Sealed urea heating pipe

A heating tube, sealed technology, applied in the field of components of automobile exhaust gas treatment system, can solve the problems of unsatisfactory heating effect, signal unable to be recognized and captured by computer, SCR exhaust gas treatment system unable to operate normally, etc. , the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

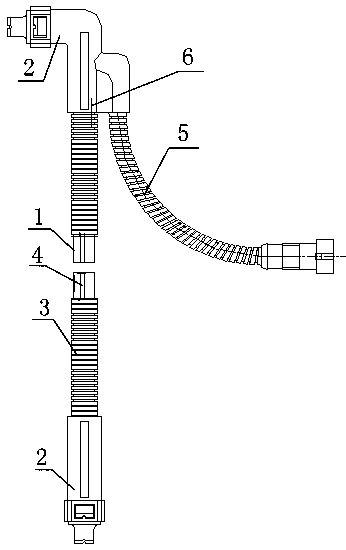

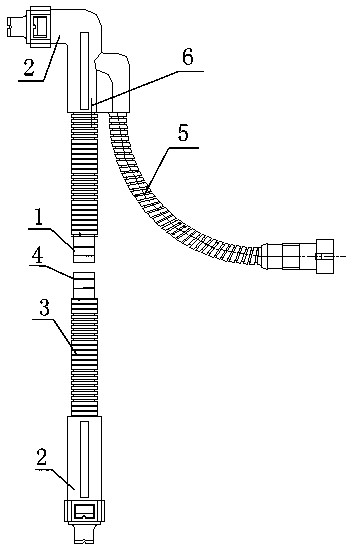

[0022] The present invention as figure 1 , 2 shown.

[0023] A sealed urea heating pipe, comprising a urea liquid return pipe 1, the two ends of the urea liquid return pipe 1 are respectively provided with quick-plug joints 2, and the outside of the urea liquid return pipe 1 is provided with a bellows 2, and the urea liquid return pipe 1 is provided with a bellows 2. A heating wire or a heating belt 4 is arranged outside the liquid return pipe 1, and the heating wire or heating tape 4 wraps the urea liquid return pipe 1 and solidifies the quick-plug joints 2 at both ends, and leads out the plug 5 through the side wall of the quick-plug joint 2 wiring;

[0024] The push-in connector 2 and the urea return pipe 1 are plastic-sealed and cured at one time to form a whole;

[0025] The urea return pipe 1 is provided with a heating wire or a heating belt 4, and the heating wire or heating belt 4 is placed in the center through the push-in connectors 2 at both ends in the urea retu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com