Preparation method of five-axis numerical control mechanical arm and five-axis numerical control mechanical arm

A robotic arm and arm technology, applied in the preparation of five-axis CNC robotic arms, in the field of five-axis CNC robotic arms, can solve the problem of small selection range, inability to meet the development of machinery manufacturing industry, inability to achieve multi-degree-of-freedom, three-dimensional space retrieval, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

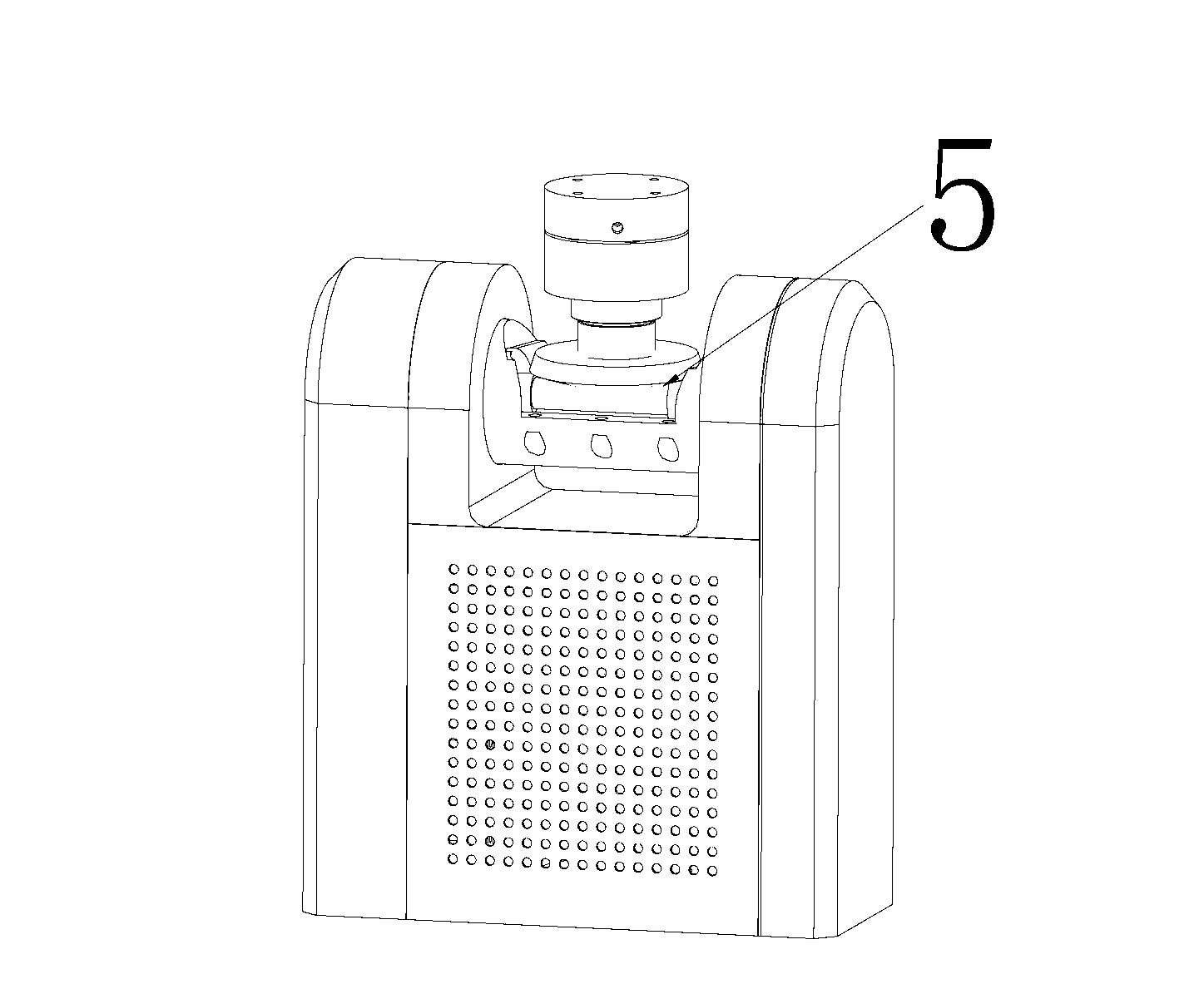

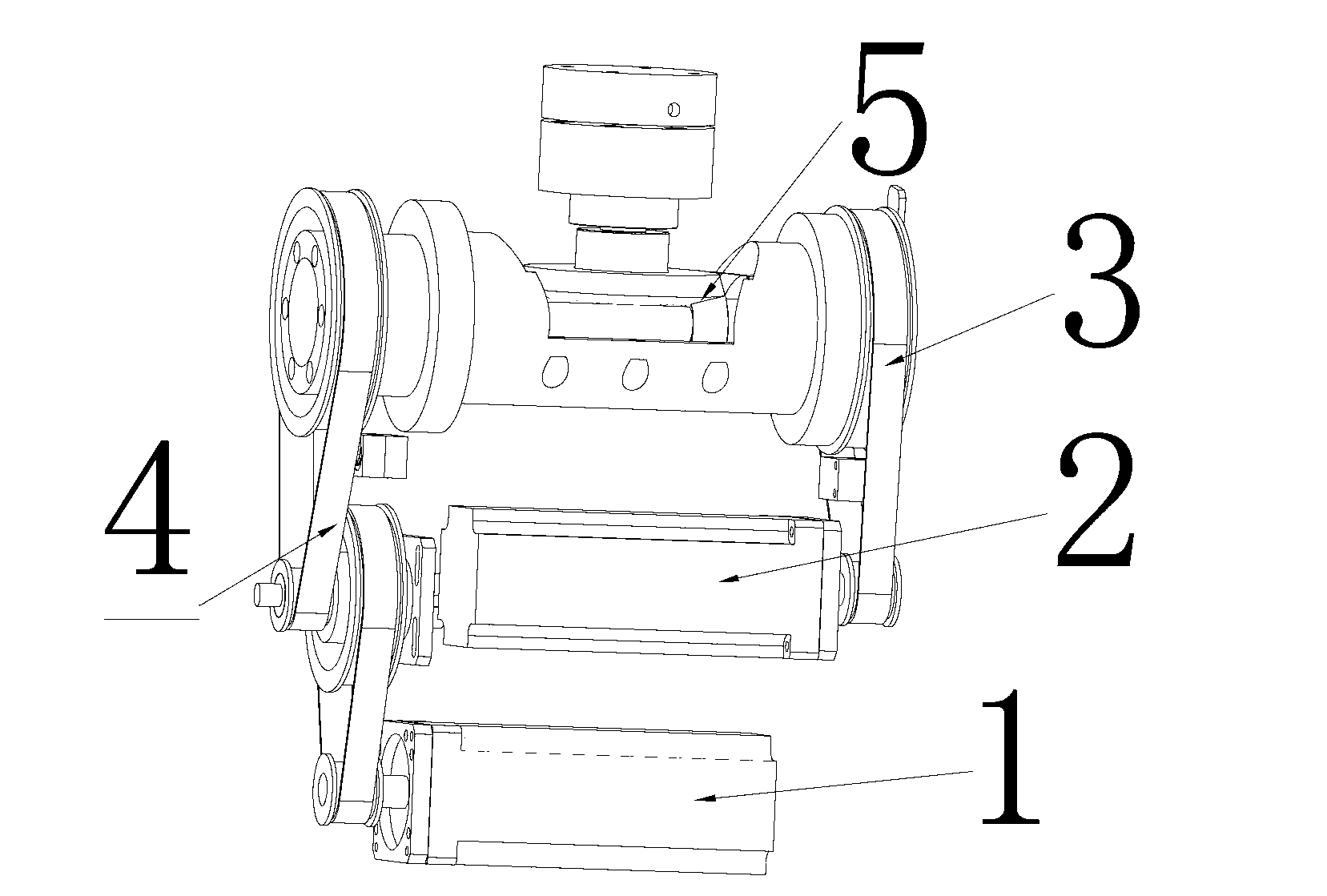

[0033] Example: see Figure 1 to Figure 3 , a method for preparing a five-axis numerically controlled mechanical arm provided in this embodiment, comprising the following steps:

[0034] (1) A mechanical arm body is provided, and an X-axis arm, a Y-axis arm, and a Z-axis arm are arranged on the mechanical arm body, and the translation work is driven by a servo motor on the X-axis, Y-axis, and Z-axis respectively;

[0035] (2) The control device and the operation feedback device of the robotic arm are respectively set on the main body of the robotic arm, and are connected to each other through the CAN control bus;

