Microcomputer intelligent control dryer

An intelligent control and dryer technology, applied in leather drying, progressive dryer, drying solid materials, etc., can solve the problems of poor temperature and humidity adjustment ability, reduce machine efficiency, and long time consumption, and achieve temperature and humidity adjustment Strong capacity, improved drying efficiency, and accelerated drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

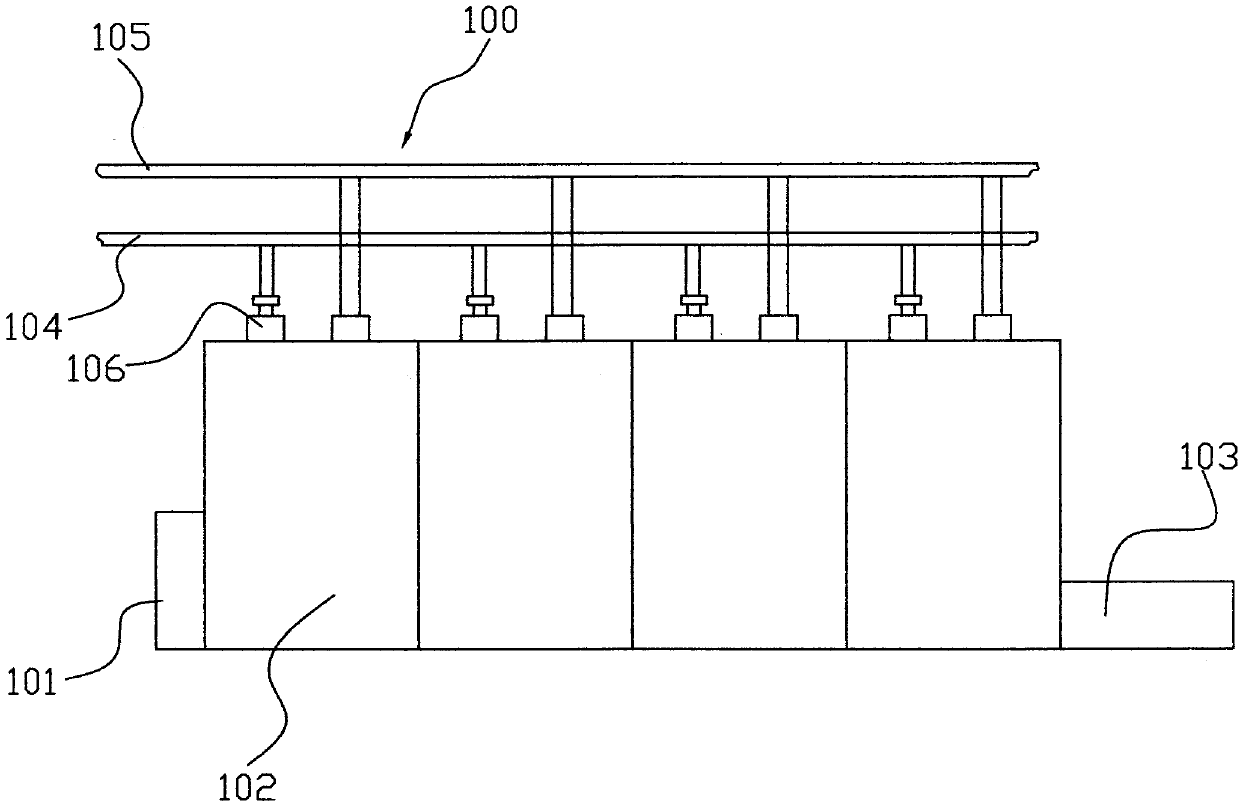

[0013] refer to Figure 1-2 , a microcomputer intelligent control dryer 100 includes a plurality of adjustment units 102, wherein the leftmost adjustment unit 102 has a leather product inlet 101, and the leather products to be treated enter here to adjust and dry from the rightmost adjustment unit 102. The leather goods outlet 103 sends out. In addition, a hot water input pipe 104 is input to each conditioning unit 102 through a control valve 106 . A hot water outlet pipe 105 is also communicated with all conditioning units 102 at the same time.

