Bladeless turbine engine

A turbine engine, fanless technology, used in engine components, machines/engines, non-variable-capacity engines, etc., can solve the problem that the centrifugal force of the disc is easy to be stretched, cannot be practically applied, and the disc cannot be overheated. and other problems, to achieve the effect of improving thermodynamic efficiency, preventing overheating deformation, and reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

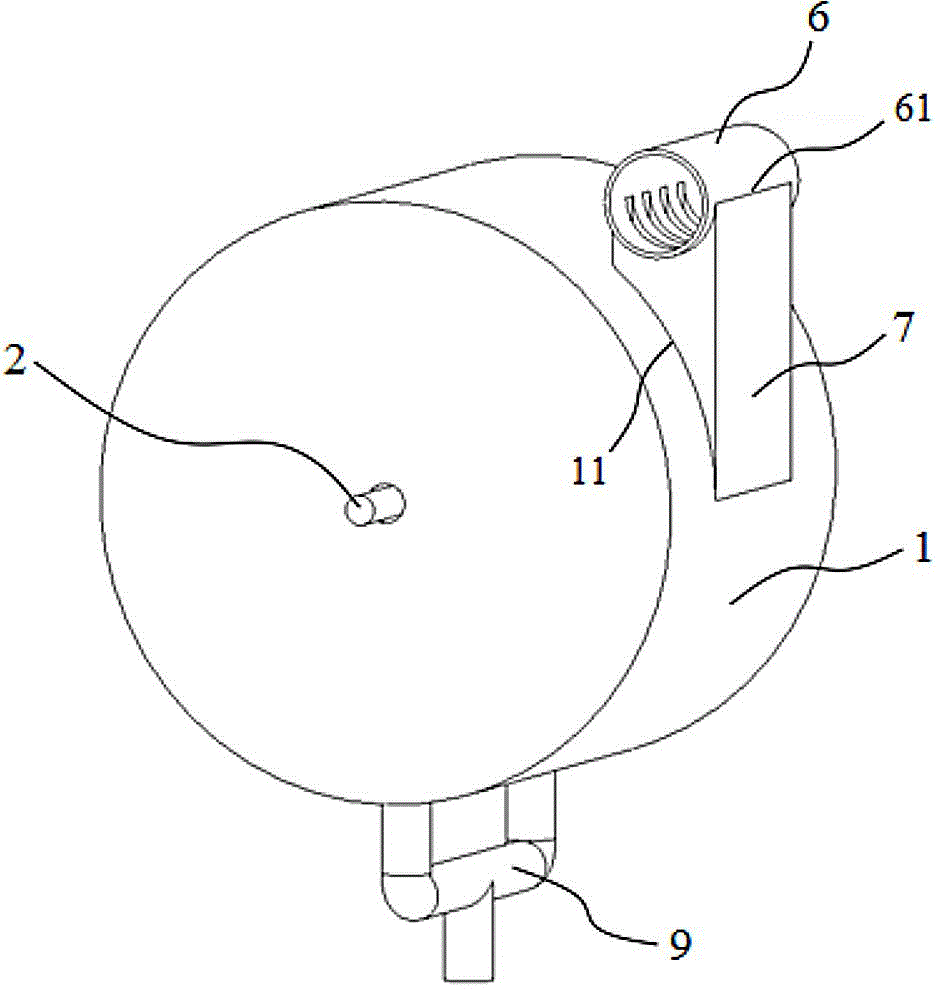

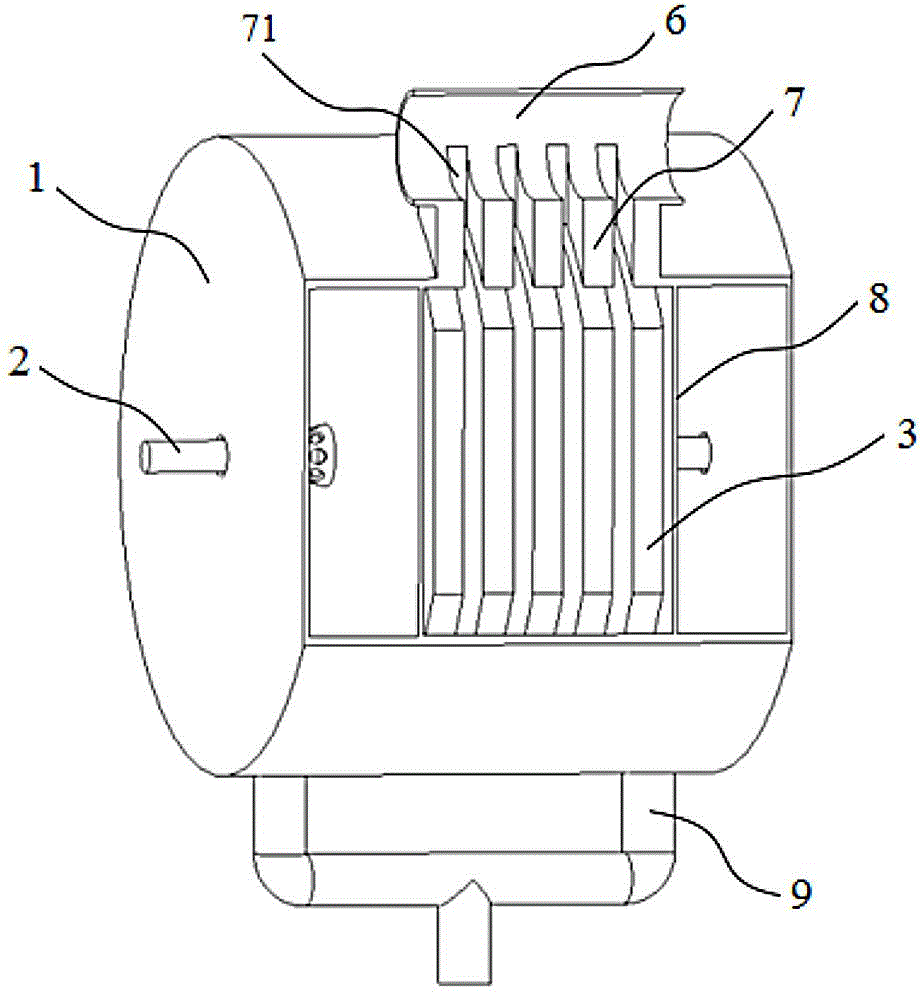

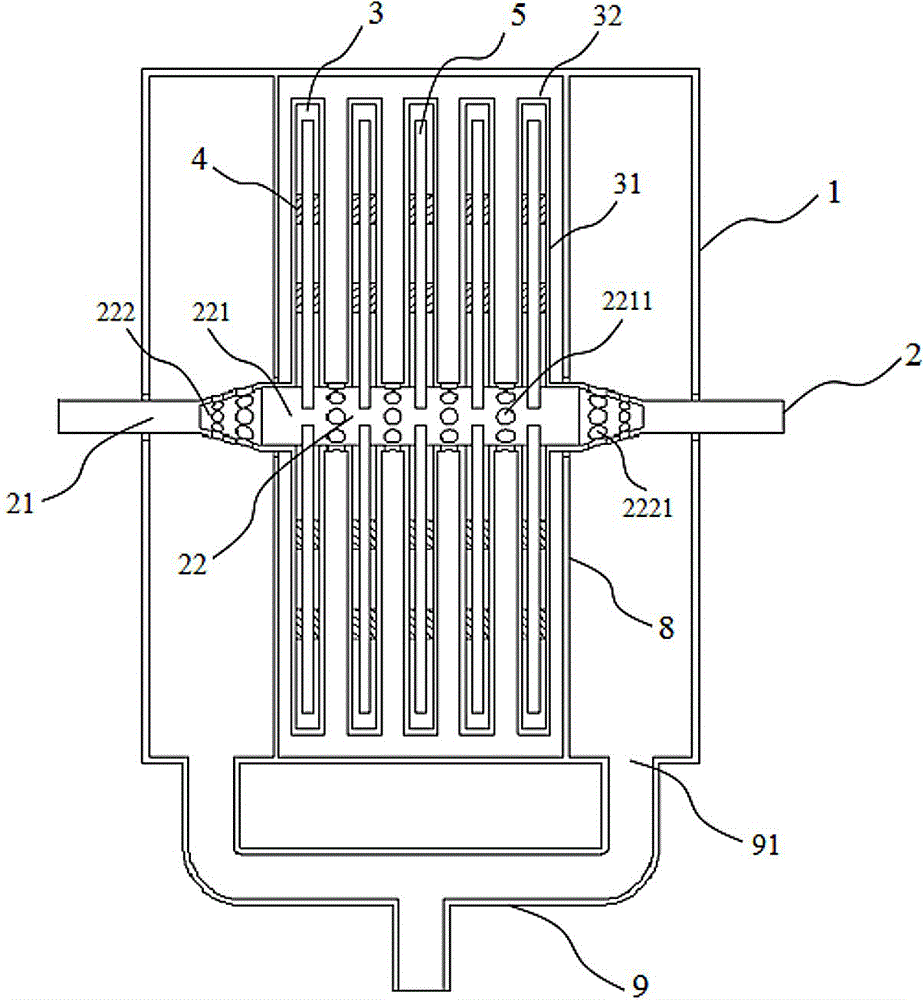

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention is a bladeless turbine engine, which includes a cylinder 1, a rotating shaft 2, a plurality of cavity disc bodies 3, a plurality of pulleys 4, a plurality of heat pipes 5, a steam inlet pipe 6, and a nozzle group 7 , clapboard 8, exhaust pipe 9.

[0023] The cylinder 1 is a hollow cylinder placed horizontally, and a variable-section rotating shaft 2 that runs through the two bottom surfaces of the cylinder is installed on the center line of the cylinder 1. One side of the upper half of the cylinder 1 is provided with several shafts perpendicular to the rotating shaft 2. Rectangular steam inlet group 11; the two ends of the rotating shaft 2 are small-diameter solid shafts 21, the solid shaft 21 extends from the inner cavity of the cylinder 1 to the outside of the cylinder 1, and a steam seal is set at the place where the solid shaft 21 leads out of the cylinder 1 (not shown in the fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com