A method of manufacturing molded self-lubricating joint bearings

A kind of joint bearing and manufacturing method technology, applied in the direction of sliding contact bearing, bearing, shaft and bearing, etc., can solve the difficulty of processing and positioning, poor radial and circumferential tightness of bearing, and poor product coaxiality and symmetry. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

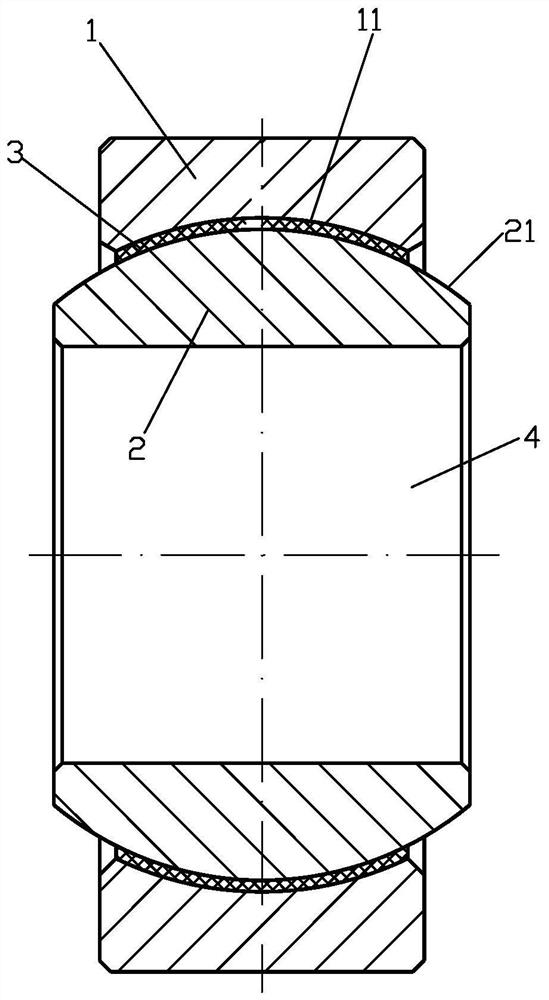

[0025] Please check figure 1 , The molded self-lubricating joint bearing includes an outer ring 1 and an inner ring 2, the outer ring 1 is provided with a through hole, the through hole wall is an inner spherical surface 11, the inner ring 2 has an outer spherical surface 21, the inner ring 2 is located In the through hole of the outer ring 1, a cavity is formed between the inner spherical surface 11 of the outer ring 1 and the outer spherical surface 21 of the inner ring 2, and the lubricating material 3 is injected into the cavity.

[0026] A manufacturing method of molded self-lubricating joint bearing includes:

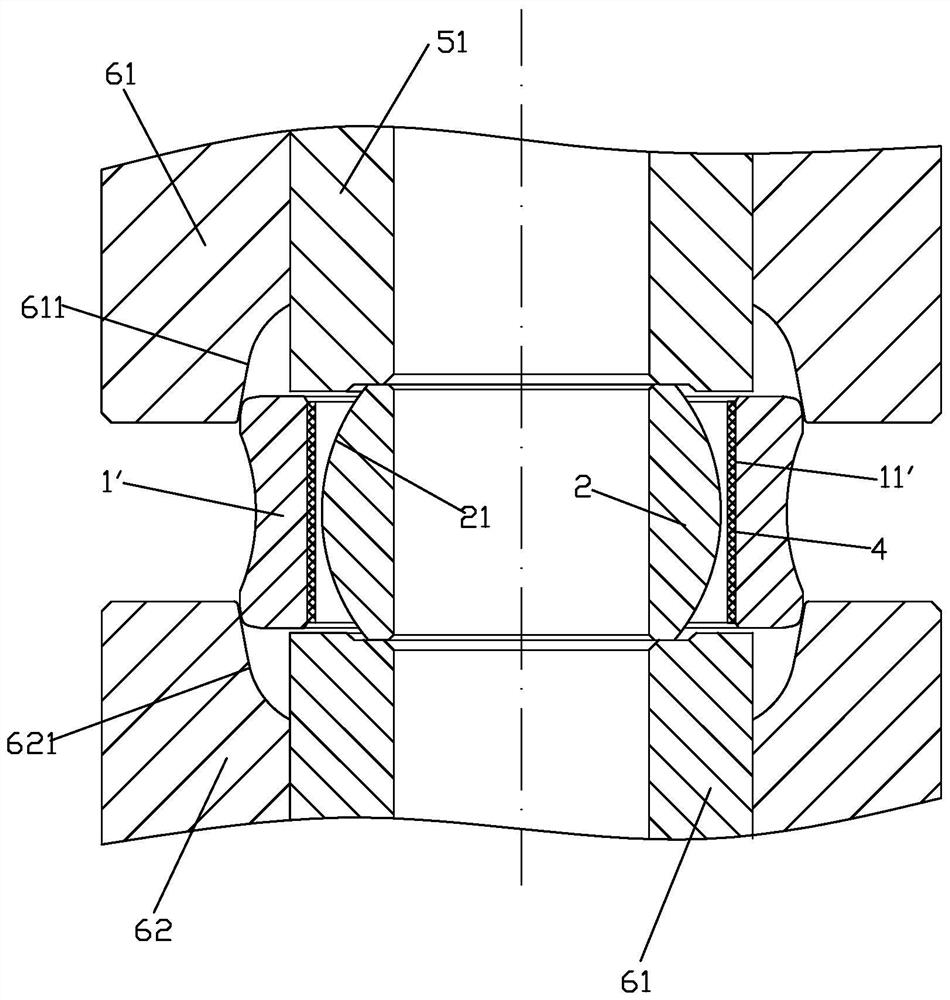

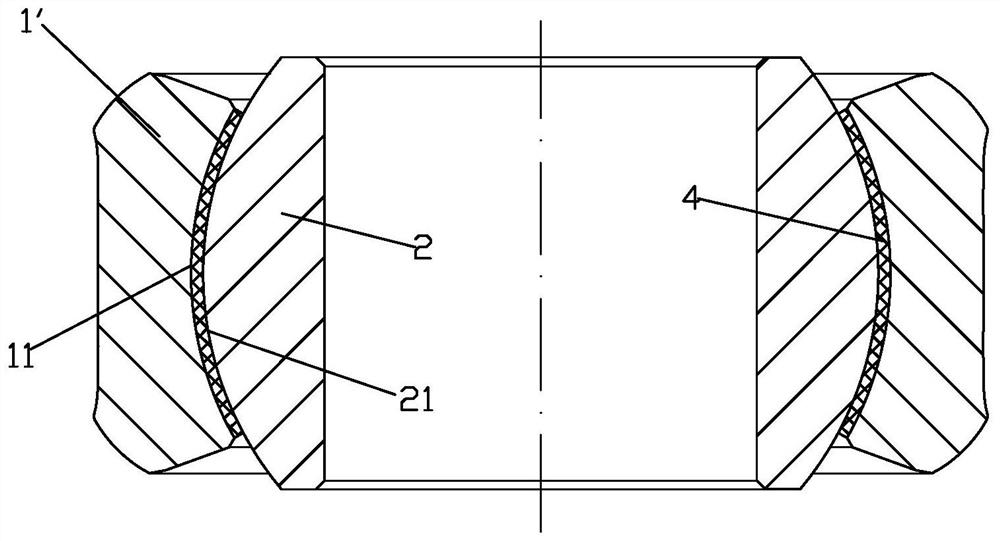

[0027] Step 1. Process the semi-finished outer ring 1'and the inner ring 2. The semi-finished outer ring 1'has a through hole 11'. The through hole 11' is cylindrical, and the inner ring 2 is provided with an axial through hole 22;

[0028] Step 2. Put the auxiliary cushion layer 4 into the through hole of the semi-finished outer ring 1'; the auxiliary cushion layer is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com