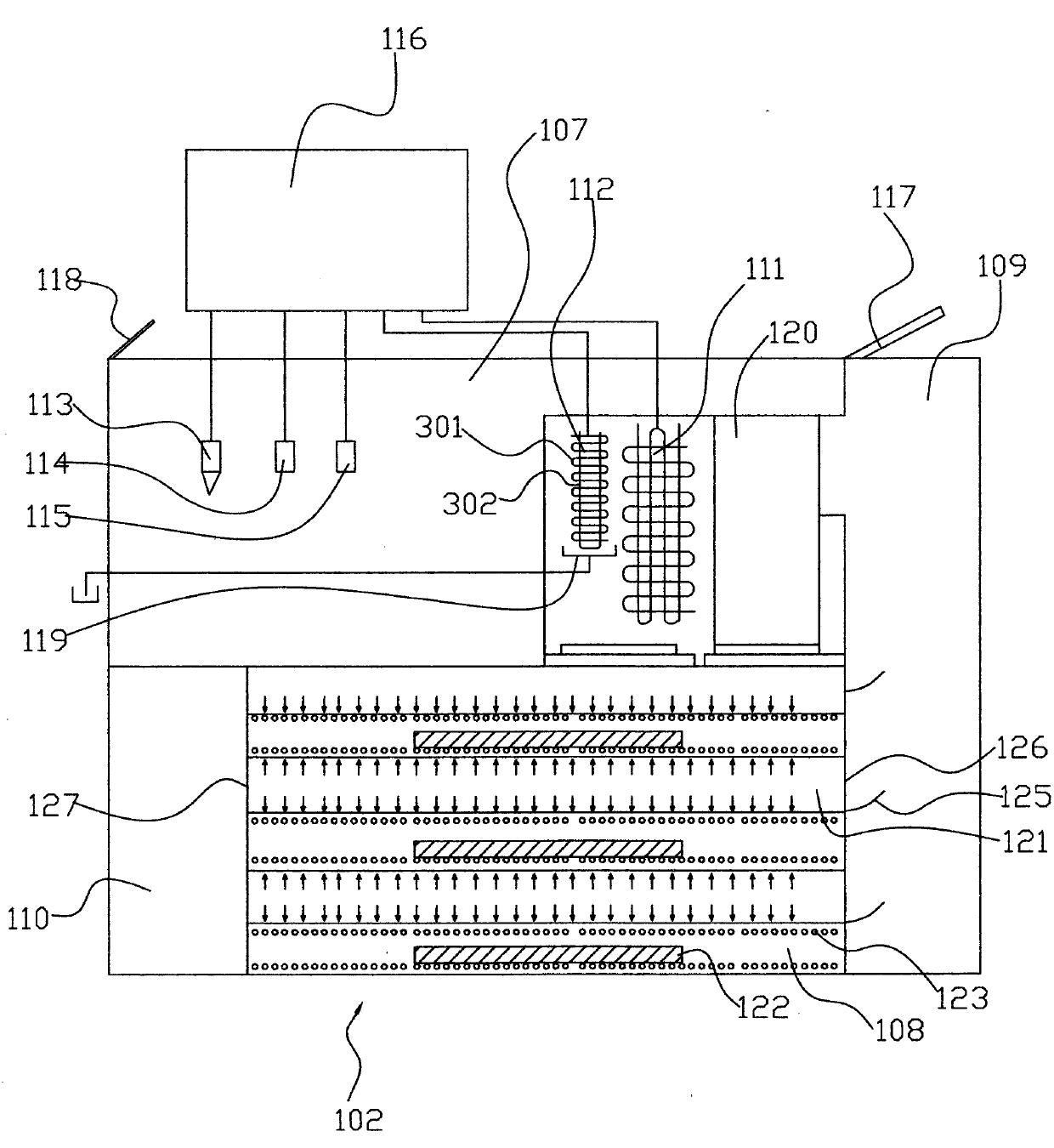

[0014] A typical conditioning unit 102 includes a conditioning chamber 107 for adjusting drying temperature and humidity, a transmission chamber 108 for moving the product, an air inlet channel 109 and an air return channel 110 communicating with the conditioning chamber 107 and the transmission chamber 108 . The conditioning chamber 107 has a heating device 111 for heating the gas and a blower 120 for forming circulating gas. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com