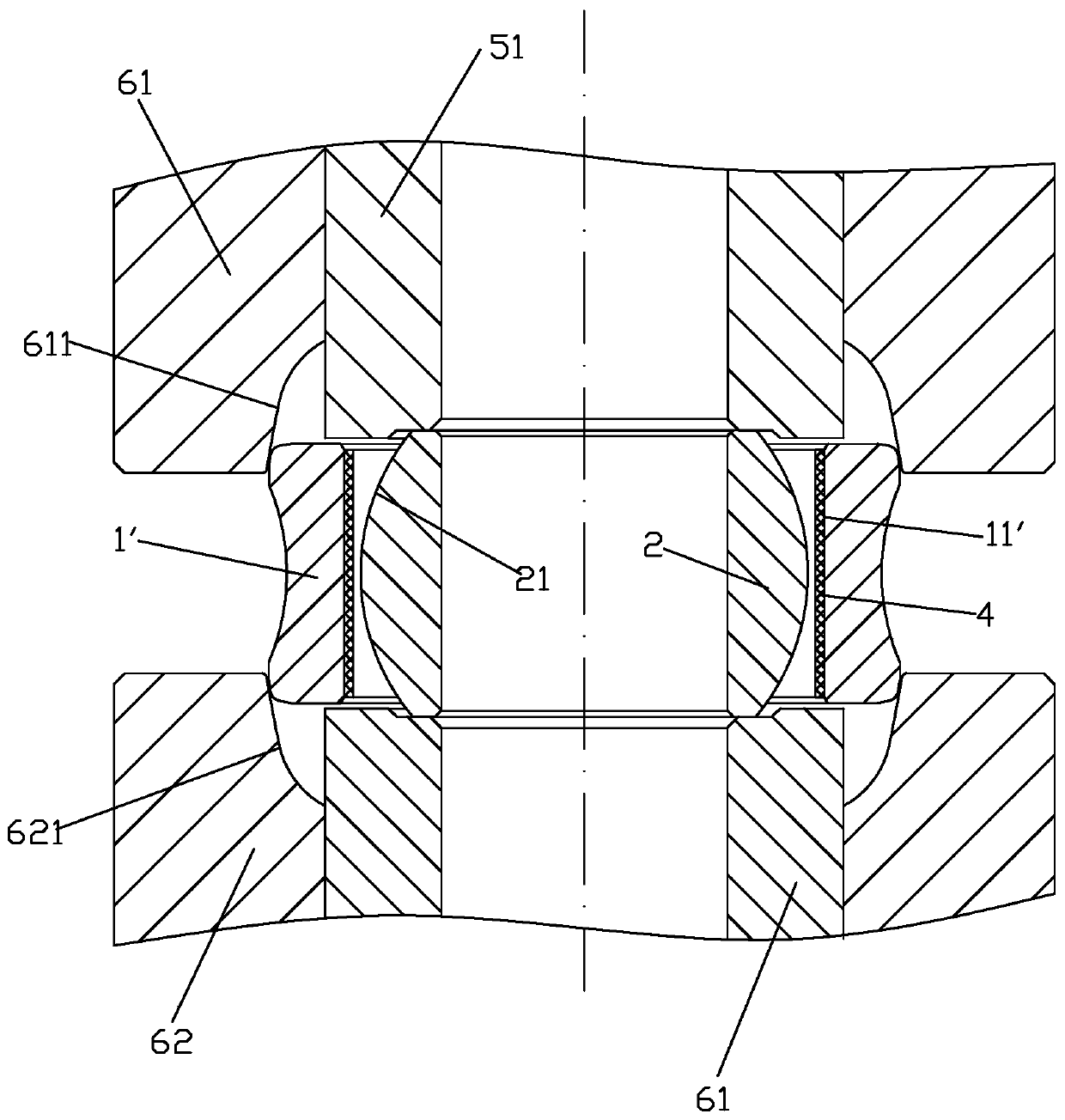

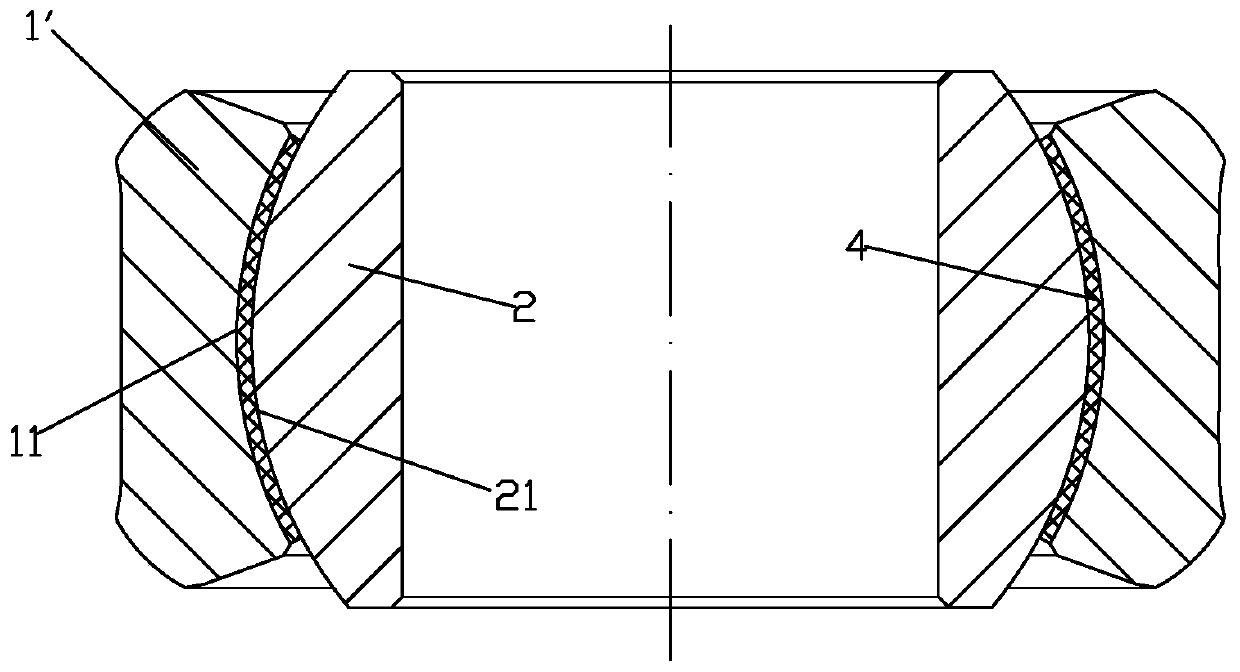

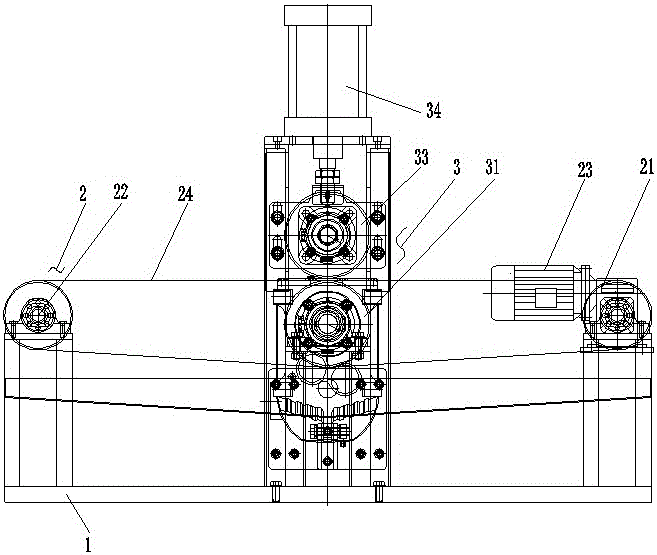

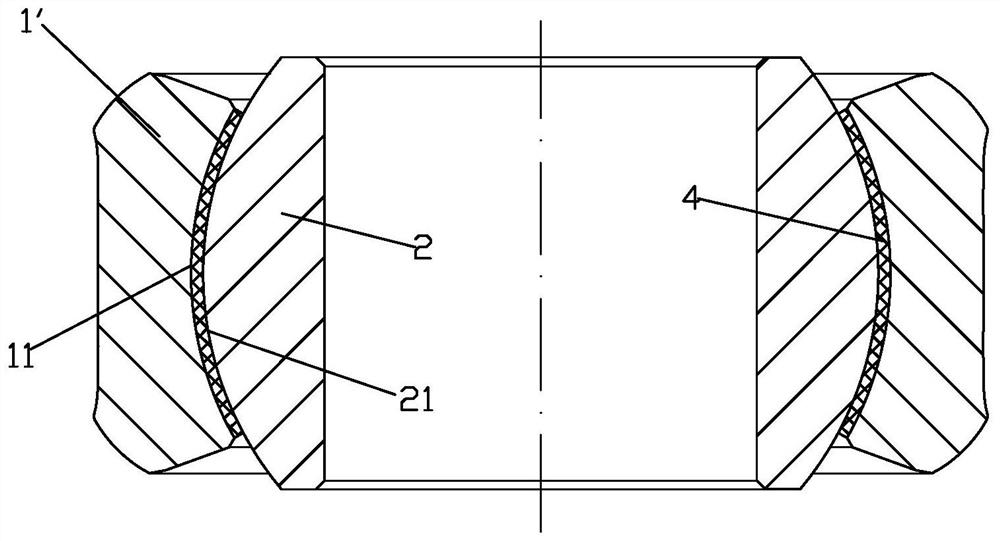

Manufacturing method of molding type self-lubricating knuckle bearing

ActiveCN110131307AOval smallEliminate gapsBearing componentsSliding contact bearingsDeformation effectEllipse

Owner:FUJIAN LONGXI BEARING (GROUP) CO LTD

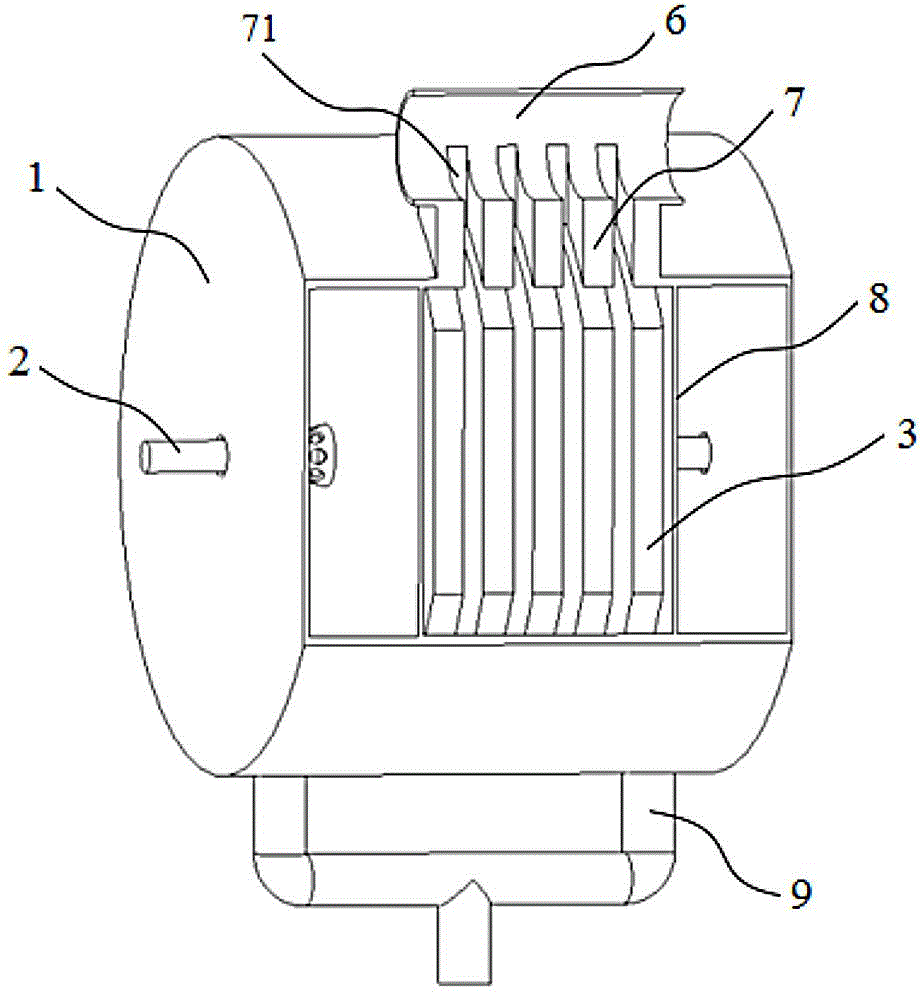

Bladeless turbine engine

InactiveCN104895617AImprove conversion efficiencyReduce lossesEngine componentsNon-positive displacement enginesSpray nozzleEngineering

