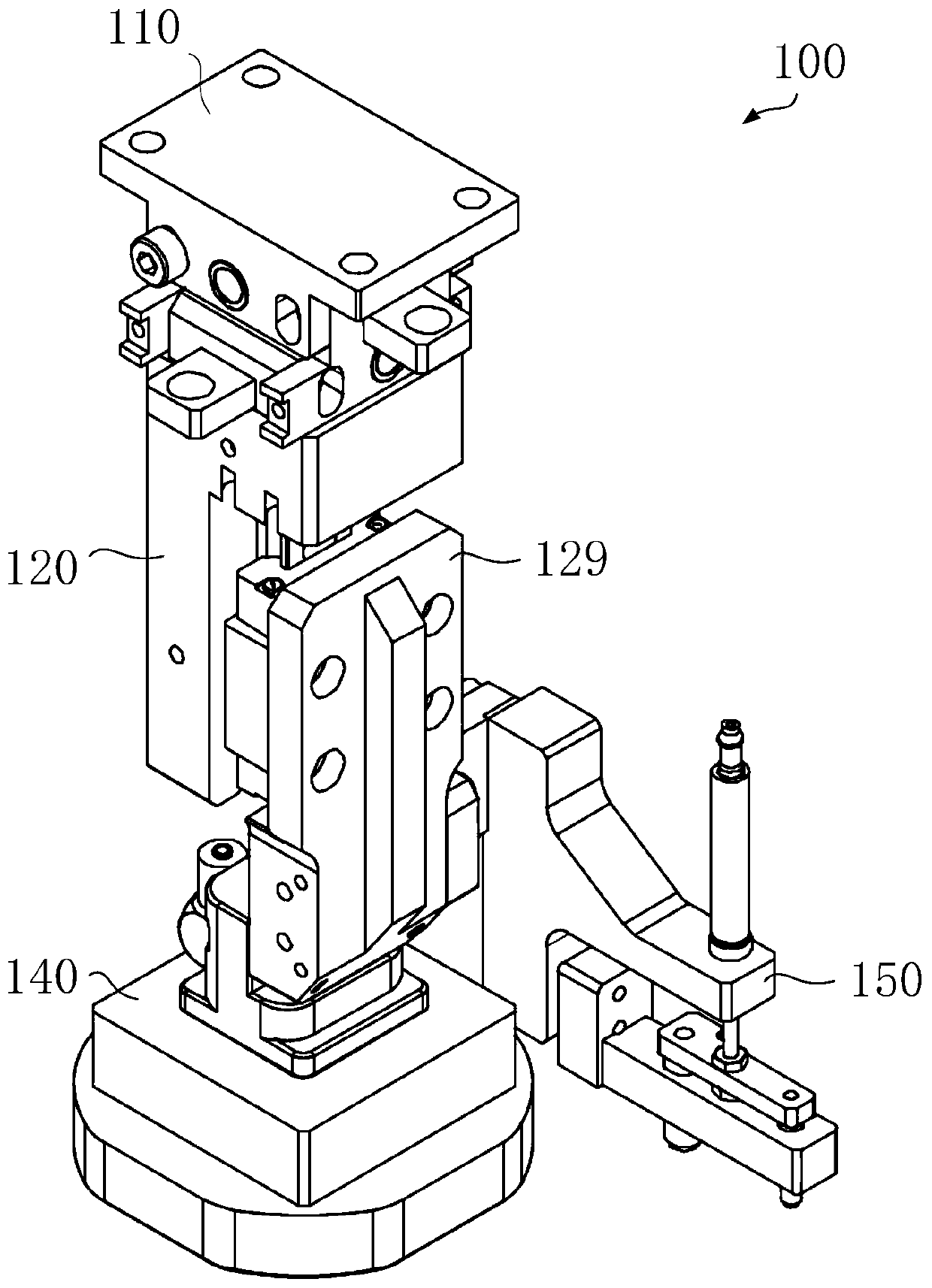

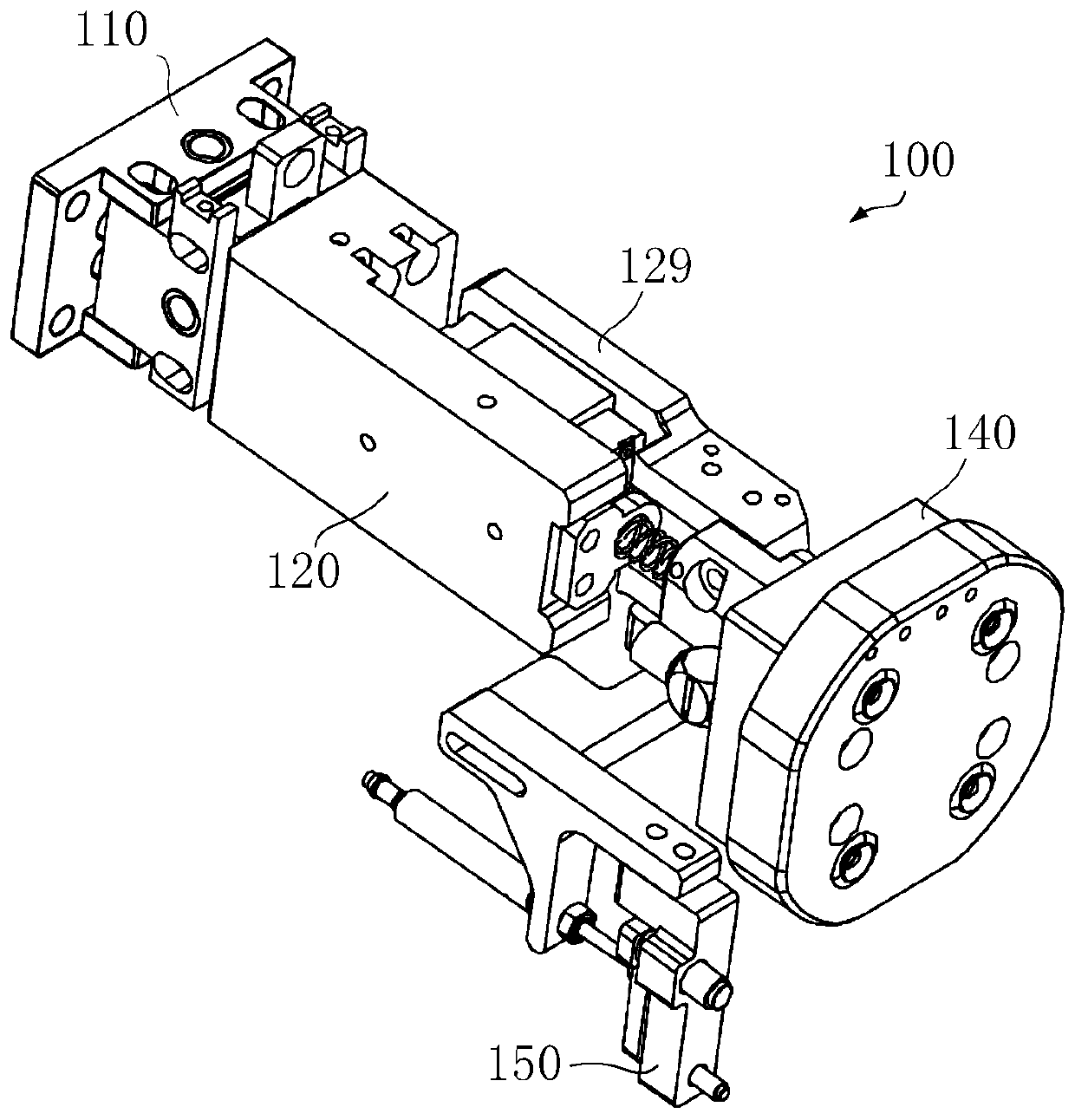

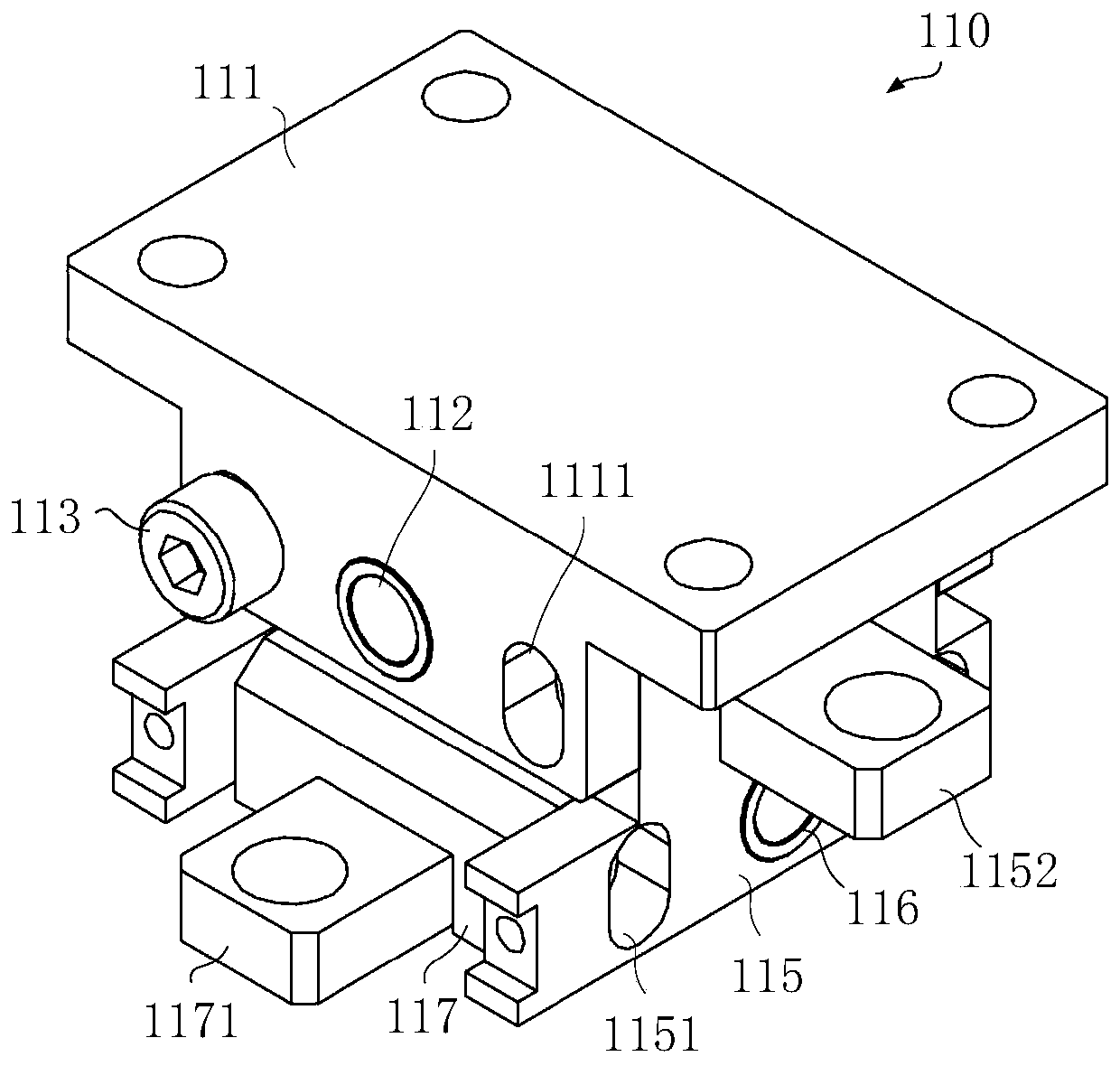

Pick-up mechanism for workpiece loading and unloading

A workpiece and workpiece picking technology is applied in the field of picking mechanisms for workpiece loading and unloading, which can solve the problems of low efficiency, high cost, and complicated control of continuous picking of multiple workpieces, so as to achieve an efficient and accurate picking process, ingenious structure, and continuous clamping force. adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below with reference to the accompanying drawings. The foregoing and other objectives, features, aspects and advantages of the present invention will become more apparent, so that those skilled in the art can implement them with reference to the text of the description. In the drawings, the shape and size may be enlarged for clarity, and the same reference numerals will be used in all the drawings to indicate the same or similar parts. In the following description, terms such as center, thickness, height, length, front, back, rear, left, right, top, bottom, upper, and lower parts are based on the orientation or positional relationship shown in the drawings. In particular, "height" corresponds to the size from top to bottom, "width" corresponds to the size from left to right, and "depth" corresponds to the size from front to back. These relative terms are for convenience of description and are generally not intende...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com