Electronic component test equipment

A technology of electronic components and testing equipment, applied in the field of electronic component testing equipment, can solve the problems of cost, reduction, long pre-cooling operation time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

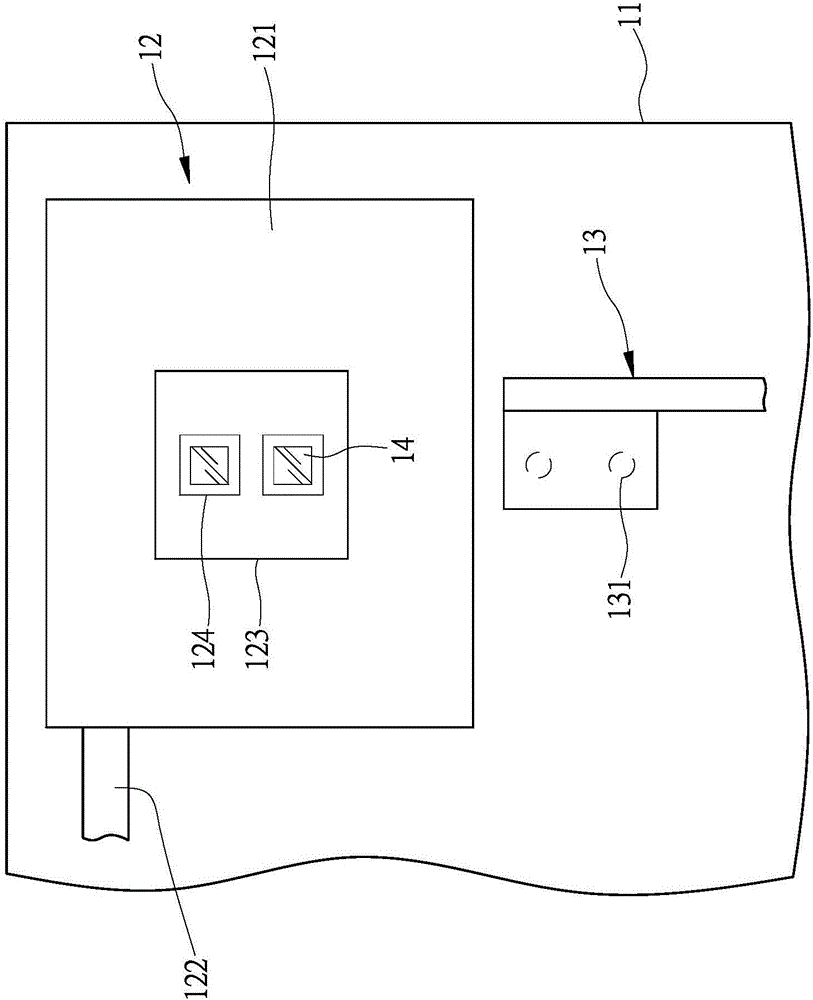

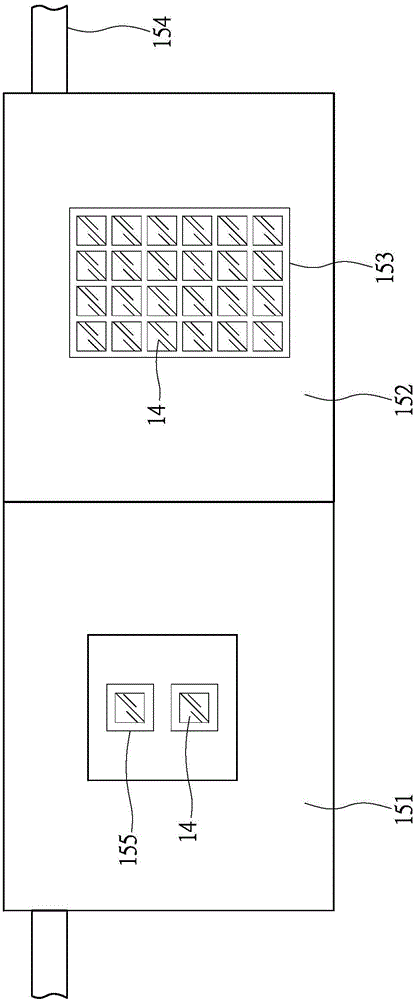

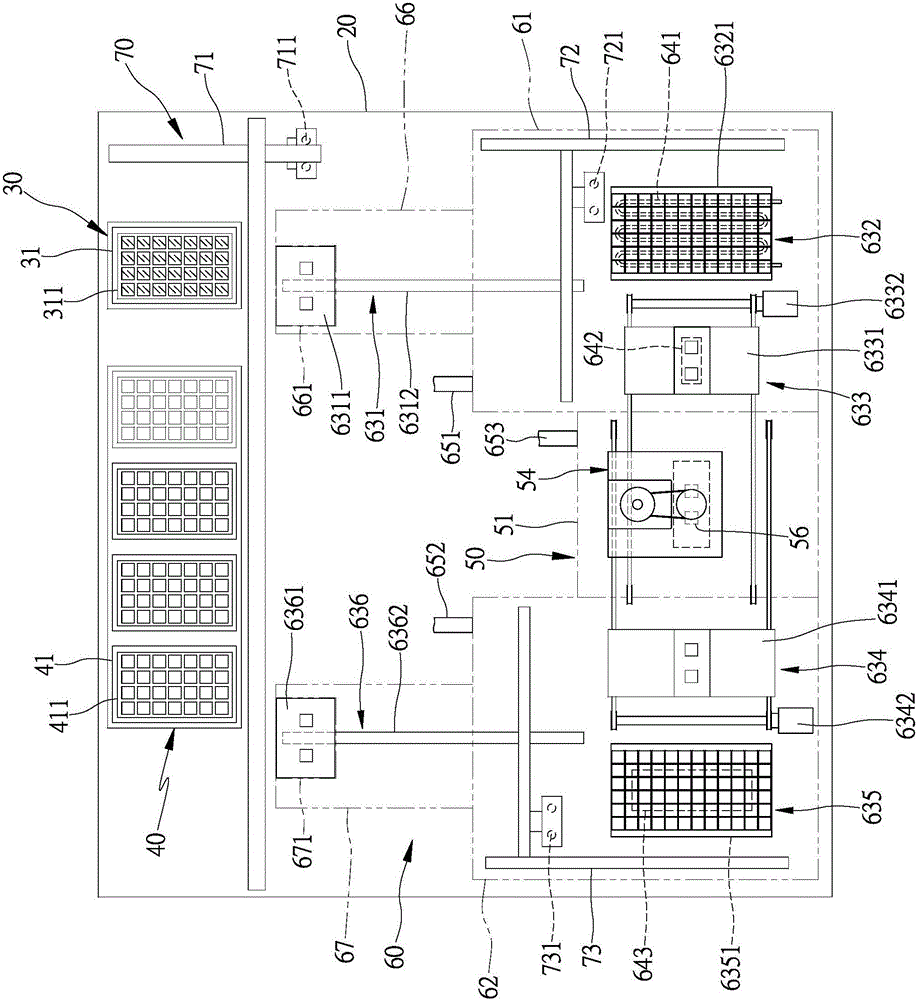

[0041] In order to make your examiner further understand the present invention, hereby give a preferred embodiment and cooperate with the drawings, as follows in detail:

[0042] see image 3 , Figure 4 , the electronic component testing equipment of the present invention comprises machine platform 20, feeding device 30, receiving device 40, testing device 50, environment control device 60, moving device 70 and central control device (not shown), this feeding device 30 It is assembled on the machine table 20, and is provided with at least one feeding mechanism for accommodating at least one electronic component to be tested. In this embodiment, a feeding mechanism 31 with a feeding tray 311 is provided, and for The material tray 311 accommodates a plurality of electronic components to be tested; the receiving device 40 is assembled on the machine platform 20, and is provided with at least one receiving mechanism for accommodating at least one electronic component that has be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com