The invention discloses a bladeless turbine engine. The bladeless turbine engine comprises a cylinder, a rotating shaft, a plurality of empty chamber disk bodies, a plurality of tie bars, a plurality of heat pipes, a steam inlet pipe, a spray pipe group, a separation plate and a steam exhaust pipe. A certain pressure and temperature of viscous fluid spirally and centripetally flows in the cylinder from outside to inside along the circumferential direction after being expanded and accelerated through a spray nozzle and the plurality of empty chamber disk bodies and the rotating shaft are driven to rotate and do work together under the action of shear force of the fluid in a boundary layer. The plurality of different diameters of circular ring tie bars are arranged in every empty chamber disk body for reinforcement, a filled gas cooling medium is used for absorbing the heat dissipation capacity of every empty chamber disk body, and the heat is transferred into an inner chamber of a hollow drum of the rotating shaft from an inner chamber of every empty chamber disk body through the heat pipes to be absorbed through the low temperature exhaust steam eventually. According to the bladeless turbine engine, the energy conversion efficiency is high, the structure is firm and durable, the tensile strength and distortion strength are high, the deformation caused by overhearing is effectively prevented, the unit power is large, and the future application process of the bladeless turbine engine is greatly promoted.

Owner:JIMEI UNIV

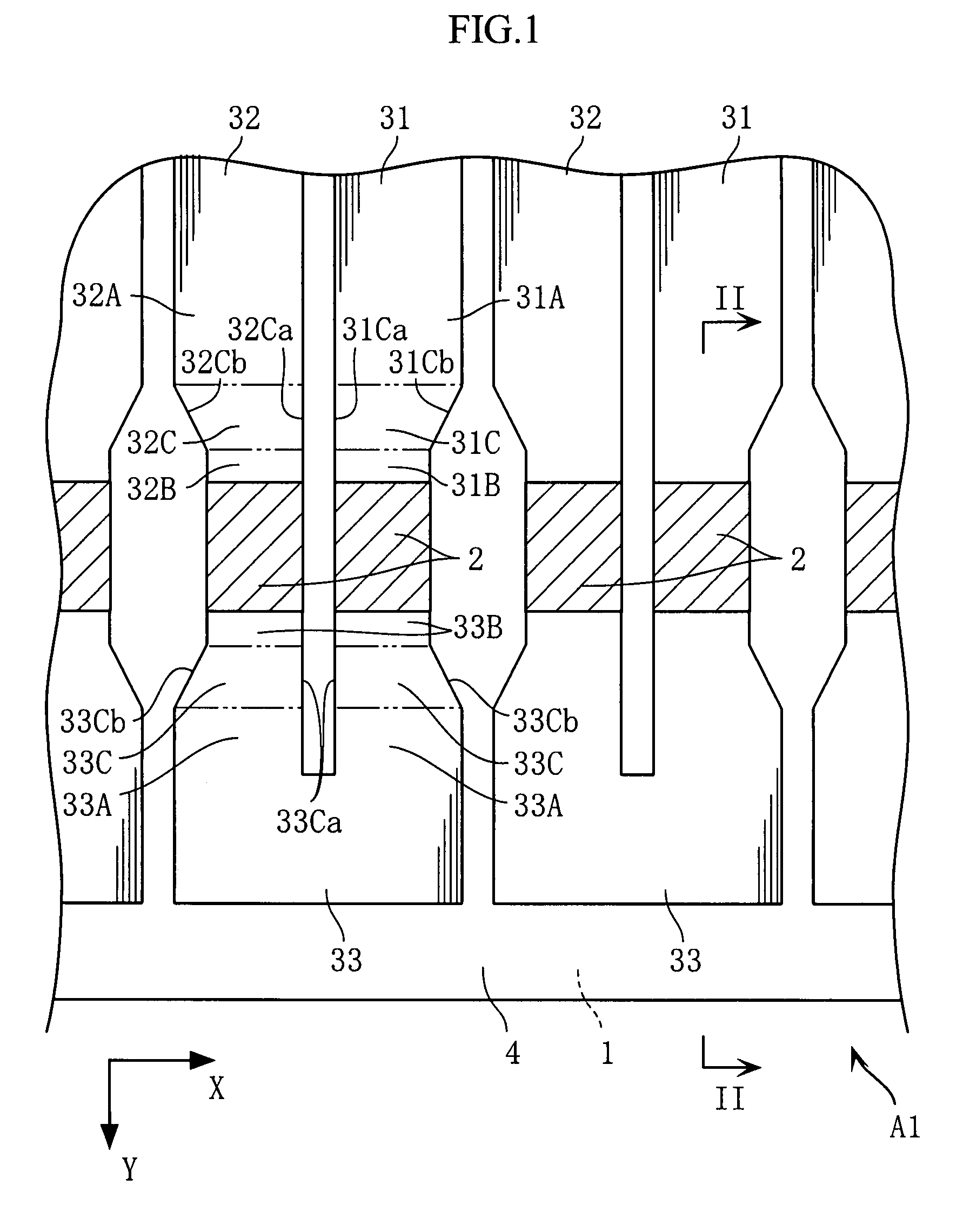

Thermal Print Head

Owner:ROHM CO LTD

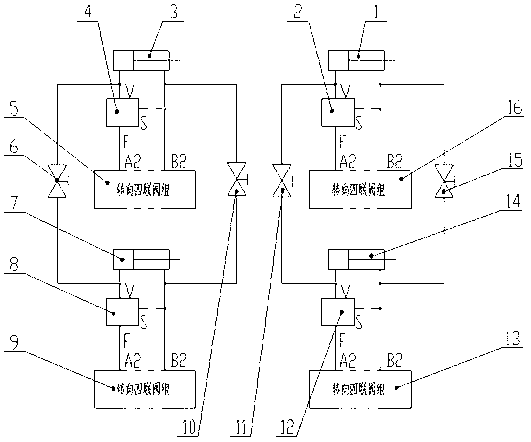

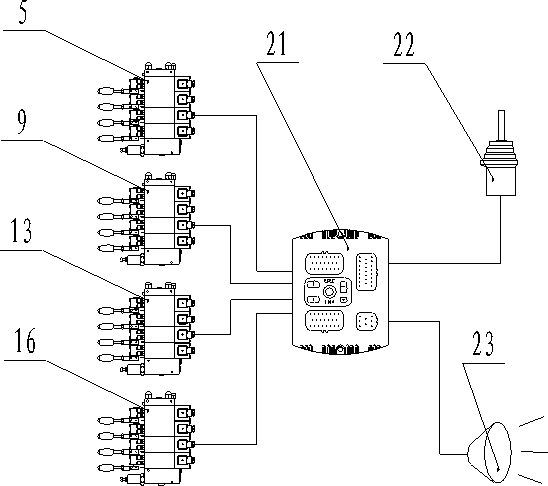

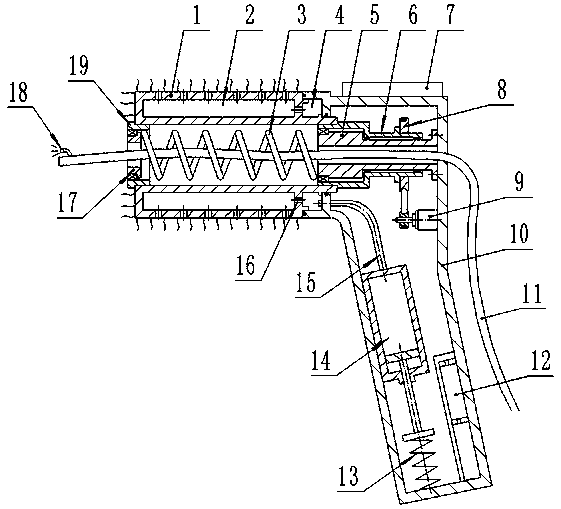

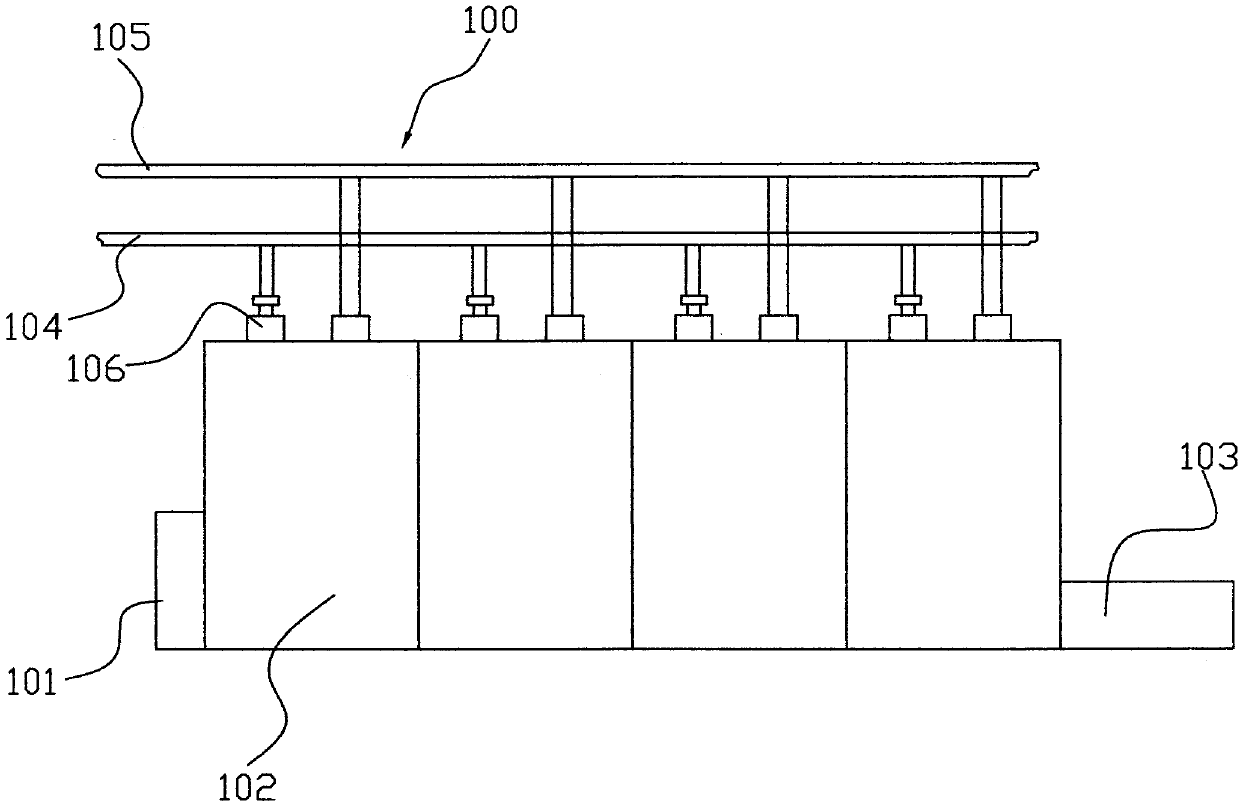

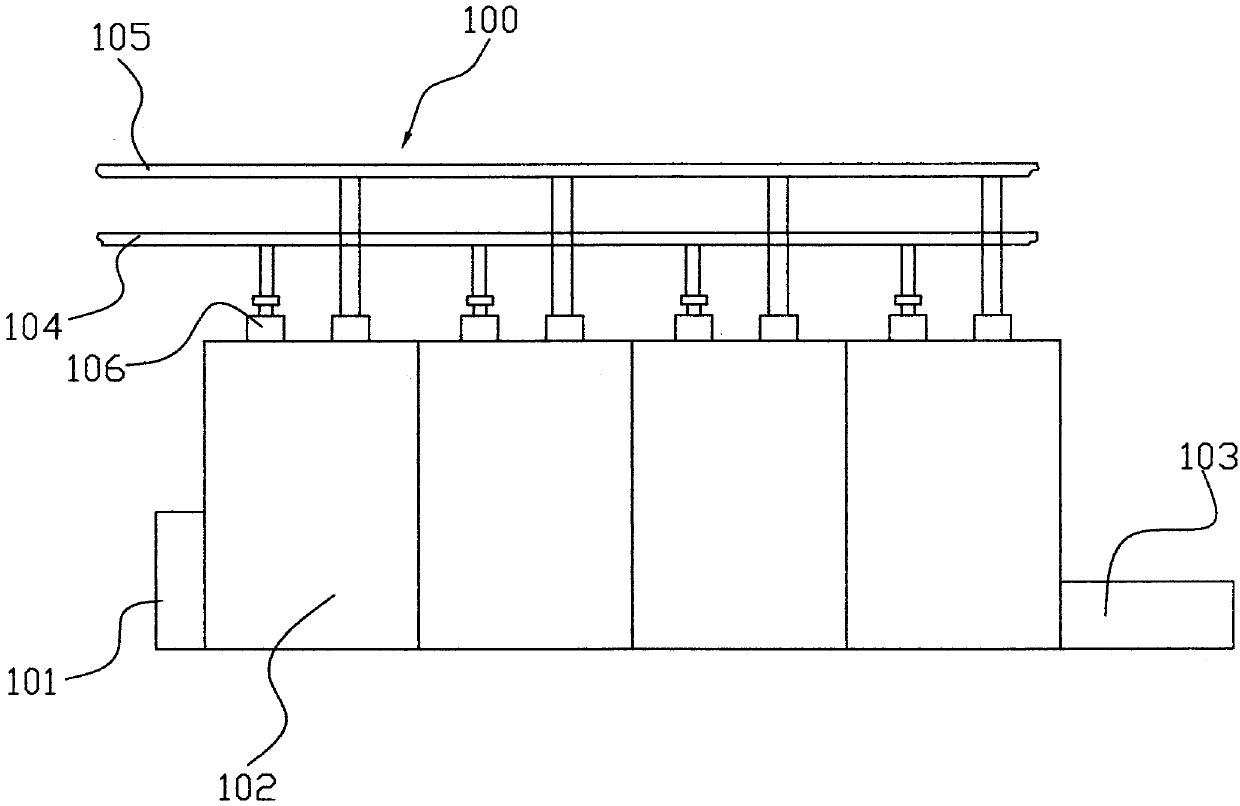

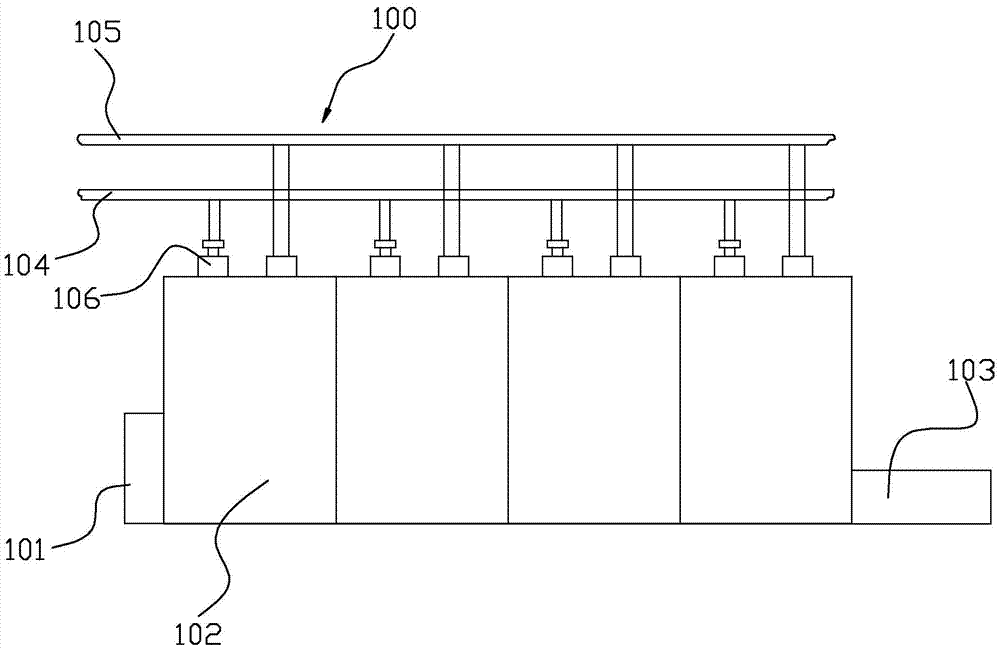

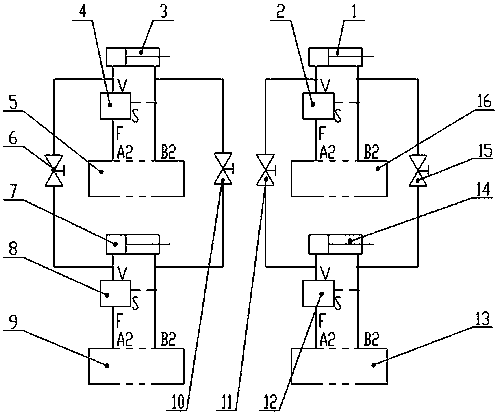

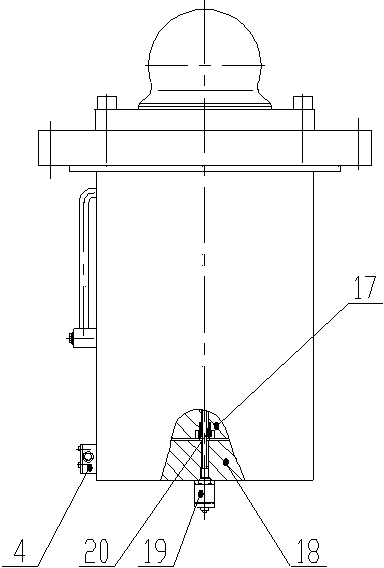

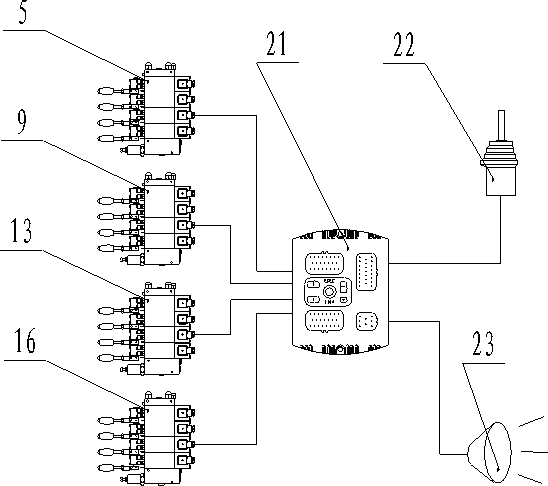

Hydraulic jacking system of transporting girder vehicle

ActiveCN102700448ANot distortedNo tiltVehicle with parallel load movementProportional controlElectrical control

The invention belongs to hydraulic jacking systems, and relates to a hydraulic jacking system of a transporting girder vehicle, which comprises four hydraulic jacking cylinders loaded with displacement sensors, four electrical control proportioning valves, four ball valves, an operating handle, a controller and a warner, wherein the four hydraulic jacking cylinders are divided into two groups, that is, a front group and a rear group; rod chambers of the two hydraulic jacking cylinders in each group are connected by a hydraulic pipeline; one of the ball valves is arranged in the middle of the pipeline; likewise, rodless chambers of the two hydraulic jacking cylinders in the group are connected; when the four ball valves in the front group and the rear group are closed, the hydraulic jacking cylinders form four points for supporting a box girder; when the two ball valves in one group are closed, and the two ball valves in the other group are opened, the hydraulic jacking cylinders form four points acting on the box girder and three points for supporting the box girder so as to ensure that the box girder is not twisted during the lifting and transporting processes; during the process of the lifting of the box girder, the displacement sensors monitor the lifting heights of the cylinders in a real-time manner; and when the lifting speed of the some cylinder is too high, the controller gives out a command to the control valve to a proportional control valve to automatically adjust the lifting speed of the cylinders and further ensure that the box girder is not inclined during the process of lifting.

