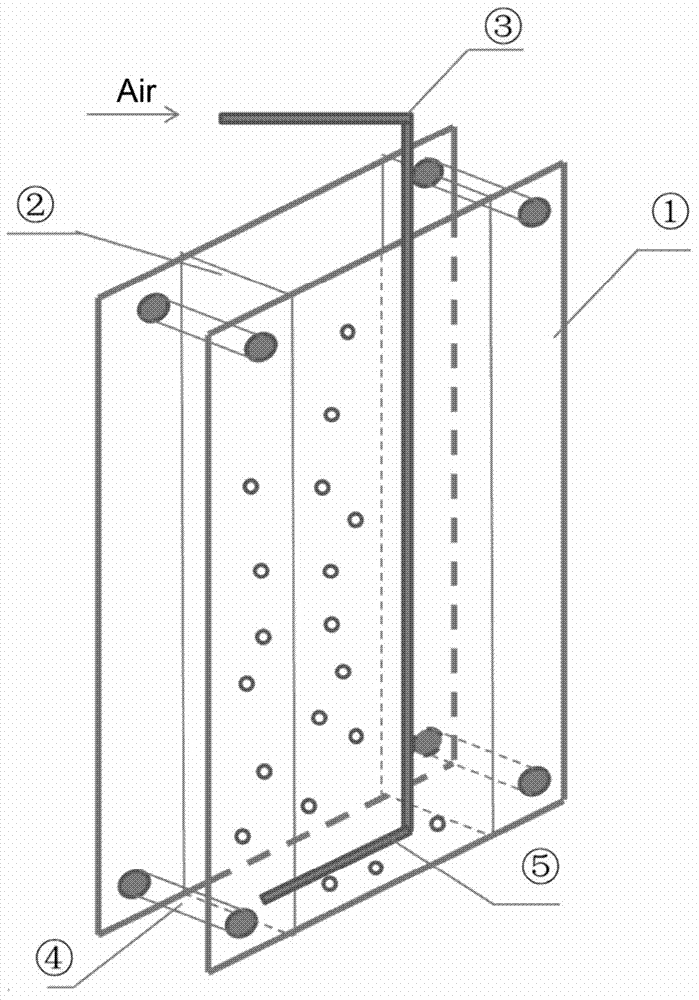

Optical path variable plate-type microalgae culture reactor

A culture reactor and microalgae culture technology, applied in the field of variable optical path plate type microalgae cultivation reactors, can solve the problem of not having to change the optical path, and achieve the effects of satisfying cell growth, shortening the optical path, and high biomass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

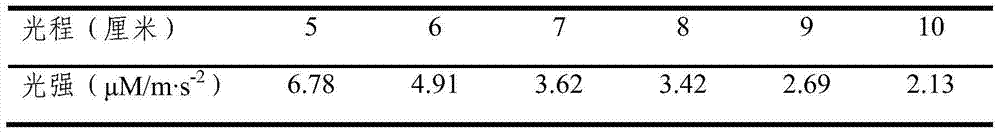

[0024] Isochrysis Zhanjiang was cultured at an initial inoculation density of 10 million cells per milliliter. The medium was a general-purpose F / 2 medium, the carbon dioxide concentration was 1.4%, and the incident light intensity was 95 μM / m·s -2 . By adjusting the ball screw ④, the transmitted light intensity of the system under the same biomass and different optical paths was measured, see Table 1. The results showed that by adjusting the light path, the utilization of light energy in the culture system was changed.

[0025] Table 1. Transmitted light intensity at different optical paths

[0026]

Embodiment 2

[0028] Isochrysis Zhanjiang was cultured at an initial inoculation density of 10 million cells per milliliter. The culture medium was general F / 2 medium with a carbon dioxide concentration of 1.4% and an initial optical path of 5 cm. After growing to 15 million cells per milliliter, the The optical path of the system is adjusted to 7 cm, the concentration of carbon dioxide is adjusted to 2.1%, and water is added to increase the volume by 40%. The expansion to the production scale is completed in the same device.

Embodiment 3

[0030] Isochrysis zhanjiang was cultured at an initial inoculation density of 10 million cells per milliliter. Under the same conditions as other growth conditions, the cells in a 10 cm light path reactor grew to 30 million cells per milliliter, which was affected by the self-shielding effect, that is The stable phase is reached; and using the reactor of the present invention, under the condition of a light path of 5 cm, the final growth reaches 78 million cells per milliliter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com