Sanitary pad fiber separation device by utilizing leading, absorbing and scraping principle

A fiber separation and sanitary napkin technology, applied in the field of sanitary napkin fiber separation, can solve the problems of fiber loss, heavy material raw materials entangled and taken away, unable to efficiently improve the absorption of fiber raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

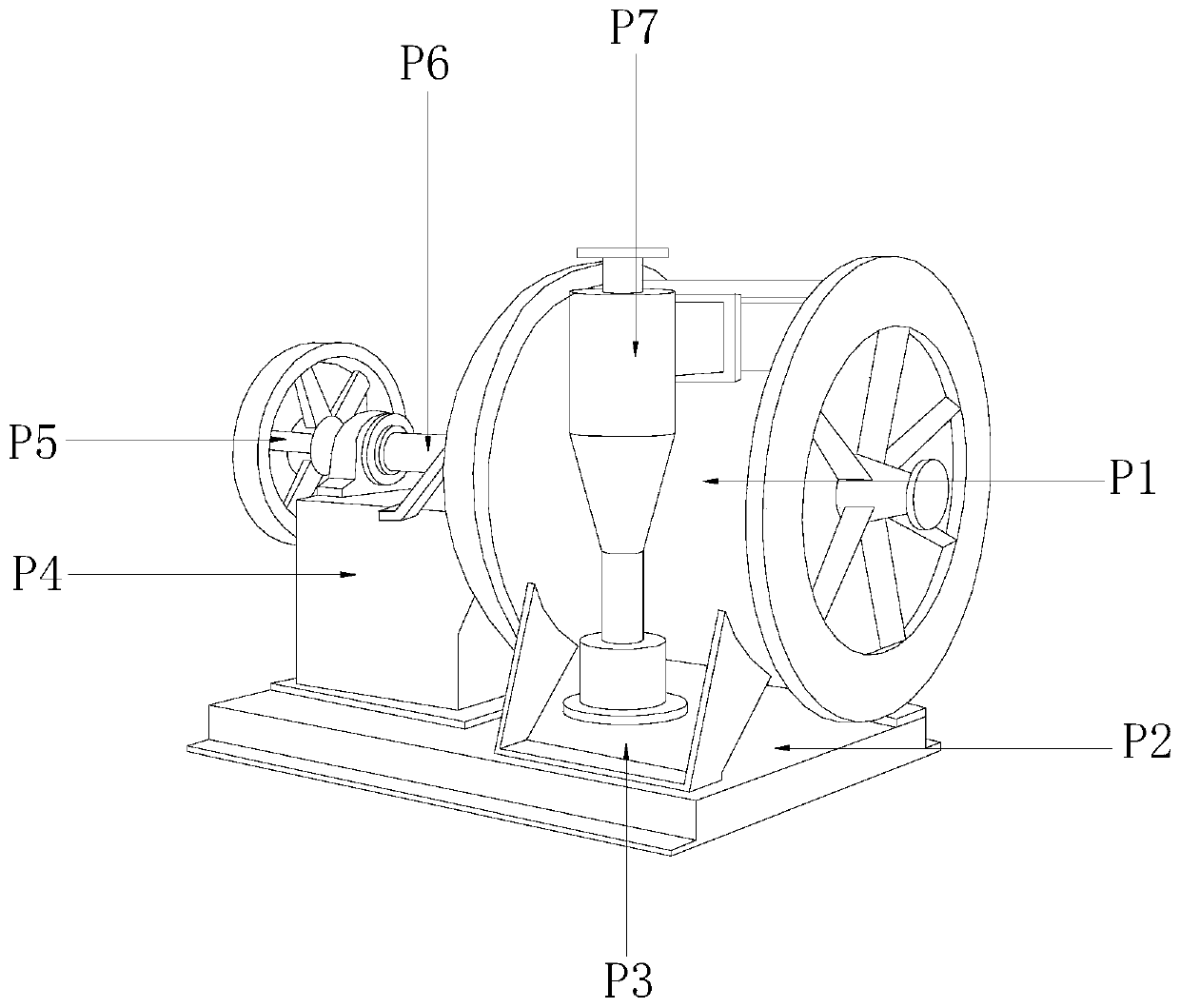

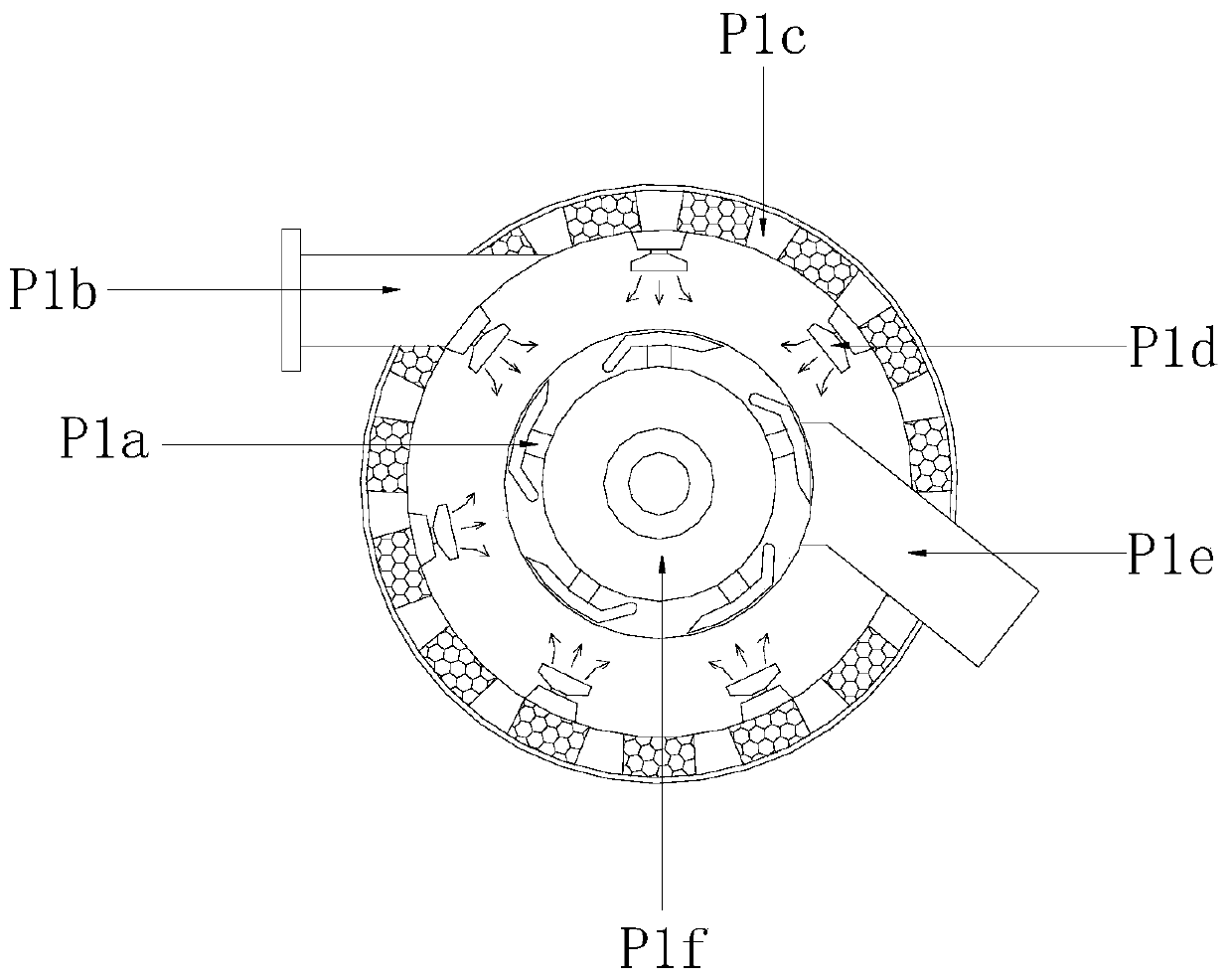

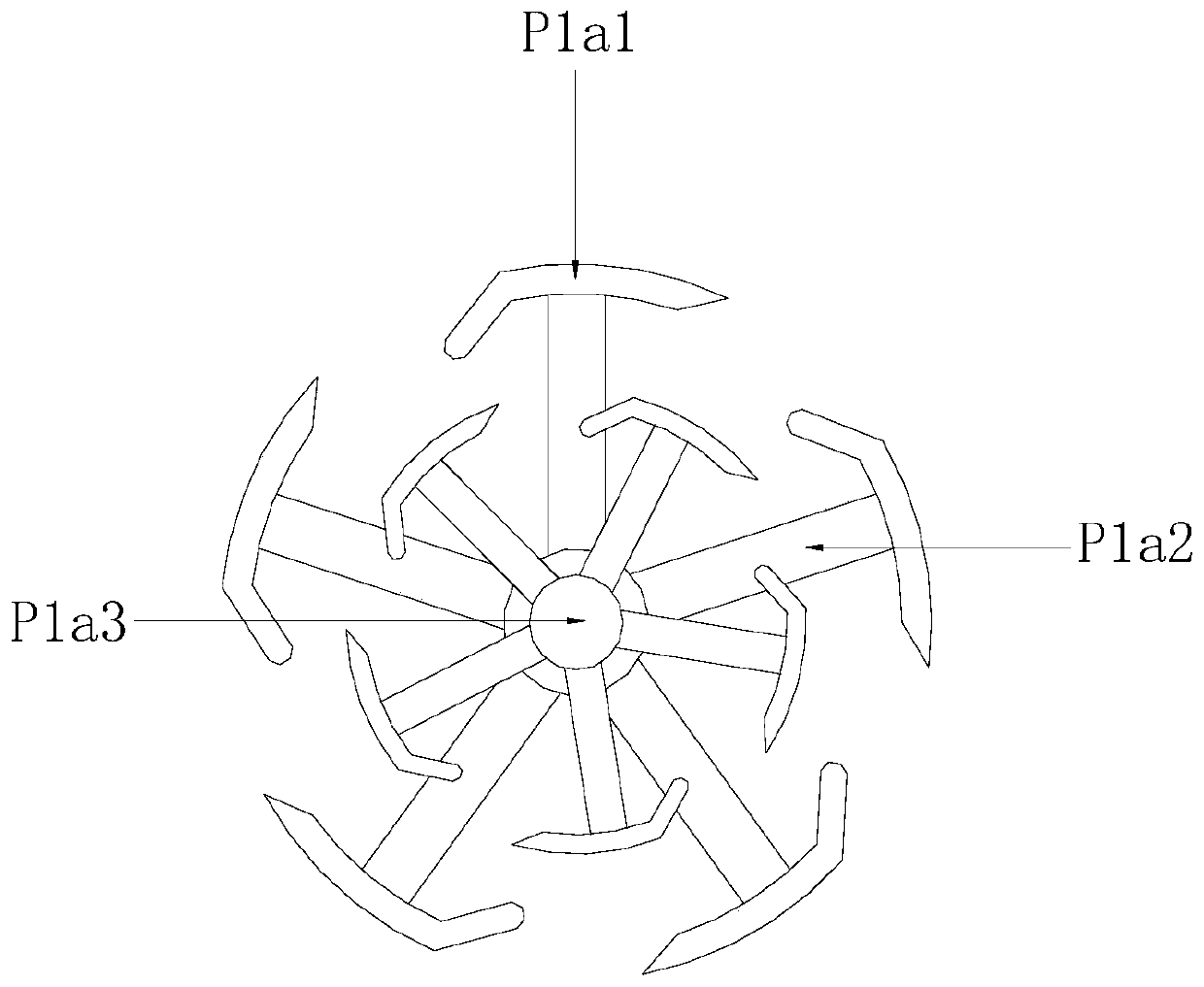

[0028] see Figure 1-Figure 6 , the present invention provides a sanitary napkin fiber separation device that adopts the principle of guiding and scraping. Its structure includes a separation chamber P1, a fixed base P2, a positioning foot P3, a control host P4, a pulley P5, a drive shaft P6, and a crushing mechanism P7. The bottom of the separation chamber P1 is fastened and installed on the top right end of the fixed base P2 through the positioning foot P3, the left end of the top of the fixed base P2 is provided with a control host P4, and the right end of the drive shaft P6 is connected through the middle of the separation chamber P1. The front end of P1 is equipped with a crushing mechanism P7, which is connected by buckling. The middle part of the pulley P5 is connected with the left end of the drive shaft P6. After the pulley P5 rotates, the drive shaft P6 drives the inside of the separation chamber P1 to perform separation processing, and then passes through The pulver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com