Owner:徐州徐工能源装备有限公司

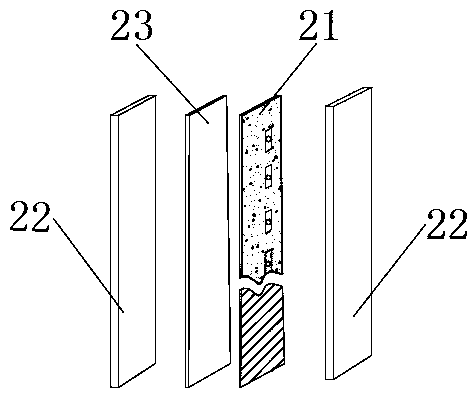

Photocatalyst nano bamboo-wood composite plate

InactiveCN102888964AHigh tensile strengthLow shrinkageCovering/liningsWood layered productsSolid woodFiber

The invention discloses a photocatalyst nano bamboo-wood composite plate, relating to the technical field of building decoration. The composite plate comprises a decoration layer, a photocatalyst nano bamboo filament layer and a solid wood layer, wherein the solid wood layer is the bottommost layer, the photocatalyst nano bamboo filament layer is arranged on the solid wood layer, and the decoration layer is the uppermost layer. The photocatalyst nano bamboo filament layer contains bamboo filaments and nano titanium dioxide; and in the process of forming, the bamboo filaments are sequenced arbitrarily in a mold, and then the nano titanium dioxide is mixed in the bamboo filaments, in such a way, the middle of a formed plate has holes. The composite plate disclosed by the invention has the beneficial effects that because a bamboo high-fiber plate is adopted, a floor is wear-resistant, pressure-proof, moisture-proof, fireproof, high in tensile strength and low in shrinkage rate, and does not crack, distort and deform after being laid; the photocatalyst nano titanium dioxide generates a strong catalytic degradation function under the action of light; and because the bamboo filament layer of the plate is provided with holes, the contact area between the air and the material is increased, so that the photocatalytic efficiency is improved.

Owner:栾清杨

Thermal print head

Owner:ROHM CO LTD

Oral cleaning medical care device

The invention discloses an oral cleaning medical care device and belongs to a medical device. The oral cleaning medical care device has good visibility, is easy to operate and has high safety. The oral cleaning medical care device comprises a handle, a brush roller and a motor. A support shaft (5), the motor (9) and a syringe (14) are arranged in the handle (10). A shaft sleeve (6) is mounted on the support shaft (5). The motor (9) drives the shaft sleeve (6) to rotate. A piston rod of the syringe (14) is tightened by a spring (13). The brush roller (1) has a jacket-like structure. The jacketis provided with water outlet holes. The right end of the jacket is provided with a ring groove. The ring groove is communicated with a water chamber (2). The brush roller (1) is fixed to the supportshaft (5). The ring groove is blocked through the handle (10) so that a water injection chamber (4) is formed. The water injection chamber (4) is communicated with the syringe (14) through a water passage (15). The oral cleaning medical care device has a simple structure, is easy to operate, has good cleaning effects and is used for oral cleaning medical care.

