Full-automatic collection, smashing and compact forming combination machine for field waste crop straws

A crop straw, fully automatic technology, applied in waste fuel, animal feed, biofuel, etc., can solve the problems of insufficient water content and limited water content, and achieve the effect of reducing environmental pressure, speeding up the economy, and stabilizing the agricultural ecological balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

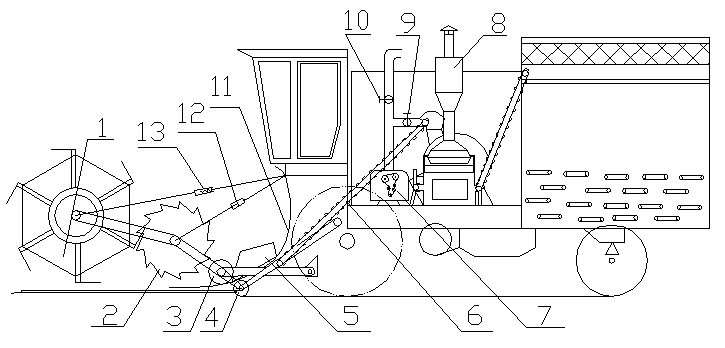

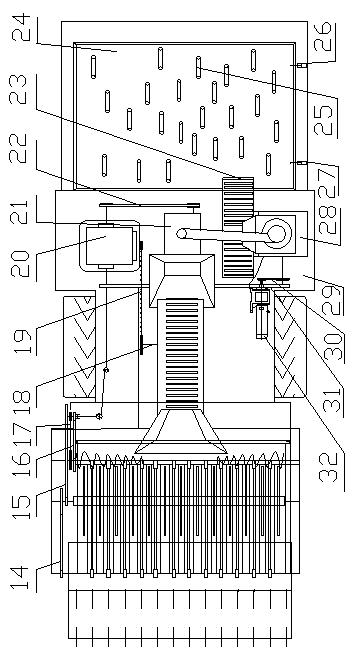

[0027] A fully automatic collecting, crushing and compacting combined machine for discarded crop straw in the field, as attached figure 1 , attached figure 2 As shown, its composition includes: a front-mounted straw automatic picking and pretreatment system with an oil cylinder, and a walking chassis integration system. The oil cylinder 12 is connected to the nail gear 1, and the nail gear is connected to the cutting saw wheel 2. The saw blade wheel is connected with the conveying auger 3, and the conveying auger is connected with the soil shaker and the short-distance fast conveying mechanism 4 and the feeding port 5. Front-mounted straw automatic picking and pretreatment system.

[0028] The front-mounted straw automatic picking and pretreatment system mainly completes the automatic picking, soil removal and primary crushing of straw scattered on the ground, in order to provide the necessary foundation for the transportation and further processing of raw materials on...

Embodiment 2

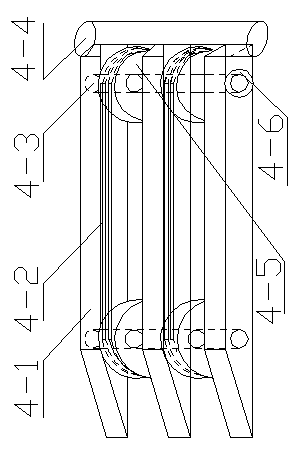

[0035] The difference between this embodiment and Embodiment 1 is that, as attached figure 1 , attached figure 2 As shown, the fully automatic collection, crushing and compacting combined machine for waste crop straw in the field also includes a crushing-drying-densification integrated system, and the crushing-densification integrated system includes a conveyor belt 6, which connects the Earth shaking and short-distance rapid conveying mechanism, the nail gear is connected to the first pulley group 14, the first pulley group is connected to the second pulley group 15, and the second pulley group is connected to the cutting saw blade wheel , the second pulley set is connected to the third pulley set 16 and the first sprocket set 17, the third first sprocket set is connected to the reducer 20, and the reducer is connected to the The third pulley set is connected to the transmission shaft 4-3.

Embodiment 3

[0037] The difference between this embodiment and Embodiment 2 is that, as attached figure 1 , attached figure 2 As shown, in the fully automatic collection, crushing and compacting combined machine for discarded crop straw in the field, the reducer 20 is connected to the pulverizer 21 through the fourth pulley set 22, and the pulverizer is connected to the cyclone separator 8, and the cyclone separates The mold is connected to the molding machine 28, the mold of the molding machine is connected to the generator 32, and the generator is connected to the diesel engine 7 through the fifth pulley set 30. The diesel engine has a diesel engine output shaft 18, and the diesel engine output shaft passes through the first A set of five pulleys connects the generator.

[0038] The waste heat of the exhaust gas from the diesel engine is used to dry the initially pulverized straw, and the smoked material has good flexibility and is conducive to forming. The chimney of the diesel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com