Method for oxidizing and absorbing As(III) in water by water hyacinth root

A technology of water hyacinth and root, which is applied in the direction of adsorbed water/sewage treatment, etc., can solve the problems of deterioration of ecological environment and unfavorable industrialization operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Ordinary tap water is mixed with sodium arsenite to make the concentration of As(III) reach 150μg / L, hereinafter referred to as polluted water.

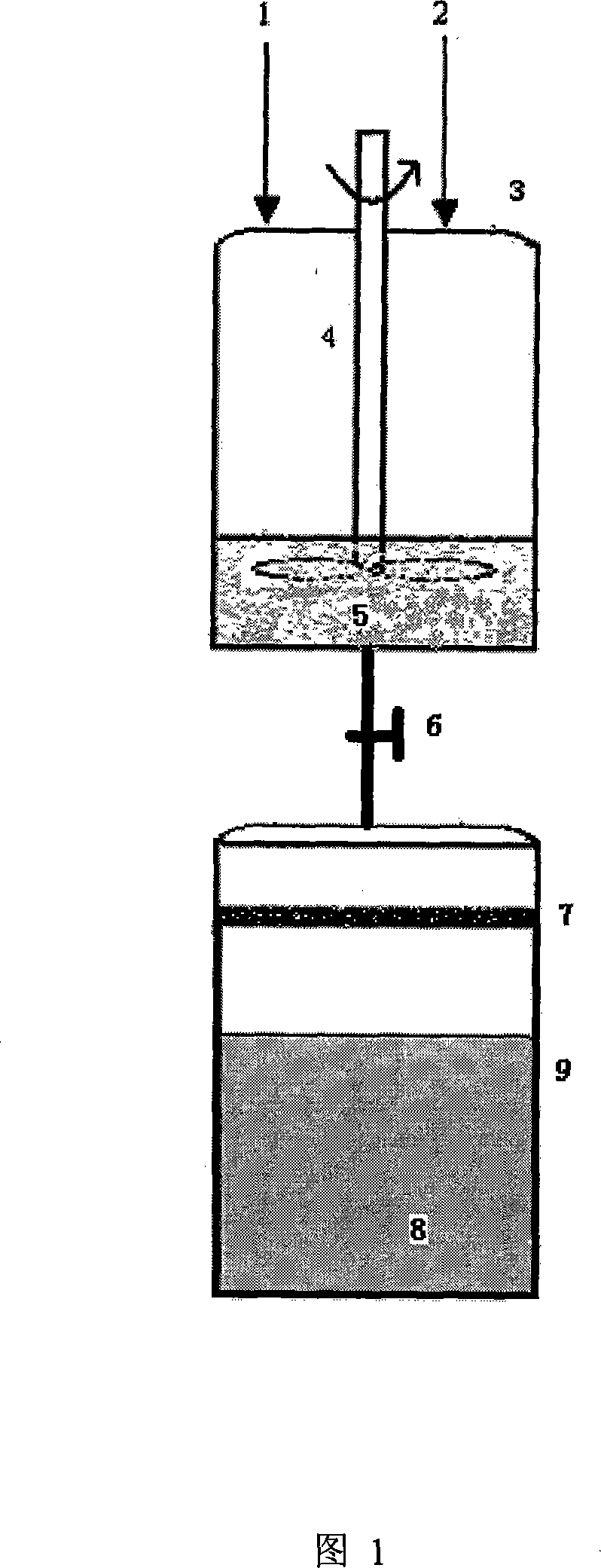

[0036]Treatment method: collect water hyacinth, wash and dry, intercept its root hair, and crush it to a powder with a length of no more than 0.5 cm; combine the contaminated water 1 and water water hyacinth root powder 2 into the In the premix tank 3, the usage amount of water hyacinth hyacinth root powder and the mass ratio of As(III) polluted water body is 1: 100. In the premix tank, a mechanical stirring device 4 is used to intermittently stir mechanically for about 8 hours. 5-10 minutes for 36 hours. Then the pre-mixed water and root hair mixture 5 are passed through the 200 mesh 7 through the pipeline 6 with a valve, and the filtered water 8 enters the collecting tank 9 . The above treatments were all carried out at ambient temperature.

[0037] Ordinary tap water contains As(III) up to 150μg / L. Add root hairs accordin...

Embodiment 2

[0039] Common tap water was mixed with sodium arsenite to make the concentration of As(III) up to 60 μg / L, in order to investigate the treatment effect of reducing the amount of root hairs of the plant under the condition of lower arsenic concentration.

[0040] Processing method is with embodiment 1.

[0041] Ordinary tap water contains As(III) up to 60μg / L. Add water hyacinth root root powder according to 1 / 250 of the water mass, stir intermittently for 5-10 minutes every 8 hours, and continue to balance for 36 hours. After filtering through sand tanks and purifying The concentration of As(III) in the water was 12.8μg / L, the removal rate was 79%, and As(III) was converted into As(V).

Embodiment 3

[0043] Ordinary tap water was mixed with sodium arsenite to make the concentration of As(III) up to 30 μg / L, in order to investigate the treatment effect of reducing the amount of root hairs of the plant under the condition of lower arsenic concentration.

[0044] Processing method is with embodiment 1.

[0045] Ordinary tap water contains As(III) up to 30μg / L. Add water hyacinth root root powder according to 1 / 250 of the water quality, stir intermittently for 5-10 minutes every 8 hours, and continue to balance for 36 hours. After filtering through sand tanks and purifying The concentration of As(III) in the water was 7.2μg / L, the removal rate was 76%, and As(III) was converted into As(V).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com