Owner:王灵

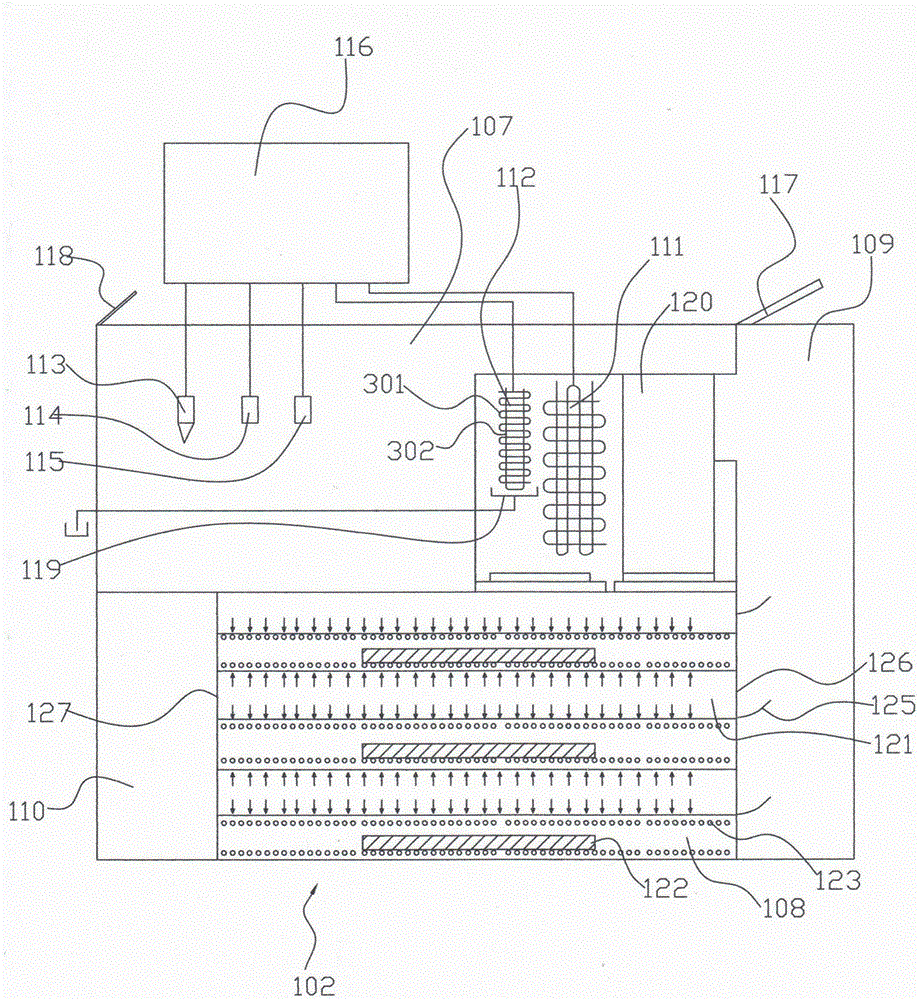

Humidifying dryer used for drying lamellar soft products and capable of easily adjusting temperature and humidity

The invention discloses a humidity-adjusting dryer for drying layered soft products, which is easy to adjust temperature and humidity. It is used for drying layered soft products. room, transmission room, air inlet duct and air return duct connected with the adjustment room and transmission room, the adjustment room has a heating device and a blower, and the adjustment room is also equipped with a cooling and dehumidification device and a temperature detector that cooperate with each other , a humidity detector, a spray gun for increasing the humidity of the hot air in the conditioning unit, and a computer-controlled real-time controller for controlling the heating device, refrigeration and dehumidification device, temperature detector, humidity detector and spray gun.

Owner:刘新梅

Sculpture Reproduction and Enlargement Method

InactiveCN104015535BSolve difficult crafting puzzlesConsistent proportionModel makingEngraving3d printer

The invention belongs to the technical field of statue engraving, and relates to an engraving method, in particular to a method for duplicating and enlarging a sculpture. The method overcomes the defects in the prior art, and saves time and labor, the enlarged sculpture is not distorted, and the method can be used for producing large products. According to the technical scheme, a model of a large sculpture is scanned in a three-dimension scanner to form an electronic model, the model is sliced to be processed and then is processed through a flat carving machine, and processed slices are bonded and then ground and corrected to be molded. Compared with a traditional sculpture enlarging method, the large sculpture is sliced to be processed, and then the processed slices are bonded, so that a manufactured sculpture is larger, the size of the sculpture is far beyond the largest range of a 3D printer and a circular carving machine, and the problem that a large sculpture is hard to manufacture is solved.

Owner:SHANXI BIMU MOER BUILDING TECH CO LTD

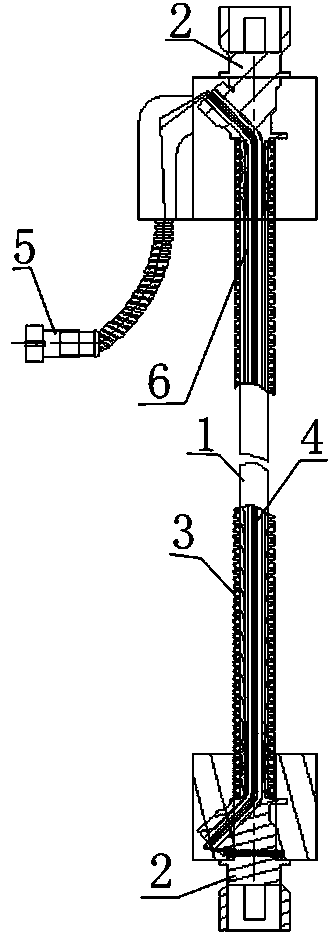

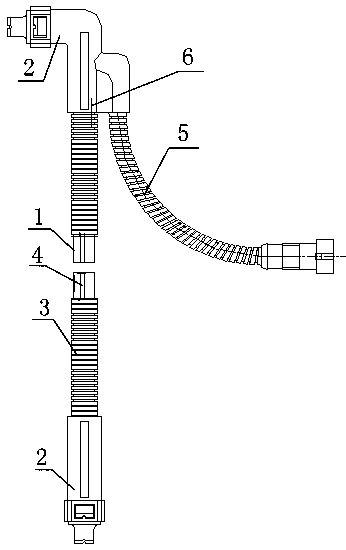

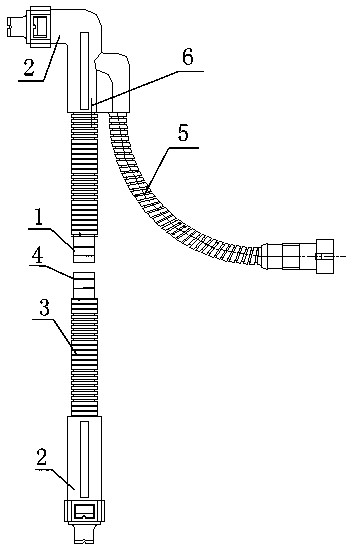

Urea heating liquid return pipe

InactiveCN107687361ANo deformationNot distortedExhaust apparatusSilencing apparatusCouplingTransducer

The invention relates to a urea heating liquid return pipe. Rapid inserting connectors are arranged at the two ends of a urea liquid return pipe body correspondingly. A corrugated pipe is arranged outside the urea liquid return pipe body. A heating wire or a heating belt is arranged in the urea liquid return pipe body and is arranged at the center position through the rapid inserting connectors atthe two ends in the urea liquid return pipe body, and a lead-out plug arranged on the side wall of one rapid inserting connector is used for wire connection. A temperature sensor is further arrangedin the urea liquid return pipe body, and the lead-out plug is used for wire connection. The heating wire or the heating belt in the urea liquid return pipe body is cured in the rapid inserting connectors at the two ends. The lead-out plug is also cured on the side wall of one rapid inserting connector. The heating wire or the heating belt conducts heating in the urea liquid return pipe body, a heating element is planted in a middle part in the pipe, plastics at the two ends are located at the center position in the pipe, and when the urea solution enters a pipe body, the urea solution flows ata constant speed, the purpose of constant-speed heating is achieved; and it is guaranteed that heat conductive heating power losses are avoided.

Owner:湖北拓威汽车尾气系统有限公司

Wafer fixing device and wafer fixing method

InactiveCN101577240BImprove flatness reliabilityImprove convenienceSemiconductor/solid-state device manufacturingWaferEngineering

The invention discloses a wafer fixing device and a wafer fixing method, which are used for solving the problems of twisted crystal grain arrangement, poor wafer flatness and poor space usage rate in the prior art. The wafer fixing device comprises a vacuum source, an adsorption device and a wafer fixing ring, wherein a first through hole is formed in the adsorption device, and the first through hole is connected to the vacuum source; the wafer fixing ring is arranged on the adsorption device and is fixed on the adsorption device through a clamping device; and the wafer fixing ring comprises an inner ring, an outer ring and an annular base, wherein the inner ring and the outer ring are formed on the annular base, an adsorption space is formed between the inner ring and the outer ring, andthe annular base comprises a second through hole which is used for connecting the first through hole and the adsorption space. The wafer fixing method comprises the following steps: preparing the adsorption device; putting the wafer fixing ring on the adsorption device, and then, clamping the wafer fixing ring and the adsorption device through the clamping device; forming a vacuum state in the wafer fixing ring and the adsorption device; and putting a blue film pasted with a wafer on the wafer fixing ring.

Owner:MPI CORP

Sealed urea heating pipe

InactiveCN107687360ANo deformationNot distortedExhaust apparatusSilencing apparatusCouplingClean appearance

The invention relates to a sealed urea heating pipe. Quick inserting joints are arranged at the two ends of a urea liquid return pipe correspondingly. A corrugated pipe is arranged at the exterior ofthe urea liquid return pipe. The urea liquid return pipe is externally provided with a heating wire or a heating band which covers the urea liquid return pipe and cures the quick inserting joints at the two ends. An inserting joint connecting wire is led out through the side wall arranged on each quick inserting joint. The quick inserting joints and the urea liquid return pipe are subjected to one-time plastic sealing and curing. A led inserting joint is further cured on the side wall of the corresponding quick inserting joint, and the led inserting joint and the corresponding quick insertingjoint form a whole. The urea liquid return pipe is internally provided with the heating wire or the heating band which is arranged in the center through the quick inserting joins at the two ends in the urea liquid return pipe. The inserting joint connecting wires are led out through the side walls arranged on the quick inserting joints. The heating wire or the heating band is cured in the quick inserting joins at the two ends in the urea liquid return pipe. According to the sealed urea heating pipe, the whole is formed, beautiful appearance and neatness are achieved, water can never enter theurea pipe, and even if the urea pipe soaked in the water, the water cannot enter the urea pipe, so that it is ensured that the resistance value cannot be increased and high temperature, even an ignition phenomenon, cannot be produced.

Owner:湖北拓威汽车尾气系统有限公司

Composite board

InactiveCN103121314AHigh tensile strengthLow shrinkageSynthetic resin layered productsMetal layered productsPolymer scienceCarbon fibers

The invention relates to the field of boards, in particular to a composite board which comprises a durable layer, a carbon fiber layer, a resin layer, a photocatalyst coating and a base layer. The base layer, the photocatalyst coating, the resin layer, the carbon fiber layer and the durable layer are sequentially arranged from inside to outside. The durable layer is made of non-toughened glass or marble. The base layer is preferably made of aluminum metal materials. The middle of the carbon fiber layer is reinforced by a thin steel mesh.

