Fixing device and fixing method of embedded steel edge rubber water stop for underground structure

A rubber waterstop and fixing device technology, which is applied to underwater structures, protection devices, infrastructure engineering and other directions, can solve the problems of time-consuming, laborious, and affect the waterstop effect of waterstop fixing, so as to avoid inaccurate positioning. , The effect of high construction quality and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

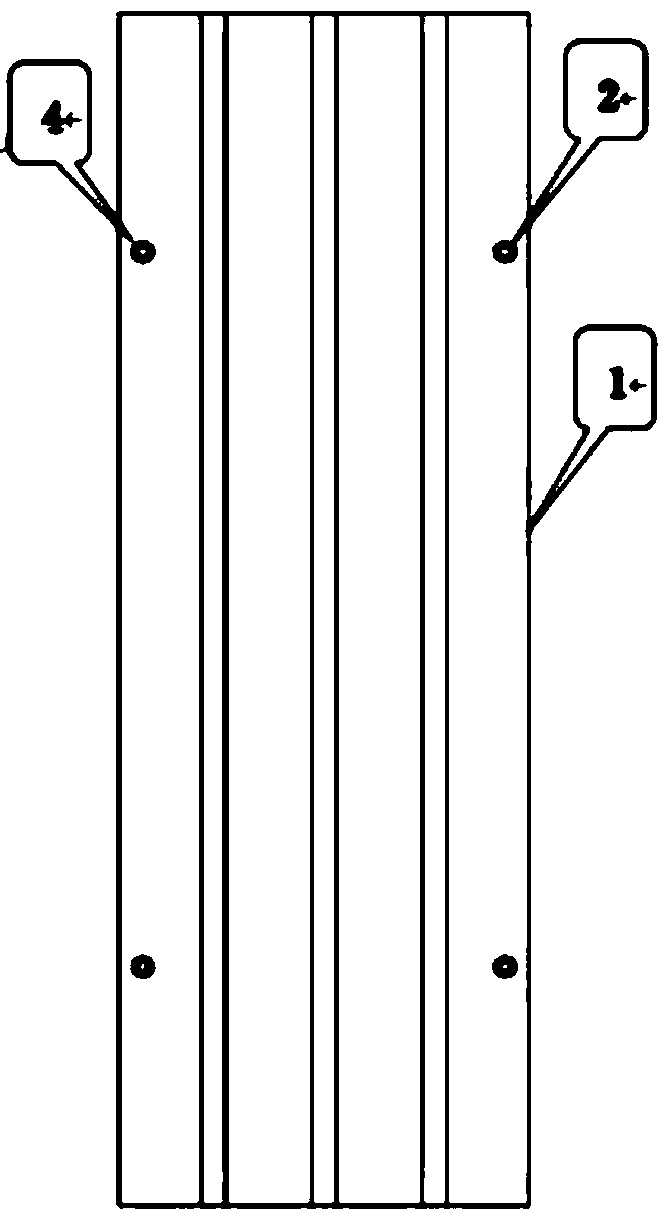

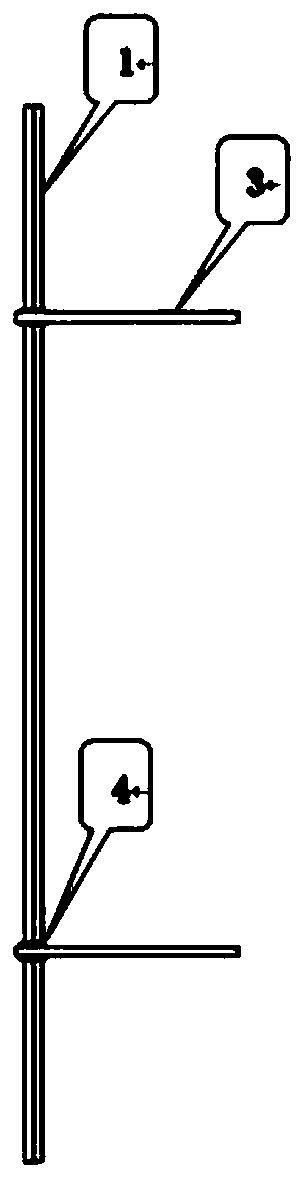

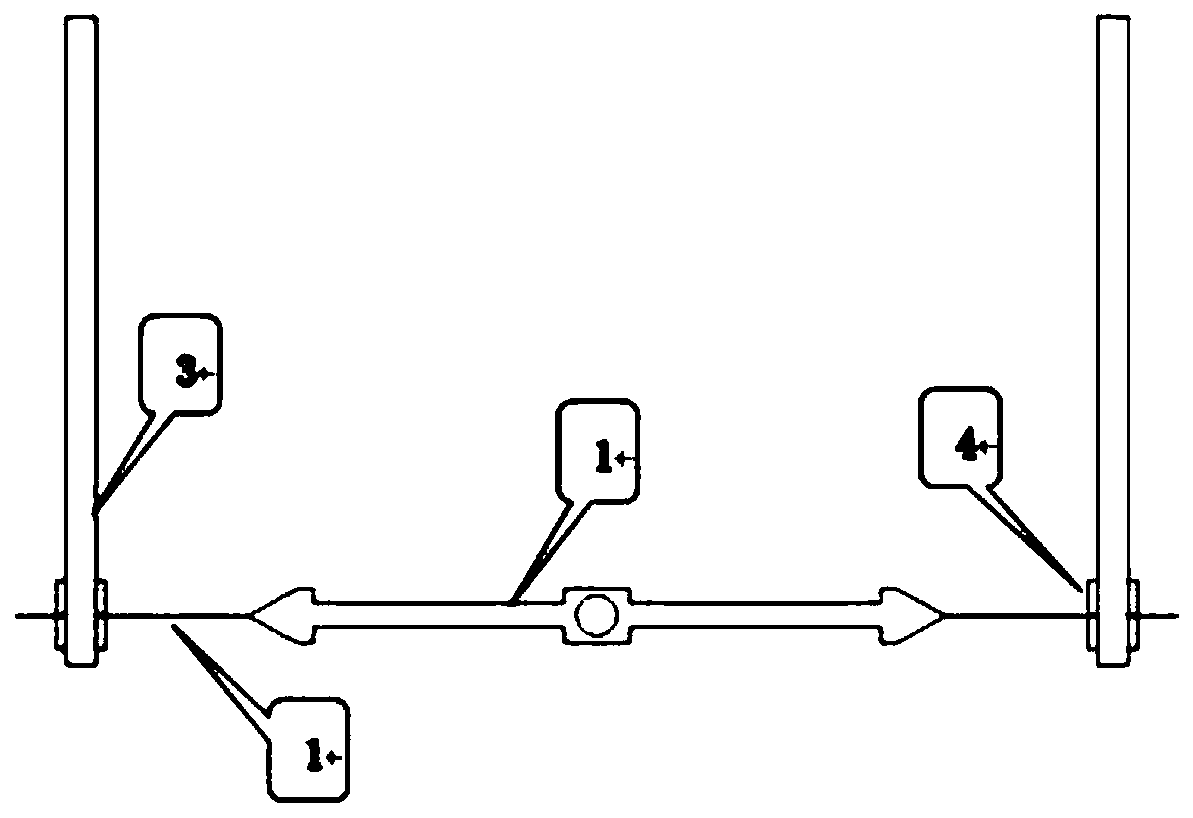

[0029] Such as Figure 1-Figure 3 As shown together, the fixing device for the buried steel edge rubber waterstop in the underground structure of the embodiment of the present invention includes the buried steel edge rubber waterstop 1, the fixed limit hole 2, the fixed screw rod 3, and the fixed nut 4; The steel edges on both sides of the buried steel edge rubber waterstop 1 are vertically aligned, and the fixed limit holes 2 are set at an interval of no more than 600mm. With connection, one end of the fixed screw 3 is fixedly connected with the buried steel edge rubber waterstop 1; the other end of the fixed screw 3 is welded to the structural steel bar at the corresponding part, when the structural steel bar at the corresponding part cannot be found at one end of the fixed screw 3 , a transverse bar can be welded at one end of the fixed screw rod 3, and then the two ends of the transverse bar are welded on the structural steel bar at the corresponding position. The diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com