[0036](3) At the end of the Z-axis arm, a B-axis and C-axis motion mechanism are arranged, and the B-axis and C-axis motion mechanism are driven by a servo motor to rotate 180° on the B-axis and 360° on the C-axis;

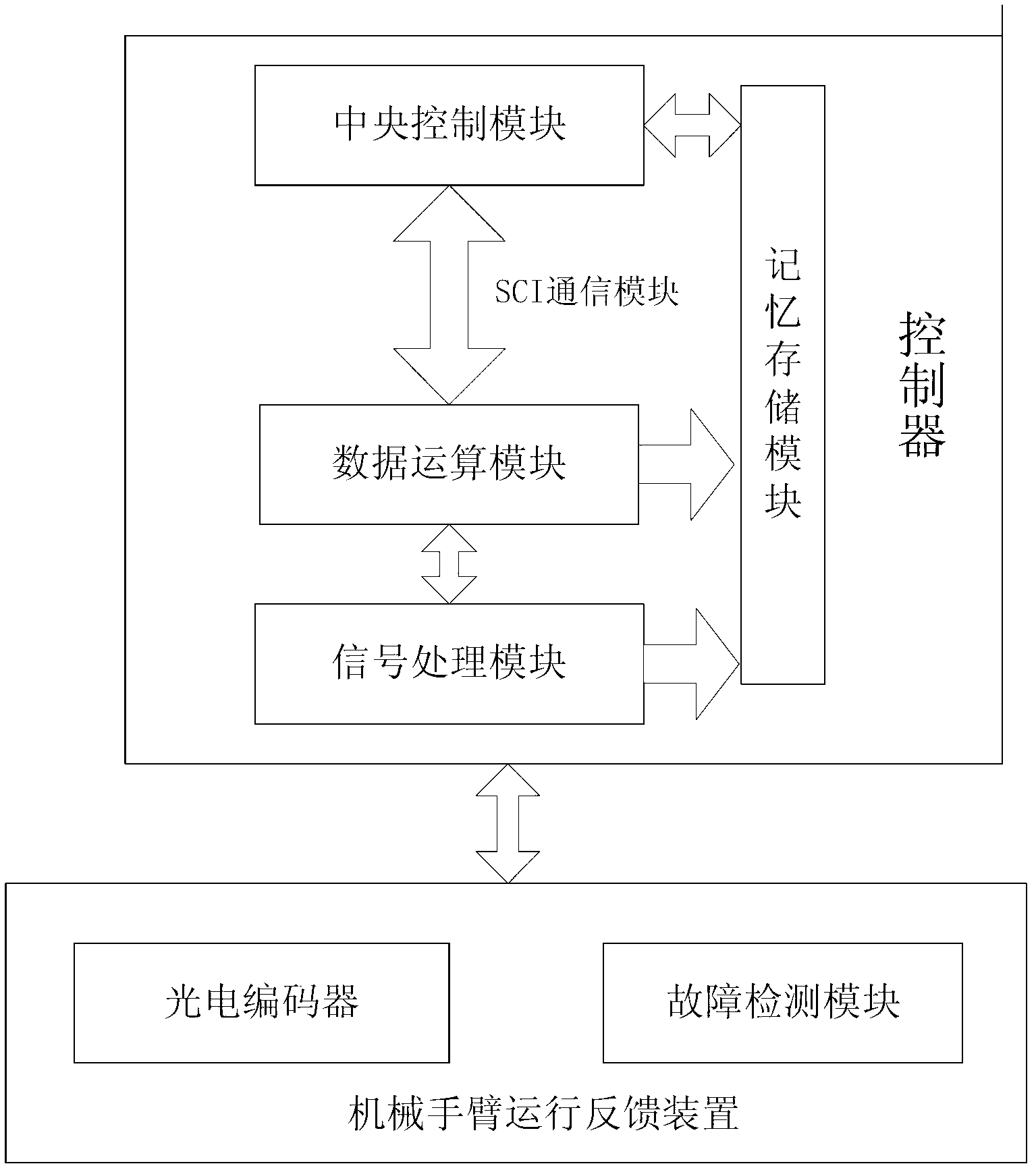

[0037] (4) central control module, data operation module, memory storage module and signal processing module connected sequentially are set in describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com