Owner:DALIAN DEDA TECH DEV

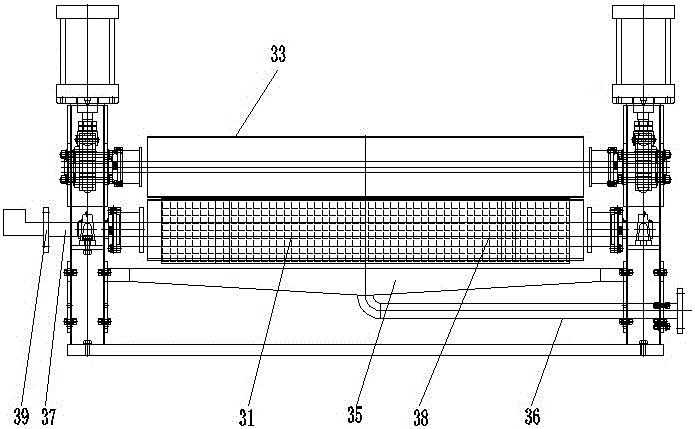

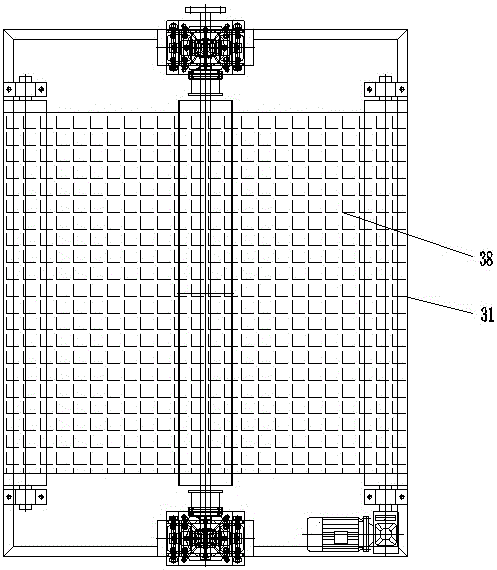

Continuous vacuum dehydration device

InactiveCN106835565ALint freeNot distortedLiquid/gas/vapor removal by suctionVacuum extractionPulp and paper industry

The invention discloses a continuous vacuum dehydration device. The device includes a rack, transportation net-belt assemblies and a dehydration assembly, wherein the transportation net-belt assemblies are arranged at the two sides of the rack and used for transporting materials, and the dehydration assembly is arranged on the rack and used for dehydrating the materials. The dehydration assembly includes a vacuum dehydration roller of which the two ends are connected to the rack, the transportation net-belt assemblies transport the materials to the vacuum dehydration roller, the vacuum dehydration roller conducts vacuum dehydration on the materials, one end of the vacuum dehydration roller is connected with a vacuum extraction device, a plurality of air holes are uniformly formed in the surface of the vacuum dehydration roller, and the vacuum dehydration roller vacuumizes inner space by the vacuum extraction device to discharge moisture of the materials through the air holes. In this way, the continuous vacuum dehydration device can simultaneously conduct dehydration and drying and enable the materials to successively and automatically enter the next process to be processed. After the vacuum dehydration, the surfaces of the materials do not fluff, the materials do not contort and have less damage, the dehydration is continuous, and the dehydration efficiency is relatively high.

