Composite ceramic and preparation method thereof and application of composite ceramic in preparation of linear guide rail

A composite ceramic and linear guide technology, applied in the field of ceramics, can solve problems such as performance to be improved, and achieve the effects of reducing the premature peeling of the shaft, high precision stability, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) By 81wt% zirconia powder (0.2~0.4μm in particle size), 14wt% alumina powder (0.23~0.38μm in particle size), 5wt% yttrium oxide (purity 99.9%), in sand mill Thoroughly grind into a uniform mixed powder.

[0034] (2) Add conventional granulation aids (defoamer 0.3wt% / powder, dispersant 0.1wt% / powder, viscous agent 4wt% / powder) into the mixed powder and granulate through a prilling tower to obtain granules.

[0035] (3) Put the granular material into a mold, and then use an isostatic press to press and shape it under a pressure above 200 MPa to obtain a ceramic blank.

[0036] (4) The pottery blank is transferred into a high-temperature furnace and sintered at 1500-1600°C for 2-12 hours to form a composite ceramic.

[0037] (5) Finally, it is finished to the precision size used.

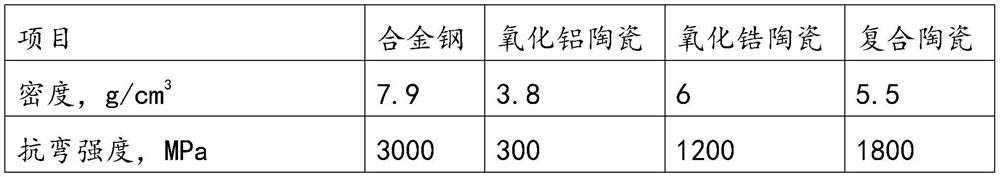

[0038] Table 1 Performance comparison of different materials

[0039]

[0040]

Embodiment 2

[0042] (1) By 78wt% zirconia powder, 16wt% alumina powder (see Table 2 for particle size ratio), 6wt% yttrium oxide (purity 99.9%), fully grind into a uniform mixed powder in a sand mill .

[0043] (2) Add granulation aids (defoamer 0.3wt% / powder, dispersant 0.1wt% / powder, viscous agent 4wt% / powder) into the mixed powder and granulate through a granulation tower to obtain granules.

[0044] (3) Put the granular material into a mold, and then use an isostatic press to press and shape it under a pressure above 200 MPa to obtain a ceramic blank.

[0045] (4) The pottery blank is transferred into a high-temperature furnace and sintered at 1500-1600°C for 2-12 hours to form a composite ceramic.

[0046] (5) Finally, it is finished to the precision size used.

[0047] Table 2 particle size ratio is as follows:

[0048] Zirconia μm Alumina μm Recipe 1 0.85 0.91 Recipe 2 0.64 0.37 Recipe 3 0.56 0.43 Recipe 4 0.35 0.16 Recipe 5 0.35 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com