Automatic lamination device of distribution transformer

A technology for distribution transformers and lamination devices, which can be used in inductor/transformer/magnet manufacturing, circuits, electrical components, etc., and can solve problems such as low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

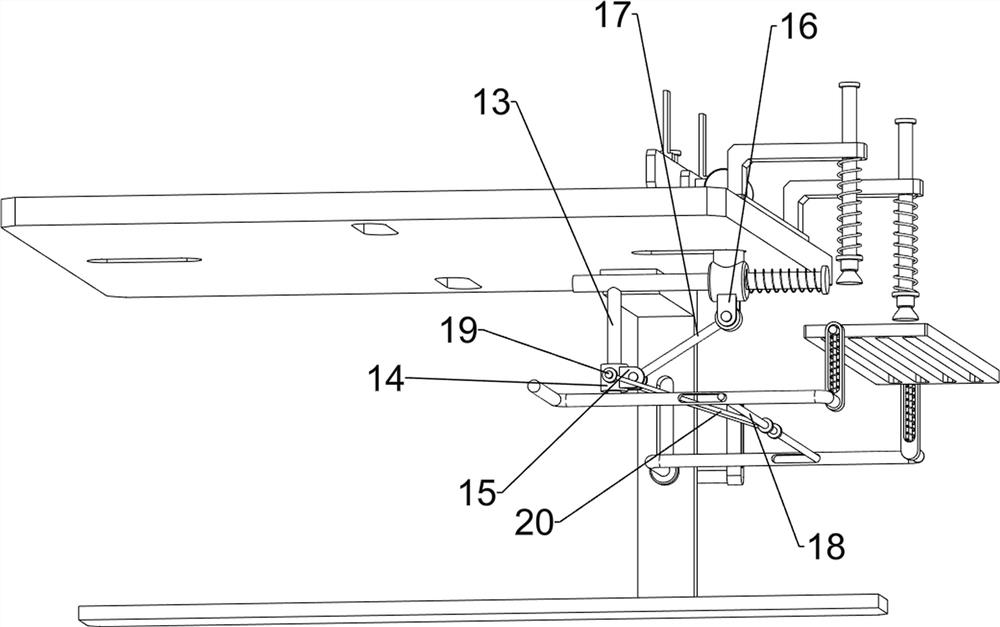

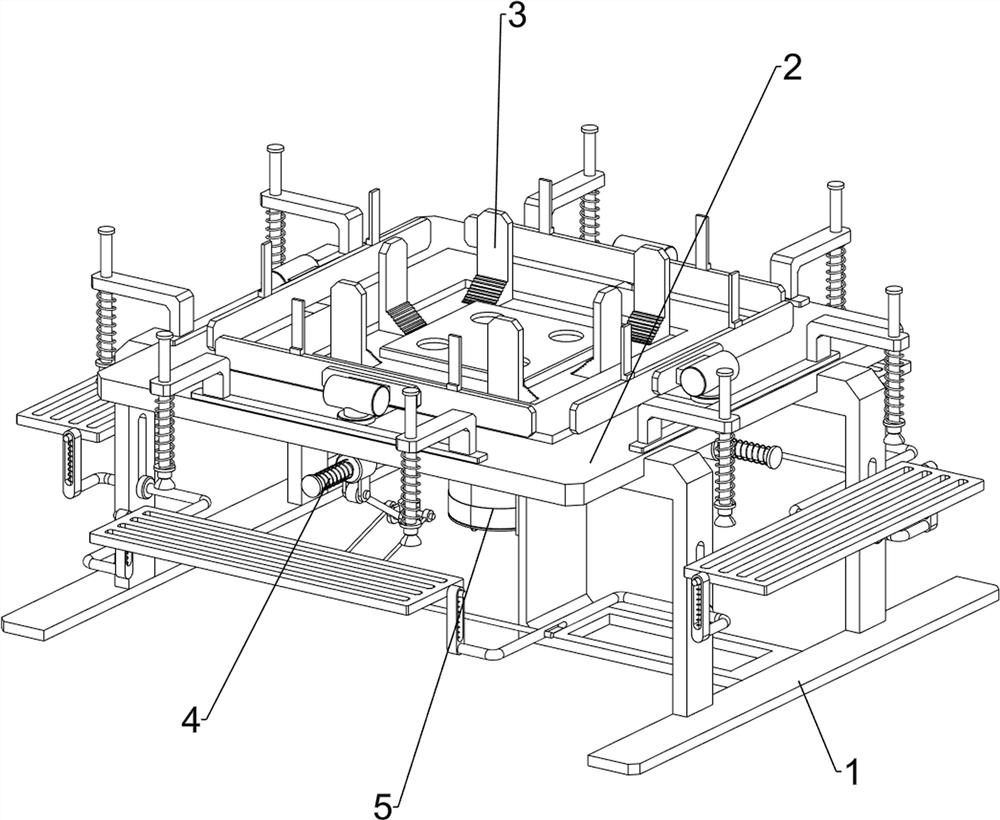

[0028] Such as figure 1 As shown, an automatic stacking device for a distribution transformer includes a bottom plate 1, a first support plate 2, a limit mechanism 3, a transmission mechanism 4 and a drive mechanism 5, the bottom plate 1 is provided with a first support plate 2, the first A limit mechanism 3 is provided on the support plate 2 , a transmission mechanism 4 is provided at the bottom of the first support plate 2 , and a drive mechanism 5 is provided on the bottom plate 1 , and the drive mechanism 5 cooperates with the transmission mechanism 4 .