Owner:无锡惠山万邦科技有限公司

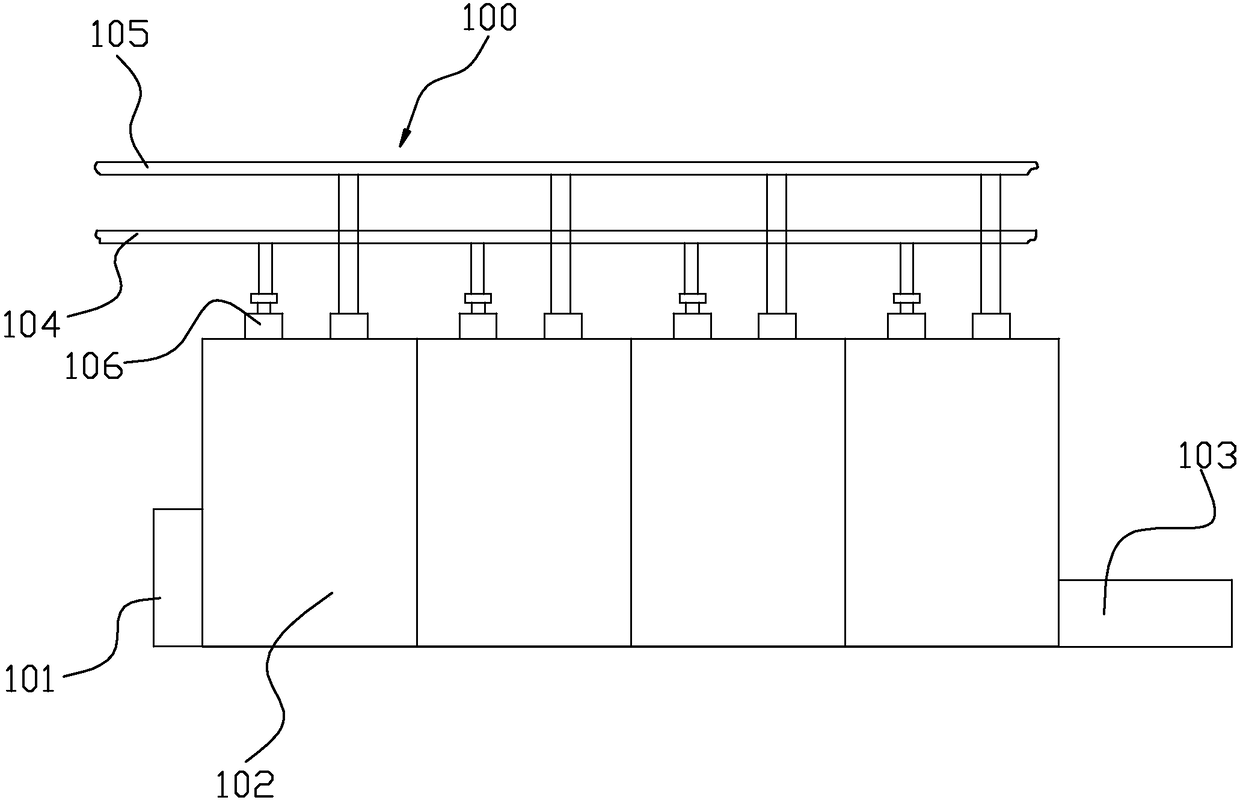

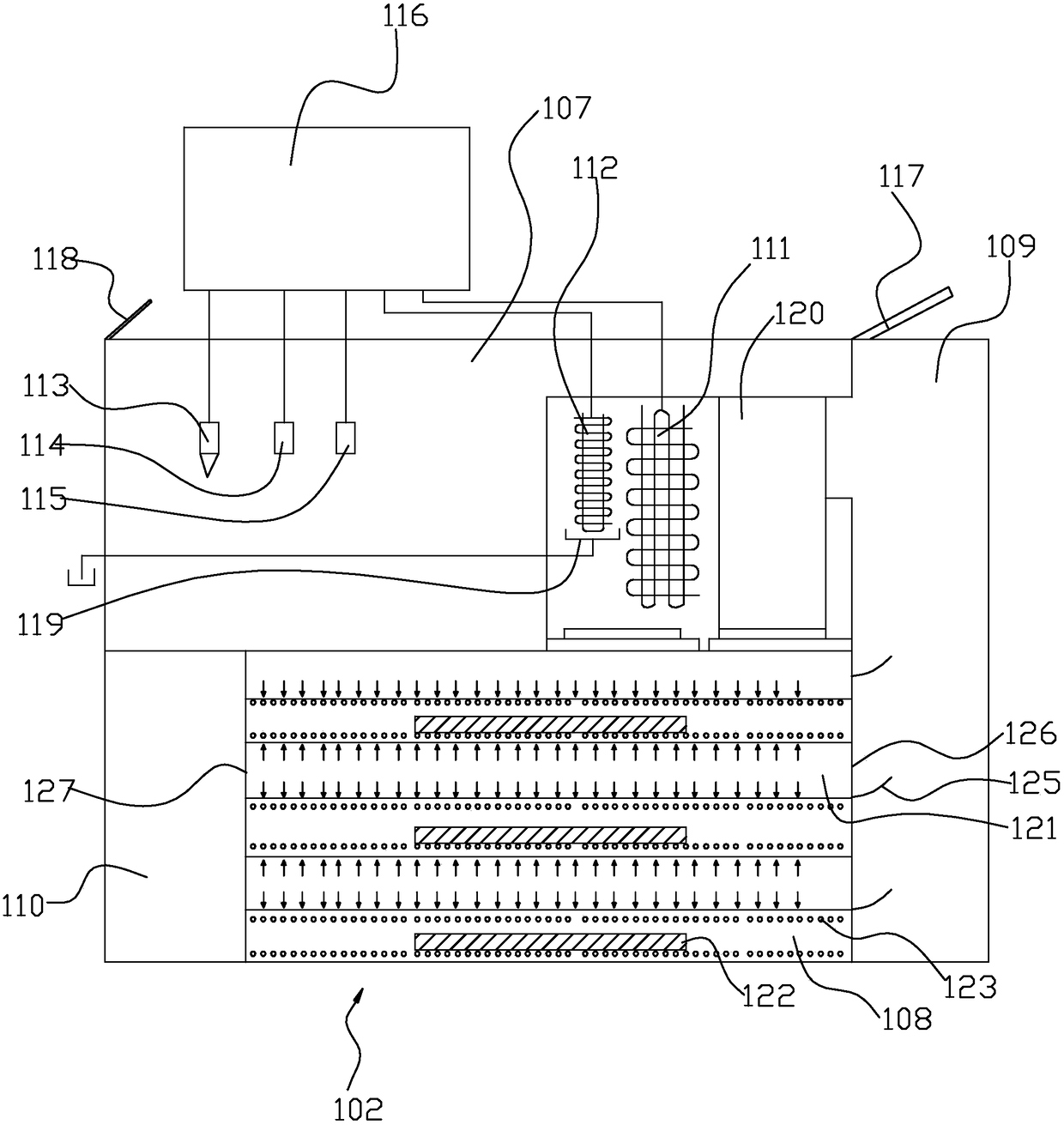

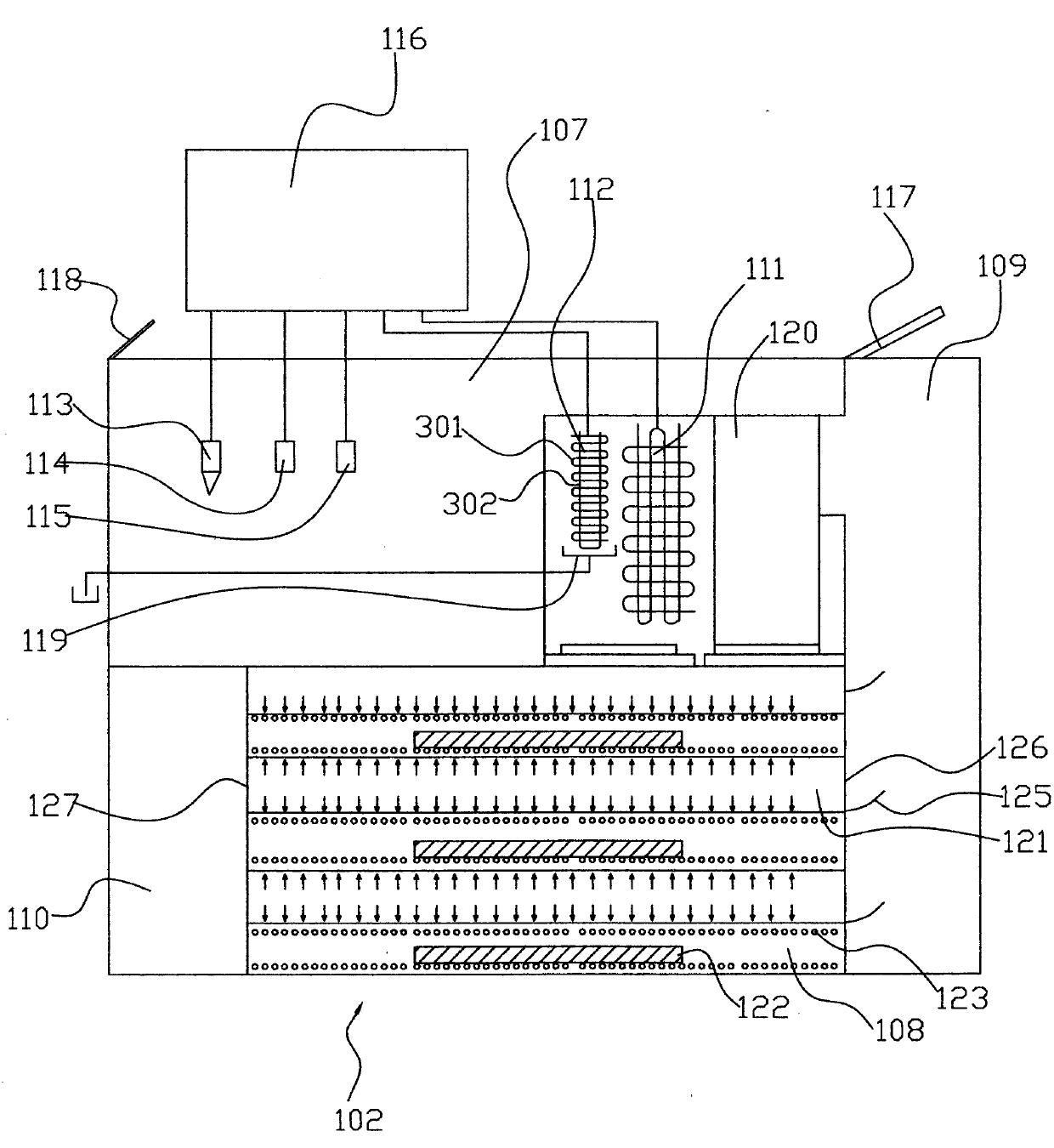

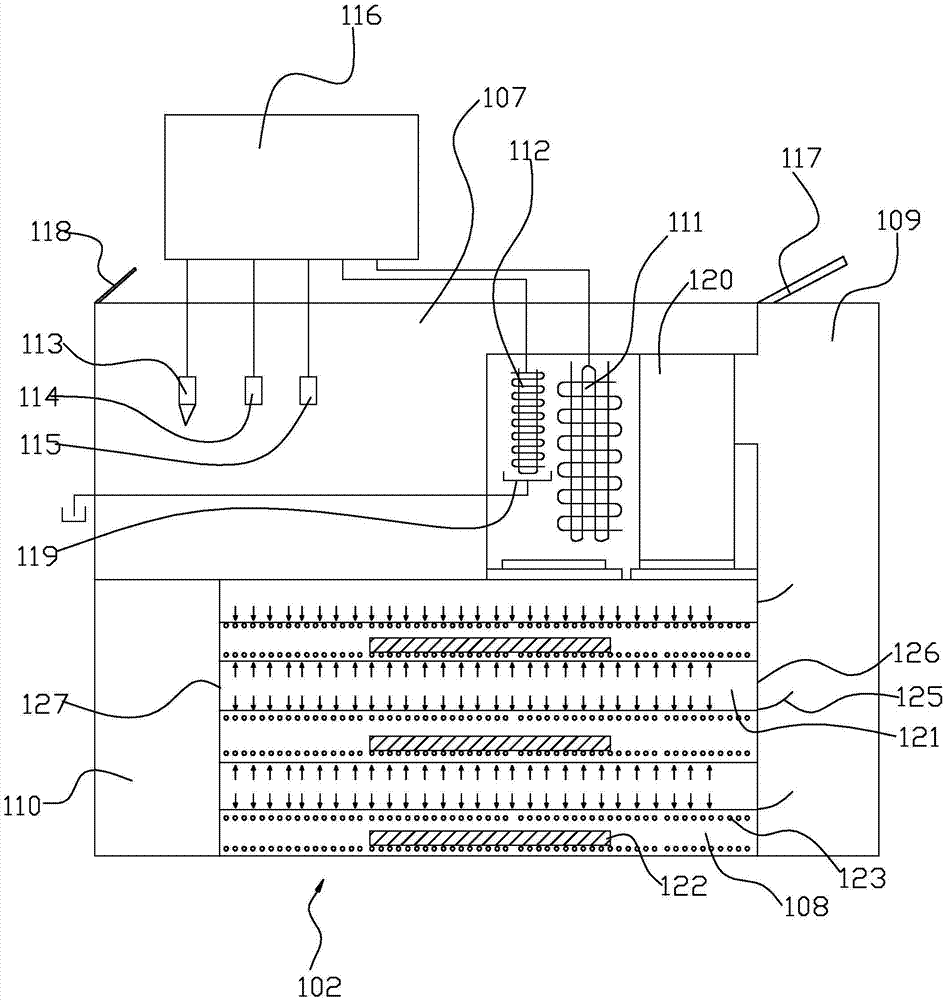

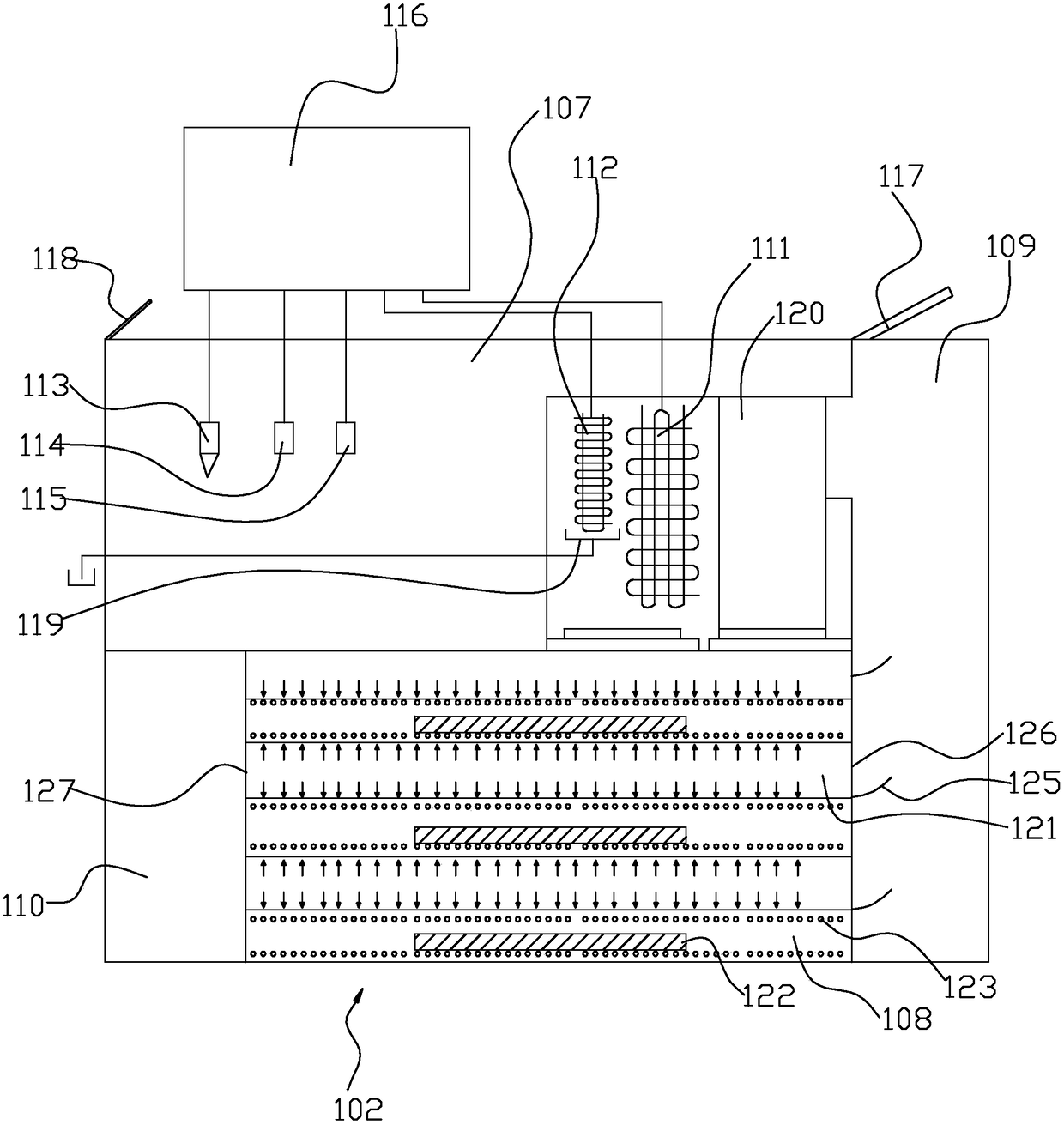

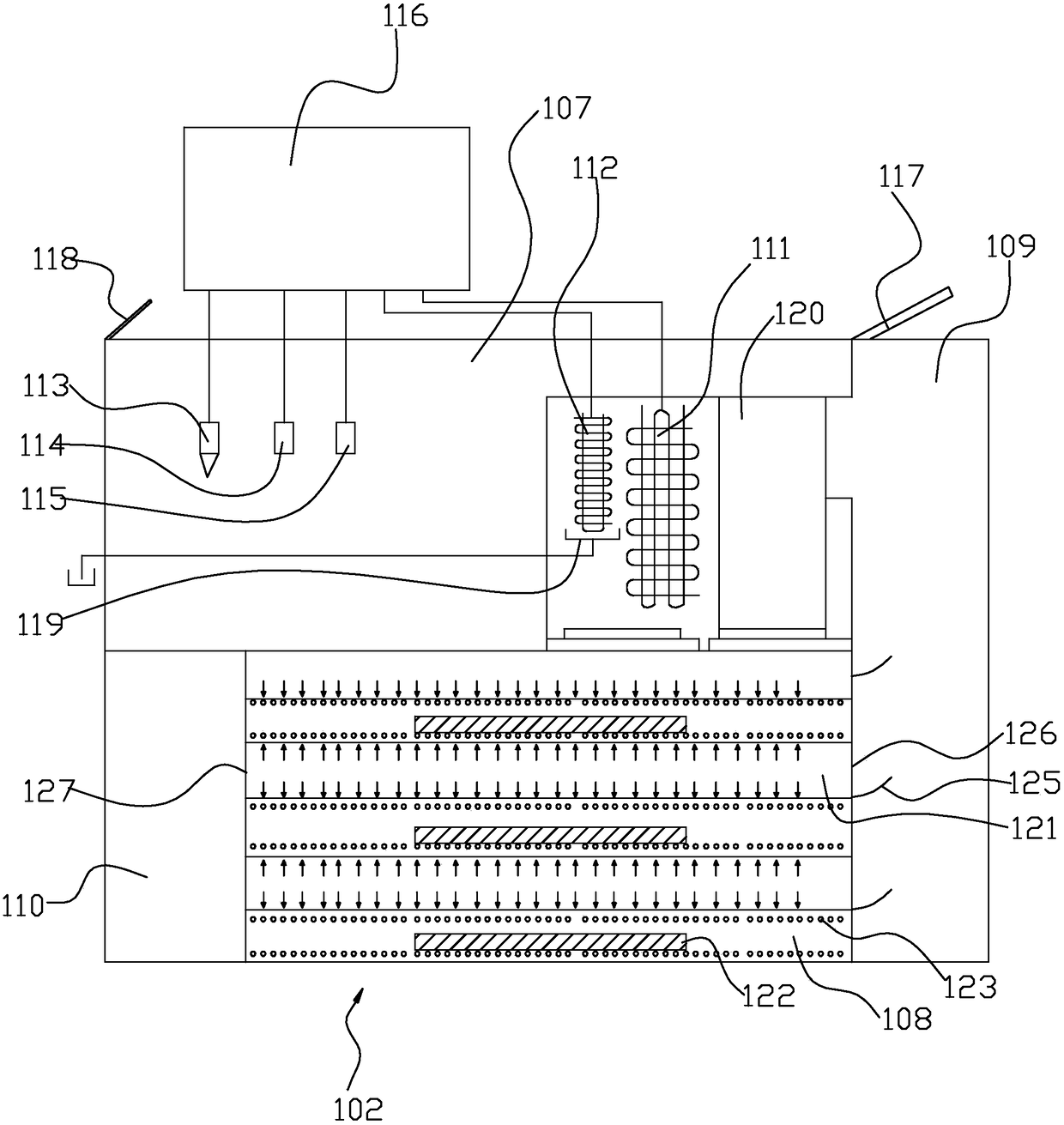

Multifunctional air conditioning system

InactiveCN108204735AFast dryingDry evenlyDrying gas arrangementsLeather dryingInlet channelEngineering

The invention discloses a multifunctional air conditioning system. The multifunctional air conditioning system is used for drying a layered soft product and comprises at least one adjusting unit. Eachadjusting unit comprises an adjusting chamber, a transmission chamber, an air inlet channel and an air return channel, wherein the air inlet channels and the air return channels communicate with theadjusting chambers and the transmission chambers. Each adjusting chamber is provided with a heating device and an air blower. Each adjusting chamber is internally and further provided with a refrigeration dehumidifying device, a temperature detector, a humidity detector, a spraying gun used for increasing the hot air humidity in the adjusting units, and a full-computer real-time controlled controller, wherein the refrigeration dehumidifying devices, the temperature detectors and the humidity detectors are matched mutually, and the controllers control the heating devices, the refrigeration dehumidifying devices, the temperature detectors, the humidity detectors and the spraying guns.

