Low temperature test device

A low-temperature test and low-temperature tank technology, which is used in the testing of measuring devices, machine/structural components, and the use of stable tension/pressure to test the strength of materials, etc. The effect of high test automation, high mechanical properties and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0013] A preferred embodiment is given below:

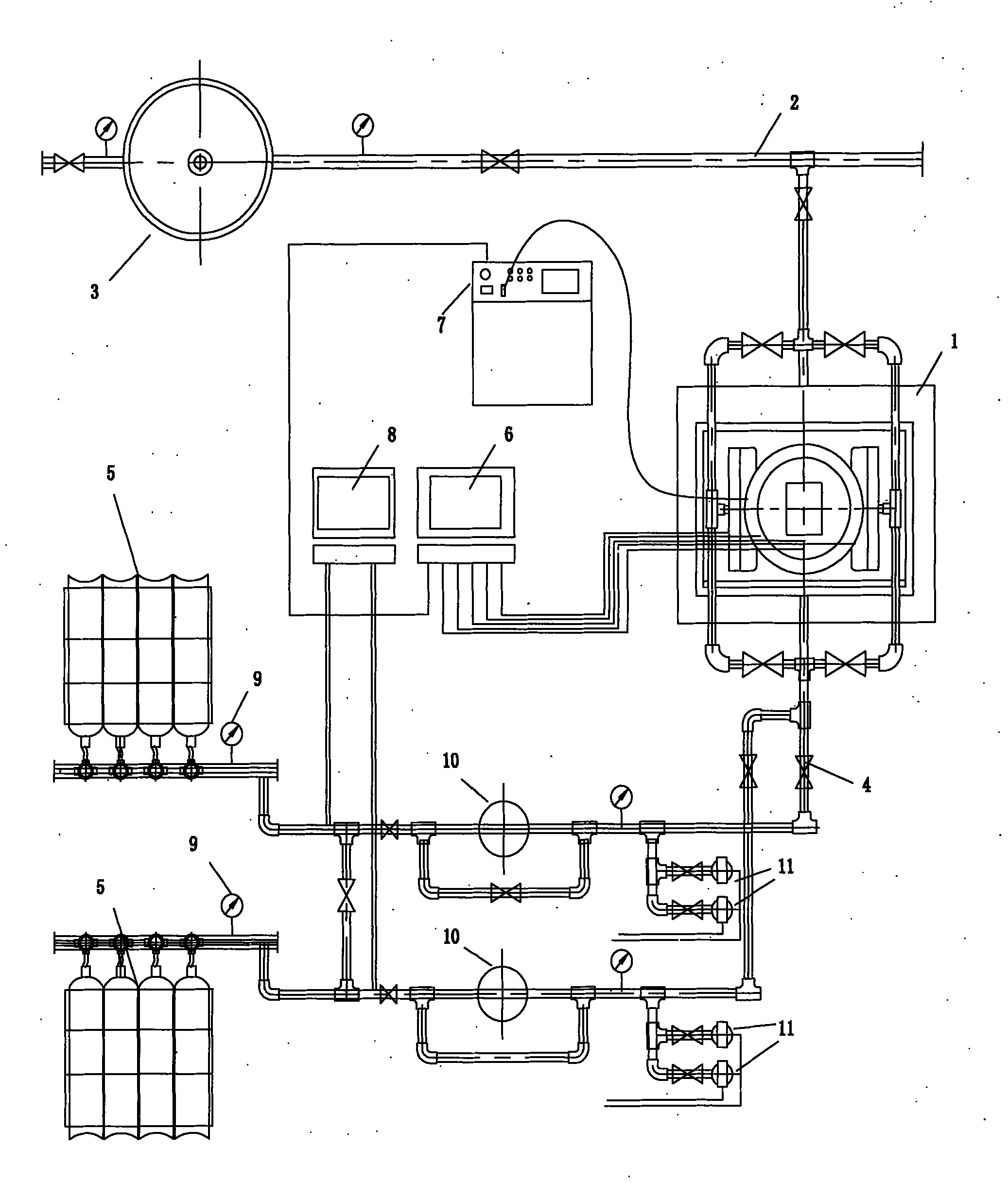

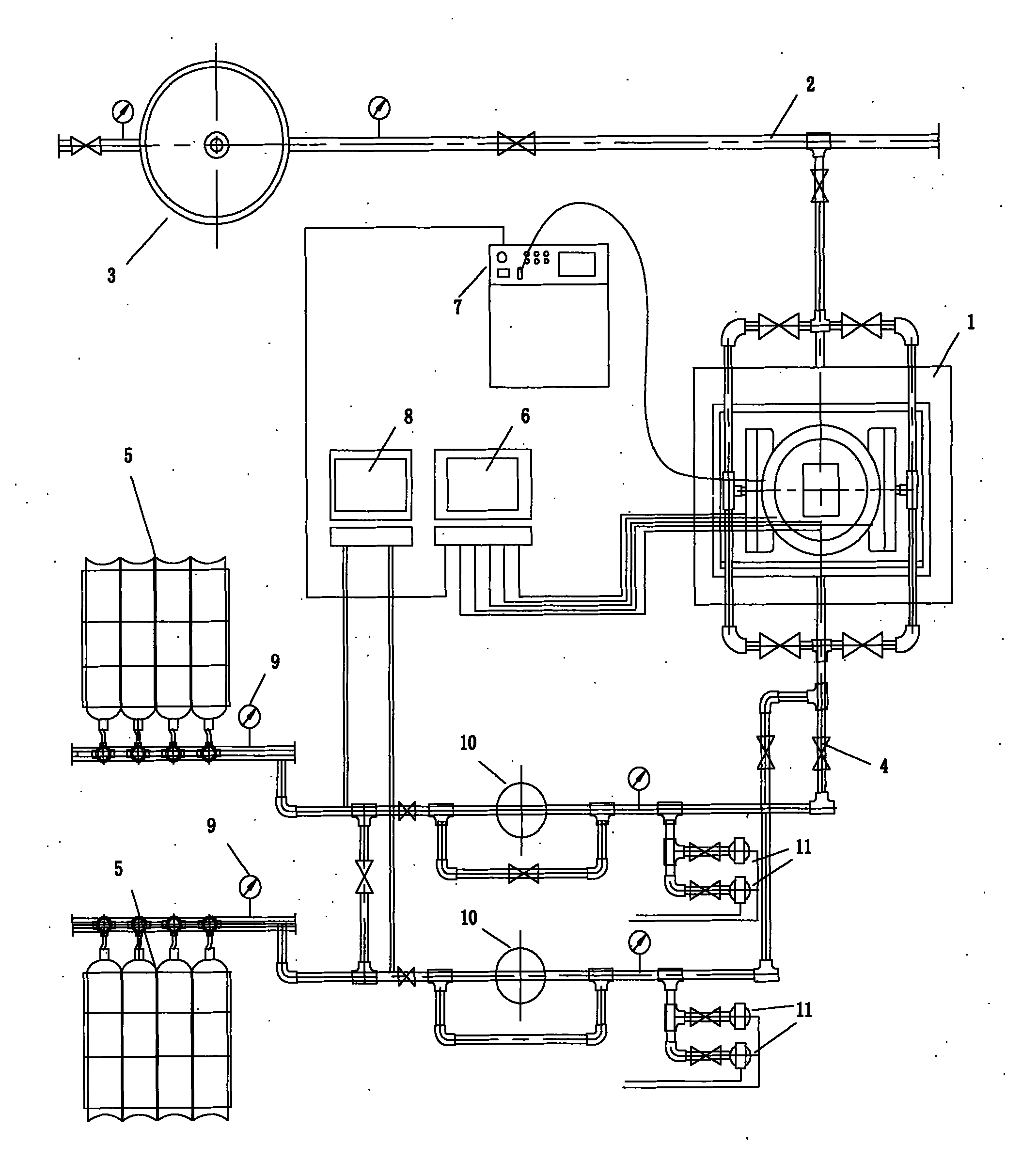

[0014] A low-temperature test device, comprising a low-temperature tank 1, one end of the low-temperature tank 1 is connected to a liquid nitrogen storage tank 3 through a pipeline 2, and one end is connected to a nitrogen group bottle 5 through a pipeline 4, and the low-temperature tank 1 is also connected to each other through lines There are electrical control unit 6 and helium leak detector 7.

[0015] A gas source control unit 8 , a nitrogen pressure gauge 9 , a nitrogen booster pump 10 and a pressure transmitter 11 are arranged on the pipeline 4 between the cryogenic tank 1 and the nitrogen group bottle 5 .

[0016] A low-temperature test device of the present invention understands and determines the material and pre-processing process of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com