[0029] When it is necessary to stack the iron cores of the distribution transformer, the staff places the iron cores on the first support plate 2 between the limit mechanism 3, and then the staff starts the driving mechanism 5, and the driving mechanism 5 rotates to drive the transmission mechanism 4 Rotate, the transmission mechanism 4 rotates and drives the limit mechanism 3 to slide towards each other to stack the iron...

Embodiment 2

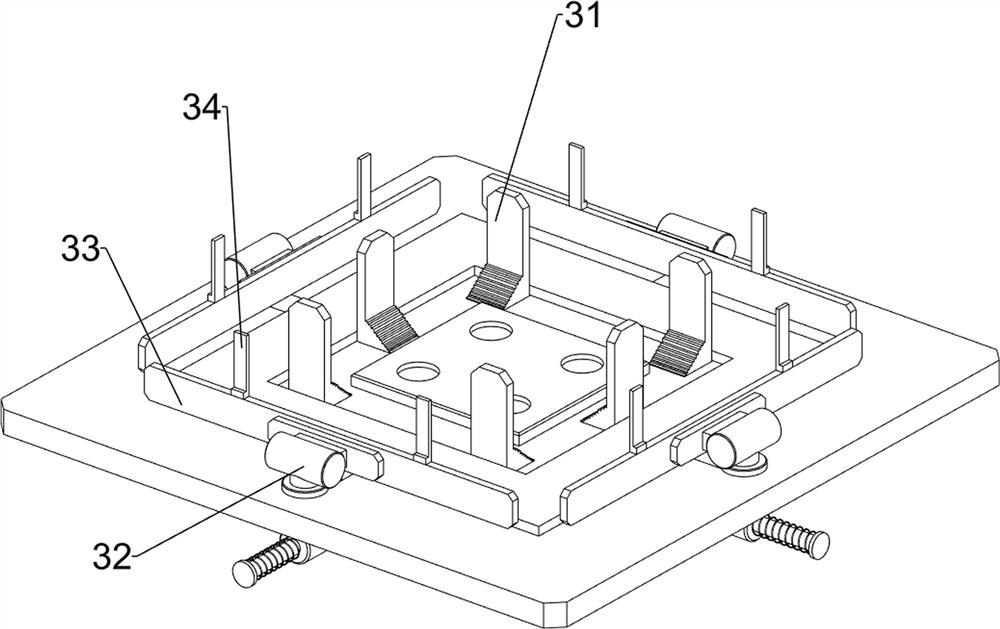

[0031] Such as figure 2 , image 3 and Figure 4 As shown, on the basis of Embodiment 1, the limit mechanism 3 includes a baffle plate 31, a first slider 32, a first fixed block 33 and a first fixed rod 34, and the middle part of the first support plate 2 is evenly spaced Six baffles 31, the four sides of the first support plate 2 are provided with chute, the first slider 32 is slidably arranged in the four chute, and the opposite side of the four first slider 32 is provided with the first fixed Block 33 , first fixing rods 34 are symmetrically arranged on the four first fixing blocks 33 .

[0032] When it is necessary to stack the iron cores of the distribution transformer, the staff places the iron cores on the first support plate 2 between the first fixing block 33 and the baffle plate 31, and then the staff starts the driving mechanism 5, and the driving mechanism 5 The rotation drives the transmission mechanism 4 to rotate, and the rotation of the transmission mechani...

Embodiment 3

[0038] Such as Figure 5 , Figure 6 and Figure 7 As shown, it also includes a second slider 6, a third fixed rod 7, a second straight chute plate 8, a first guide rod 9, a third slider 10, a second support plate 11 and a second elastic member 12 , the bottom plate 1 is provided with two inline chutes on the front and rear sides, the four inline chutes are all slidingly provided with a second slider 6, and the four second sliders 6 are all provided with a third fixing rod 7 , the two ends of the four third fixed rods 7 are provided with the second straight chute plate 8, each second straight chute plate 8 is provided with the first guide rod 9, each first guide rod 9 The third sliding block 10 is provided in a sliding manner, and a second support plate 11 is arranged between the two third sliding blocks 10 on the same side. One side of each third sliding block 10 is connected to each second straight chute. A second elastic member 12 is arranged between one side of the boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com