Owner:王俊杰

Microcomputer intelligent control dryer

InactiveCN110030817AFast dryingImprove drying efficiencyDrying gas arrangementsDrying machines with progressive movementsReturn channelEngineering

The invention discloses a microcomputer intelligent control dryer used for drying a layered flexible product. The microcomputer intelligent control dryer comprises at least one adjusting unit; each adjusting unit comprises an adjusting chamber, a transmission chamber, an air inlet channel and an air return channel, the air inlet channel and the air return channel communicate with the adjusting chamber and the transmission chamber; each adjusting chamber is provided with a heating device and an air blower; and a refrigerating and dehumidifying device, a temperature detector, a humidity detector, a spraying gun used for increasing the humidity of hot air in the adjusting unit and a controller used for controlling the heating device, the refrigerating and dehumidifying device, the temperaturedetector, the humidity detector and the spraying gun to achieve full-computer real-time control are arranged in each adjusting chamber, and the refrigerating and dehumidifying device, the temperaturedetector, the humidity detector, the spraying gun and the controller in each adjusting chamber cooperate with one another.

Owner:张荣生

Humidity adjusting drying machine adjusting temperature and humidity easily

InactiveCN106916913AFast dryingDry evenlySkins/hides/leather/fur manufacturing apparatusLeather dryingInlet channelAir blower

The invention discloses a humidity adjusting drying machine adjusting temperature and humidity easily. The humidity adjusting drying machine is used for drying lamellar soft products and comprises at least one adjusting unit. Each adjusting unit comprises an adjusting chamber, a transmission chamber, an air inlet channel and an air return channel, wherein the air inlet channel and the air return channel communicate with the adjusting chamber and the transmission chamber, the adjusting chamber is provided with a heating device and an air blower and further provided with a refrigeration dehumidifying device, a hygrosensor, a humidity detector, a spraying gun and a controller, the refrigeration dehumidifying device, the hygrosensor and the humidity detector are matched with one another, the spraying gun is used for increasing the humidity of hot air in the adjusting unit, and the controller is used for controlling the heating device, the refrigeration dehumidifying device, the hygrosensor, the humidity detector and the spraying gun in real time in a full-computer manner.

Owner:王俊杰

Humidity adjusting and drying machine for easily adjusting temperature and humidity

InactiveCN109140923AFast dryingDry evenlyDrying gas arrangementsDrying machines with local agitationRegulation temperatureEngineering

The invention discloses a humidity adjusting and drying machine for easily adjusting temperature and humidity. The humidity adjusting and drying machine is used for drying layered soft products, and comprises at least one adjusting unit; and the adjusting unit comprises an adjusting chamber, a transmission chamber, an air inlet passage and an air return passage, the air inlet passage and the air return passage communicate with the adjusting chamber and the transmission chamber, the adjusting chamber is also provided with a heating device, a blower, a refrigerating and dehumidifying device, a temperature detector, a humidity detector, a spraying gun and a controller which are matched with each other, the spraying gun is used for increasing the hot air humidity in the adjusting unit, and thecontroller is used for controlling the full-computer real-time control of the heating device, the refrigerating and dehumidifying device, the temperature detector, the humidity detector and the spraying gun.

Owner:钟舒

Fixing device and fixing method of embedded steel edge rubber water stop for underground structure

PendingCN110984240APrecise positioningNo deformationArtificial islandsProtective foundationWater stopMaterial resources

The invention provides a fixing device of an embedded steel edge rubber water stop for a construction joint part of an underground structure. The device comprises the embedded steel edge rubber waterstop, a fixing screw and a fixing nut. Fixing limit holes are vertically aligned in the steel edges of the two sides of the embedded steel edge rubber water stop and formed with longitudinal intervalsbeing not greater than 600 mm. The invention further provides a fixing method for the fixing device of the steel edge rubber water stop for the underground structure. The fixing screw passes throughthe fixing limit holes, the two sides of the fixing screw are in adaptive connection with the nut, one end of the screw is fixedly connected with the steel edge rubber water stop, the other end of thescrew is welded to structural steel bars of a corresponding part, when one end of the fixing screw cannot find structural steel bars of a corresponding part, a transverse bar can be accessorily welded to one end of the screw, then the two ends of the transverse bar are welded to structural steel bars of a corresponding part. The situation that distortion and dislocation of the rubber water stop affects the strength and effect of water stopping in the casting and compacting of concrete is avoided, manpower and material resources are saved, and the construction efficiency is improved.

Owner:MCC TIANGONG GROUP

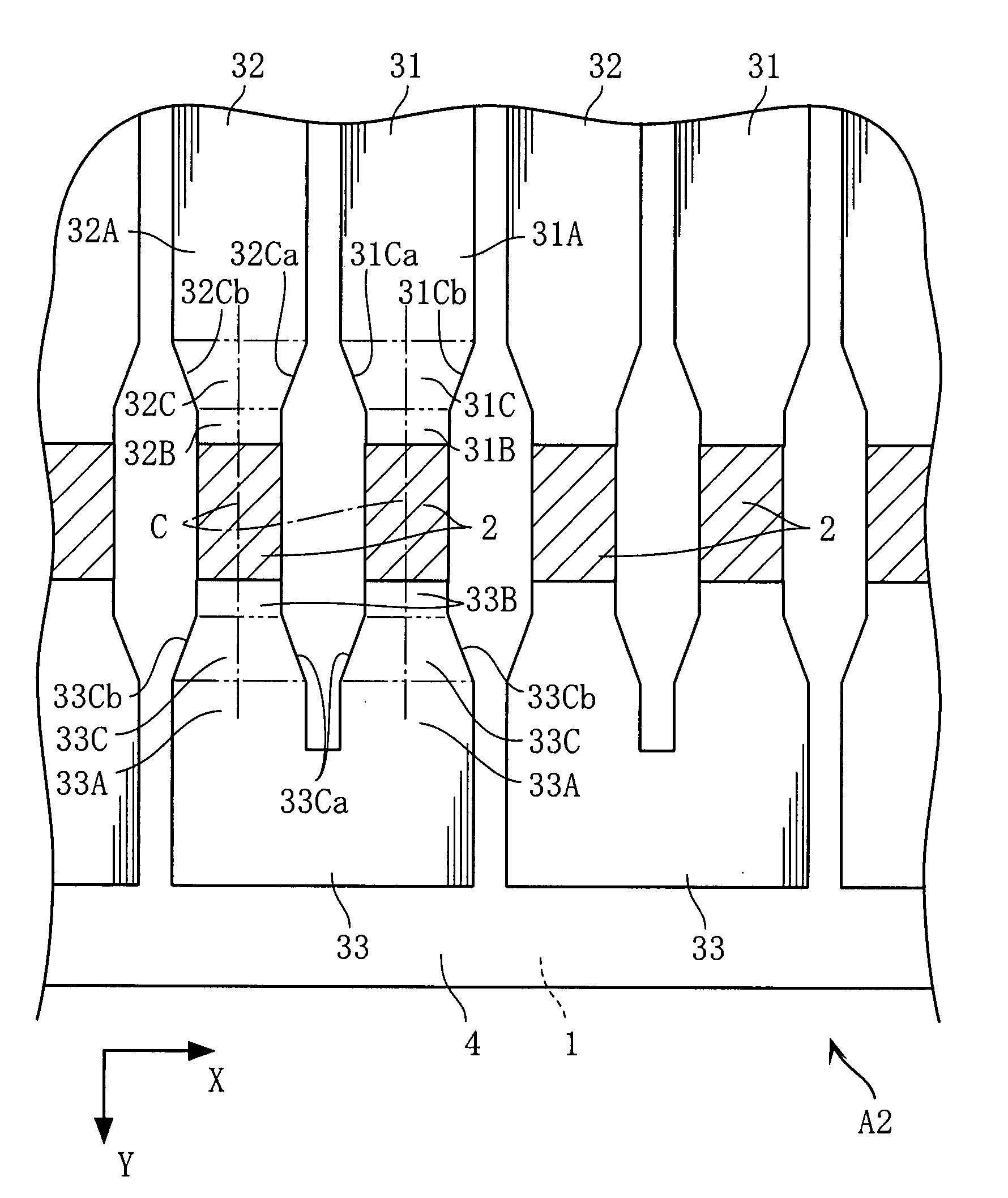

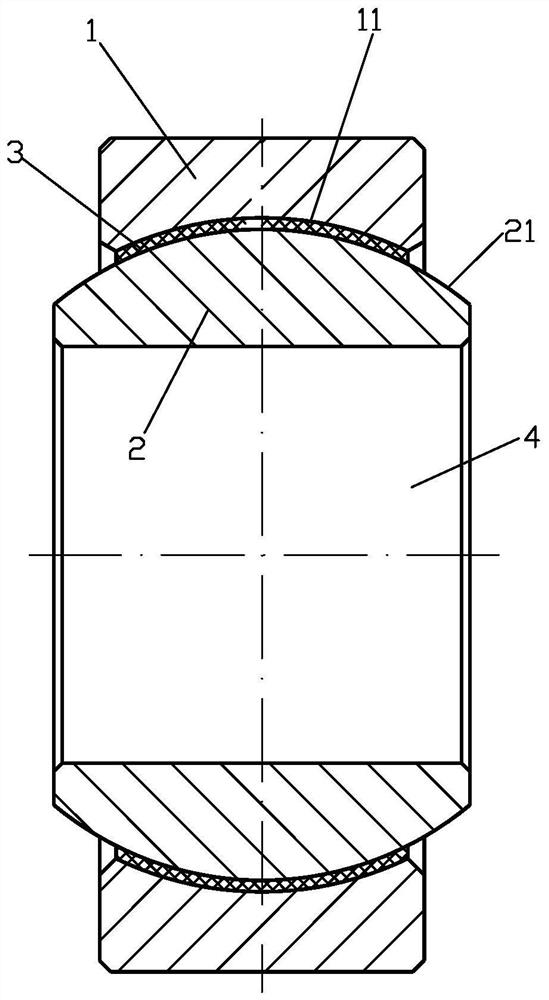

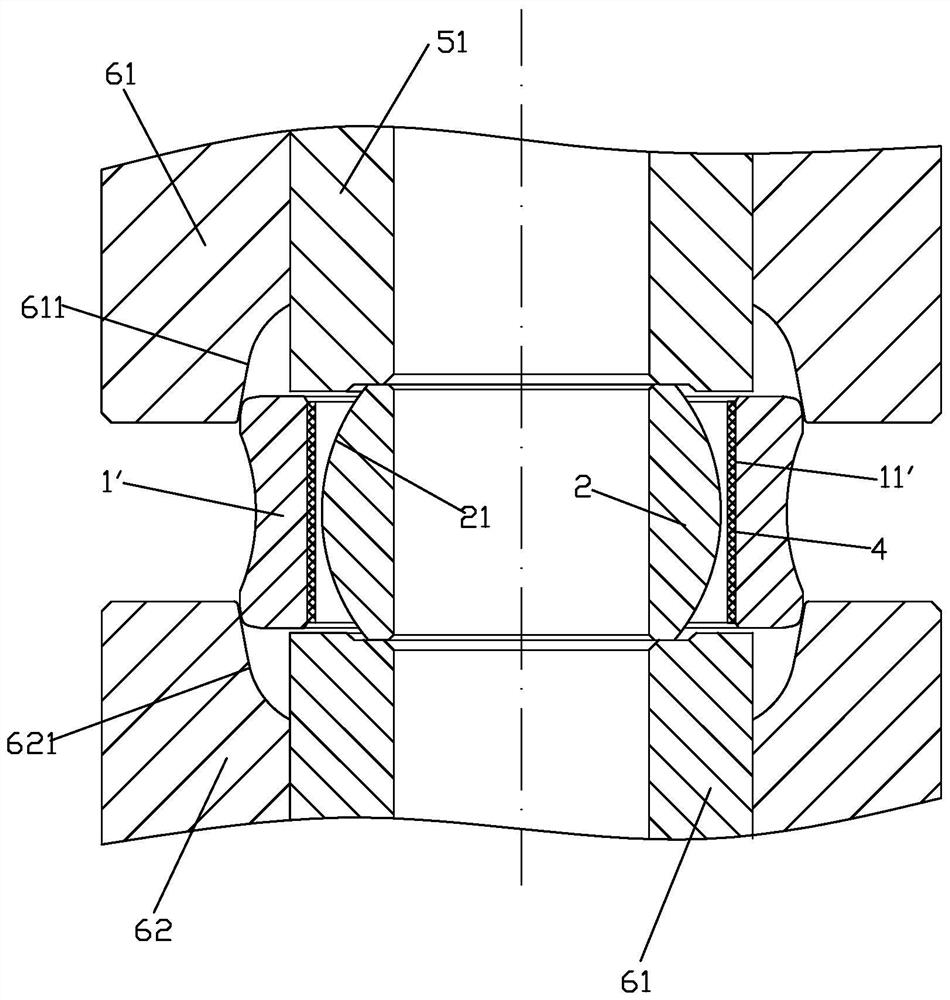

A method of manufacturing molded self-lubricating joint bearings

ActiveCN110131307BOval smallEliminate gapsBearing componentsSliding contact bearingsDeformation effectMachining

