Foundation treatment pile and pile splicing method thereof

A foundation treatment and pile body technology, applied in sheet pile wall, infrastructure engineering, construction, etc., can solve the problems of difficult to guarantee welding quality, occupational hazards of operators, long welding cooling time, etc., to achieve reliable construction quality and reduce physical Hazards, good product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

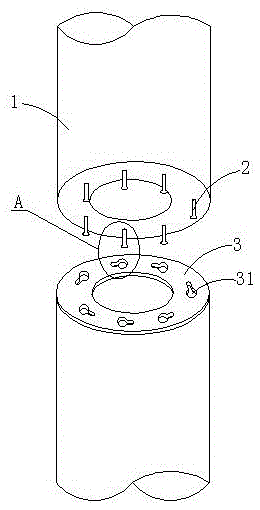

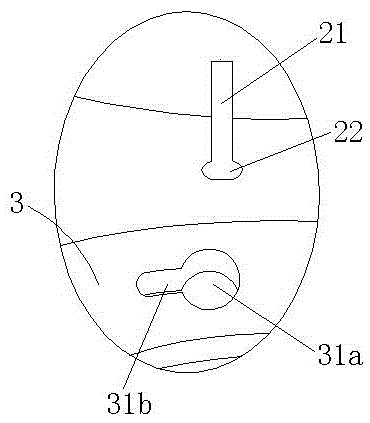

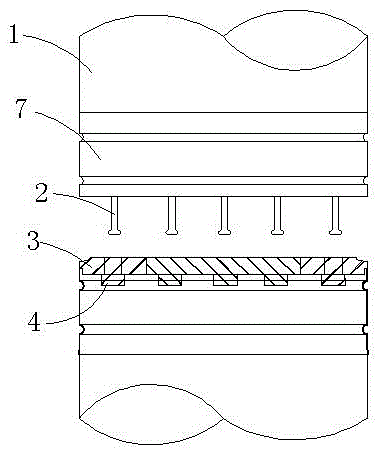

[0028] Such as Figure 1 to Figure 4 The example shown,

[0029] Explanation of icon numbers: prefabricated single pile 1, connecting head 2, rod body 21, expanding head 22, end plate 3, connecting hole 31, piercing reinforcement hole 31a, sliding reinforcement hole 31b, metal box 4, spiral stirrup 5, prestressed steel bar 6. Pile hoop 7.

[0030] Such as Figure 1 to Figure 4 as shown,

[0031] A foundation treatment pile, comprising a pile body formed by sequentially connecting prefabricated single piles 1, one end of the prefabricated single pile 1 is uniformly provided with a connecting head 2, and the connecting head 2 includes a rod body 21 arranged in the axial direction and an enlarged head at the outer end of the rod body 21 22. The diameter of the expanding head 22 is larger than the diameter of the rod body 21; the other end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com