Triaxial truss type high-speed servo robot

A truss-type, robotic technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems affecting the efficiency of injection molding machines, long picking time, and long operating cycle, and achieve shortened sliding range, short pick-and-place cycle, The effect of quick extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

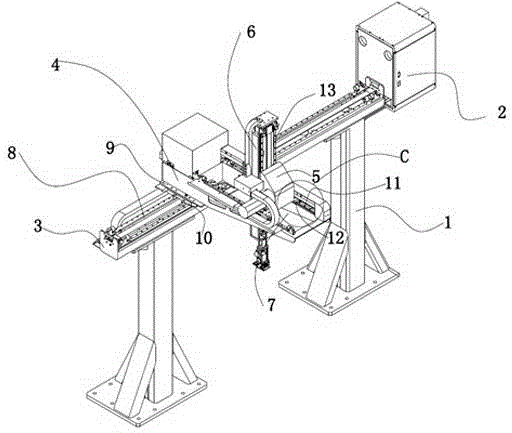

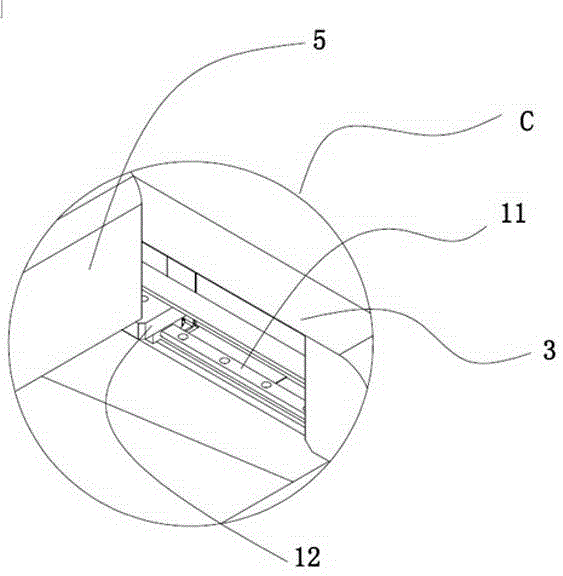

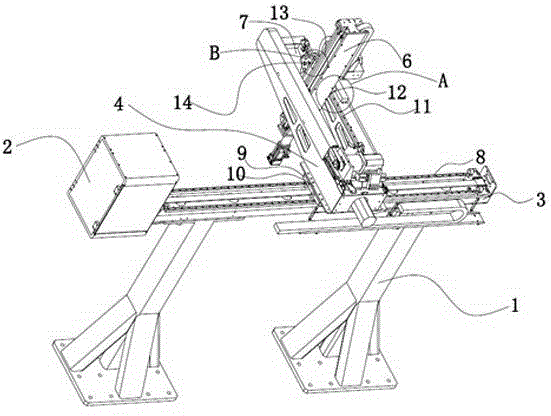

[0017] Such as figure 1 As shown, the three-axis truss type high-speed servo robot provided by the present invention includes a machine base 1, an electric control box 2, a horizontal gun barrel 3, a drawing beam 4, an arm support 5 and an arm beam 6, and the electric control box is located at One side of the horizontal barrel 3, the horizontal barrel 3 is erected on the machine base 1, the drawing beam 4 is erected on the horizontal barrel 3, and the drawing beam 4 moves back and forth along the long direction of the transverse barrel 3 Sliding, the drawing beam 4 is an inverted right-angled trapezoidal structure, and the middle of one end of the drawing beam 4 near the waist of the trapezoid is a hollow shape 7, and the arm beam 6 runs through the hollow part of the drawing beam 4 and passes through the arm bracket. 5 is erected vertically on the drawing beam 4, and the arm support 5 slides back and forth along the long direction of the drawing beam 4; at the same time, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com