Urea heating liquid return pipe

A liquid return pipe and urea technology, applied in the component field of automobile exhaust gas treatment system, can solve problems such as unsatisfactory heating effect, unrecognizable and captured signals by computer, and failure of normal operation of SCR exhaust gas treatment system, etc., achieving fast speed , the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

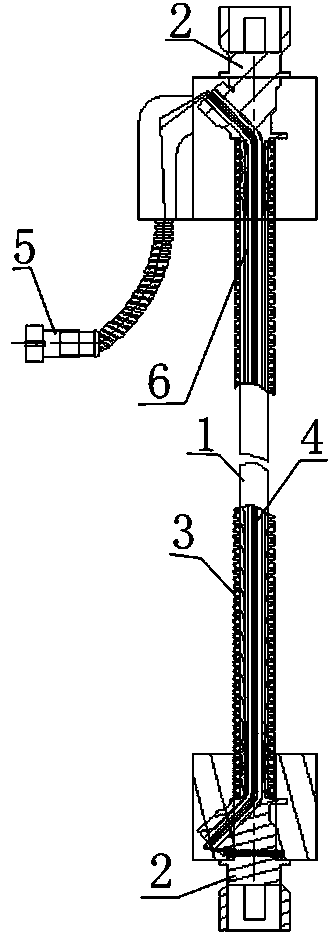

[0017] The present invention as figure 1 shown.

[0018] The urea heating liquid return pipe includes the urea liquid return pipe 1, and the two ends of the urea liquid return pipe 1 are respectively equipped with quick-connect joints 2, the outside of the urea liquid return pipe 1 is provided with a bellows 3, and the urea liquid return pipe 1 is provided with a There is a heating wire or a heating belt 4, and the heating wire or heating belt 4 is placed in the center through the push-in connectors at both ends in the urea return pipe 1, and connected through the outlet plug 5 provided on the side wall of the quick-connect connector 2.

[0019] A temperature sensor 6 is installed inside the urea liquid return pipe 1, and is wired through the outlet plug 5.

[0020] The heating wire or heating belt 4 is solidified inside the quick-plug connector 2 at both ends in the urea return pipe 1 ;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com