Turbo shaft engine test bench for aviation

A turboshaft engine and test bench technology, which is applied in the direction of engine testing, machine/structural component testing, and measuring devices, can solve problems such as poor reliability and inability to guarantee rigidity, and achieve small footprint, stable transmission, and simplified transmission Institutional Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

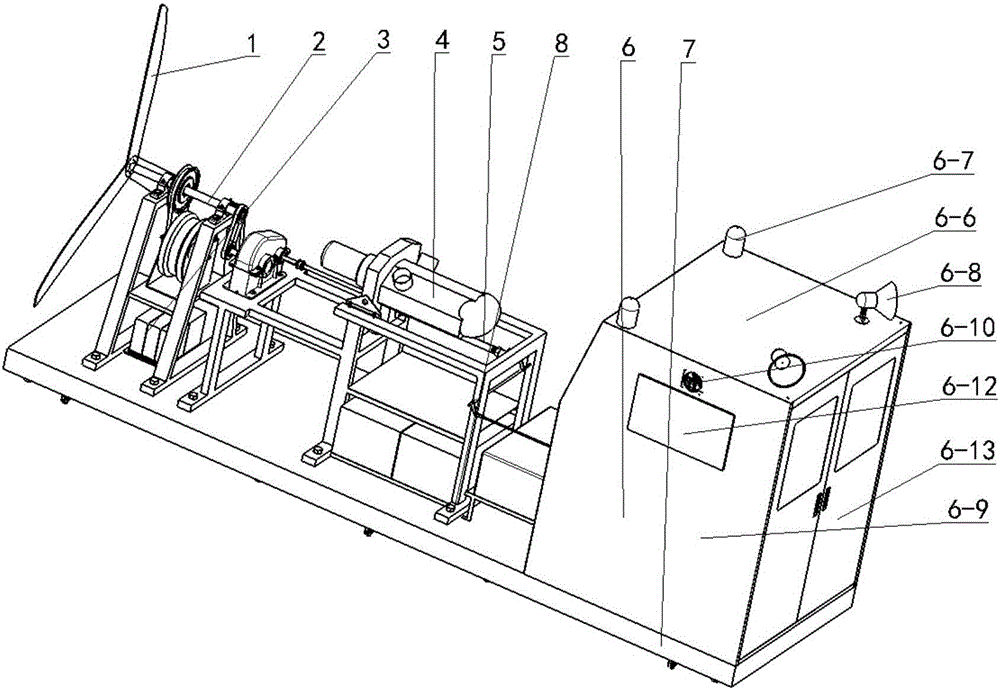

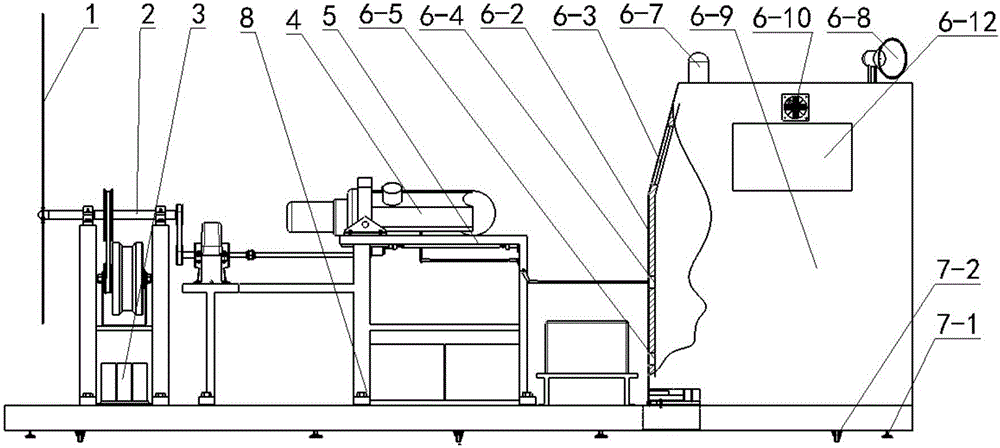

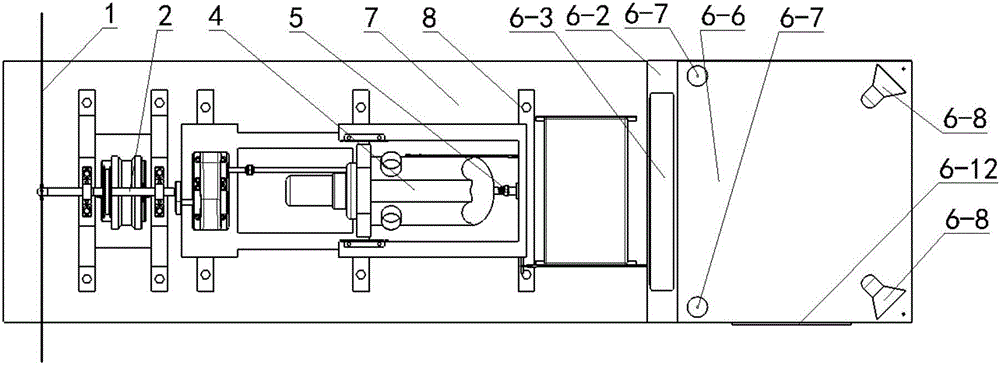

[0096] Such as Figure 1 ~ Figure 4 As shown, the present invention includes a propeller 1, a drive system 2, a control system 3, an engine 4, a support structure 5, a control room 6 and a base 7;

[0097] Such as Figure 1 ~ Figure 4 , Figure 8 and Figure 9As shown, the drive system 2 includes a frame 2-1, a motor mounting plate 2-2 is welded on the frame 2-1, a motor bracket 2-3 is welded on the motor mounting plate 2-2, and a motor mounting plate 2-3 is welded on the frame 2-1. The right side of 2-1 is also provided with the third column 5-3 shared with support structure 5 and reducer support plate 5-9, motor 2-4 is installed on motor support 2-3, on frame 2-1 The top is equipped with a first bearing seat 2-10 and a second bearing seat 2-16, and a ball bearing 2-18 is installed in the first bearing seat 2-10 and the second bearing seat 2-16, and two ball bearings 2 Main shaft 2-11 is installed in -18, the fourth pulley 2-13 is installed on the main shaft 2-11, the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com