Full-automatic loading and unloading positioning device for bowl cutter

A positioning device, fully automatic technology, applied in the direction of positioning device, clamping, support, etc., can solve the problems of inability to clamp and position the gasket block, and there is no mechanized installation method for the gasket block, and achieve the effect of improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

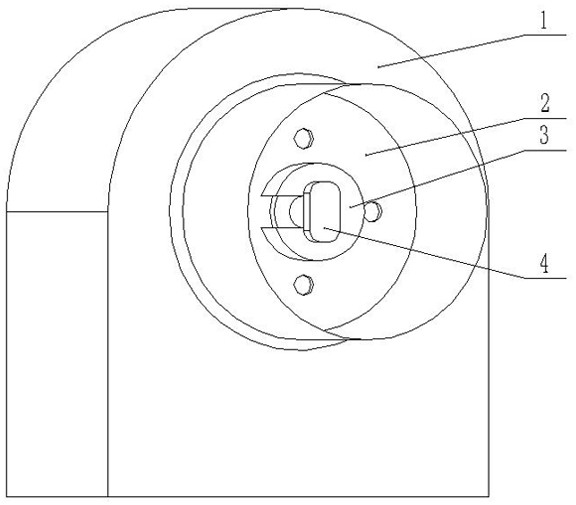

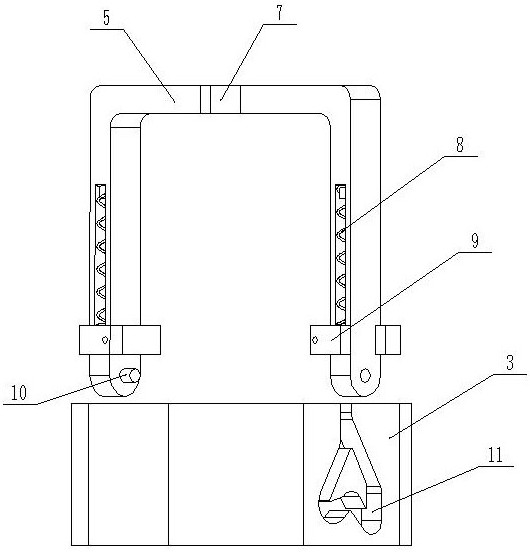

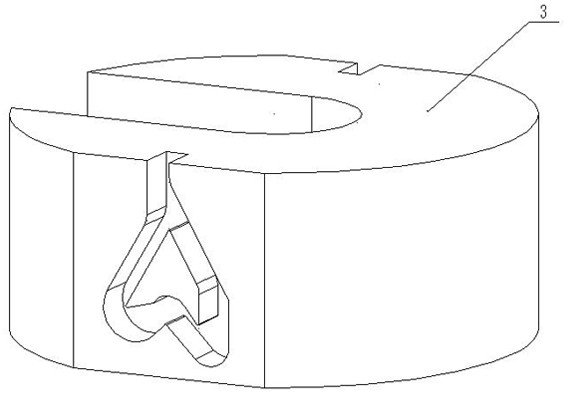

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] Such as Figure 2-Figure 4 As shown, a fully automatic loading and unloading positioning device for bowl knives in an embodiment of the present invention includes a clamping frame 5 and a spacer block 3. Support arms are provided on both sides of the clamping frame 5, and the two support arms are connected by a beam. , the support arm is provided with an elastic piece 9, and the support arm is provided with a movable block 9 that is slidably connected along the length direction of the support arm. The member 9 is configured in a compressed state, ie pre-compressed. This creates greater clamping force.

[0022] Both sides of the spacer block 3 are provided with side grooves 11, and a channel for the sliding of the protrusion 10 is provided in the side groove 11. A second angle 15 bent upward is provided in the channel. When the clamping frame 5 moves downward, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com