The invention discloses a manufacturing method of a molding type self-lubricating knuckle bearing. The manufacturing method comprises the following steps that an outer ring semi-finished product and an inner ring are machined, wherein the outer ring semi-finished product is provided with a through hole; an auxiliary gasket layer is placed in the through hole, the inner ring is placed in the through hole, the auxiliary gasket layer is located between the inner ring and the outer ring semi-finished product, the outer ring semi-finished product is extruded, and the extruded auxiliary gasket layeris filled with a cavity formed between the inner ring and the outer ring semi-finished product; an outer rotative surface of outer ring semi-finished product is machined, two ends of the outer ring semi-finished product are machined to remove margin at the two ends of the outer ring semi-finished product, the auxiliary gasket layer is removed, and a lubricating material is a cavity filled betweenan outer ring and the inner ring. The manufacturing method has the following advantages that the auxiliary gasket layer is introduced, the deformation effect of the outer ring is supported in the extrusion process, so that the shape of extrusion forming shape is accurate, the size precision is high, the outer ring ellipse is small after extrusion, twisting is avoided, the gasket layer can eliminate the gap between the inner ring and the outer ring after extruded, and the coaxiality and the cavity symmetry degree of the inner ring and the outer ring in the extruded machining are easy to control, so that the radial sealing degree and the circumferential sealing degree of the bearing can be accurately controlled.

Owner:FUJIAN LONGXI BEARING (GROUP) CO LTD

Self-locking supporting device compatible with wiring function

PendingCN110890730AStable supportSolve the problems of connection, security and concealmentElectrical apparatusEngineeringStructural engineering

Owner:深圳市烽云技术有限公司

Control method of hydraulic jacking system of transporting girder vehicle

ActiveCN102700448BNot distortedNo tiltVehicle with parallel load movementProportional controlElectrical control

Owner:徐州徐工能源装备有限公司

Rescue robot storage system

The invention relates to a rescue robot accommodating system. The rescue robot accommodating system comprises a personnel accommodating device (8), a middle transition conveying device (6) and a shovel-like pickup device (4), wherein the personnel accommodating device (8) is arranged on a robot frame (2); the shovel-like pickup device (4) is shovel-shaped, and is connected to the front end of the middle transition conveying device (6) in a hinging way; the back ends of short-range electric push rods (5,5') are hinged to the middle transition conveying device (6); the front ends of the short-range electric push rods (5,5') are hinged to a short-range electric push rod lower support on the shovel-like pickup device (4); the personnel accommodating device (8), the middle transition conveying device (6) and the shovel-like pickup device (4) are all provided with conveying belts (11) which can move bilaterally under the driving action of an electric drum and are used for carrying and moving wounded persons. By adopting the rescue robot accommodating system, the carrying and moving work of trapped and critically-wounded personnel can be finished.

Owner:SANITARY EQUIP INST ACAD OF MILITARY MEDICAL SCI PLA

Soft leather air-handling system

InactiveCN108070681AFast dryingDry evenlySkins/hides/leather/fur manufacturing apparatusLeather dryingProcess engineeringHandling system

The invention discloses a soft leather air-handling system which is used for drying layered soft products. The soft leather air-handling system comprises one or more regulating units. The regulating units comprise regulating chambers, drive chambers, air inlet ducts and air return ducts, wherein the air inlet ducts and the air return ducts communicate with the regulating chambers and the drive chambers. The regulating chambers are provided with heating devices and air blowers. Refrigeration dehumidifying devices, temperature sensors, humidity sensors, spray pistols and whole-computer real-timecontrol controllers are further arranged inside the regulating chambers, wherein the refrigeration dehumidifying devices, the temperature sensors and the humidity sensors are matched with one another; the spray pistols are used for increasing hot-gas humidity in the regulating units; and the whole-computer real-time control controllers control the heating devices, the refrigeration dehumidifyingdevices, the temperature sensors, the humidity sensors and the spray pistols.

Owner:王俊杰

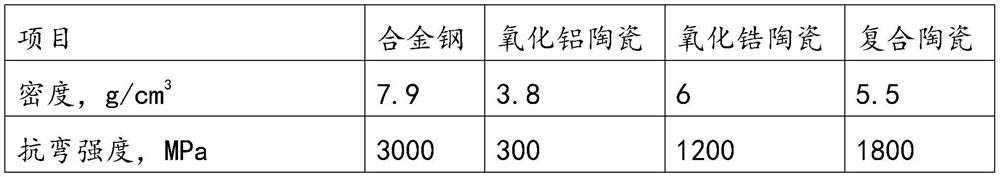

Composite ceramic and preparation method thereof and application of composite ceramic in preparation of linear guide rail

InactiveCN113773077AHigh hardnessImproved accuracy and stabilityLinear bearingsLow noiseComposite ceramic

The invention discloses a composite ceramic. The composite ceramic is mainly prepared by sintering the following raw materials in percentage by weight: 78-81% of zirconium oxide with a particle size of 0.2-0.4 [mu]m, 14-16% of aluminum oxide with a particle size of 0.23 to 0.38 [mu]m and 4-6% of yttrium oxide. Compared with the prior art, the composite ceramic disclosed by the invention has the advantages of wear resistance, high hardness, low noise, impact resistance, difficulty in cracking, strong acid and alkali resistance, insulation, antimagnetism and the like, is a good material for the linear guide rail, can enable the linear guide rail to be longer in service life and higher in precision stability, and is suitable for working in a severe environment.

Owner:YIXING YUNBO TECH

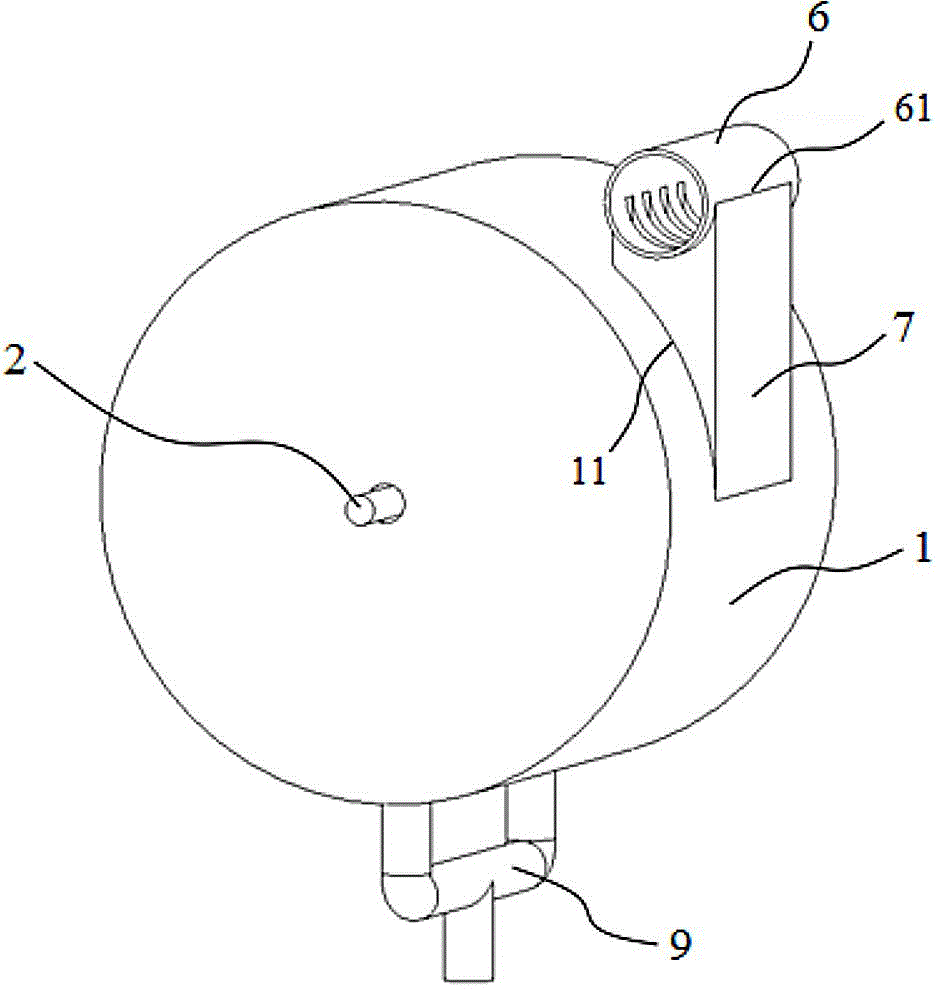

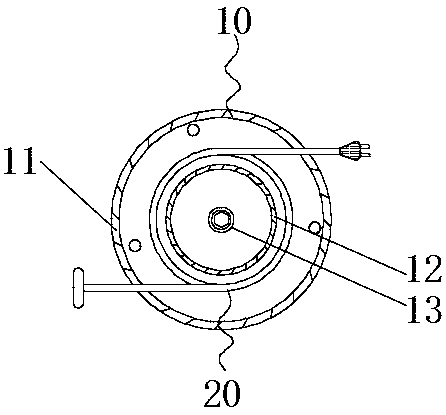

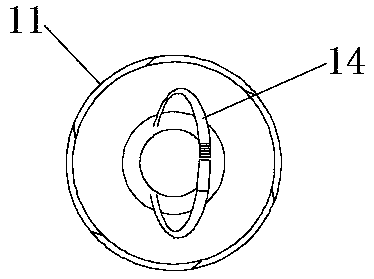

LED lamp strip with storage and release functions

InactiveCN110715193ANot distortedNot subject to dropElectric circuit arrangementsElectric lightingComputer hardwareLED lamp

The invention discloses an LED lamp strip with storage and release functions. The LED lamp strip comprises a storage and release assembly and an illumination assembly, wherein the storage and releaseassembly comprises a storage and release case, a rolling wheel, a rotating roller and a connecting ring; an accommodating cavity is arranged inside the storage and release case; the rotating roller isaccommodated in the accommodating cavity; the inner side all of the storage and release case is fixedly connected with one end of the rotating roller; the other end of the rotating roller is fixed through screws; the rolling wheel is arranged at the outer side wall of the rotating roller; the rolling wheel is rotationally connected with the rotating roller; the connecting ring is positioned on the outer side wall of the storage and release case; and the connecting ring and the storage and release case are rotationally connected through a second rotating shaft. A worker pulls out the LED lampstirp by pulling an iron sheet, so that the LED lamp stirp cannot generate distortion, and the LED lamp cannot fall off; loss caused on enterprises is avoided; when the LED lamp is recovered after being used, the worker can directly store the LED lamp strip into a storage and release box; the recovery speed is accelerated through the storage and release box; and convenience is brought to the worker.

Owner:JIANGSU XIYI HIGH NEW DISTRICT TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com