Tensioning and connection integrated prefabricated pile

A prefabricated pile and one-piece technology, applied in sheet pile walls, buildings, foundation structure engineering, etc., can solve the problems of difficult pile sinking, long retention time, and inability to construct, so as to achieve reliable construction quality, reduce air pollution, and improve construction efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

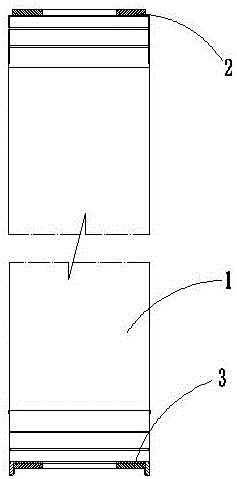

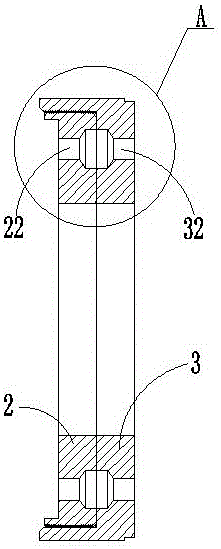

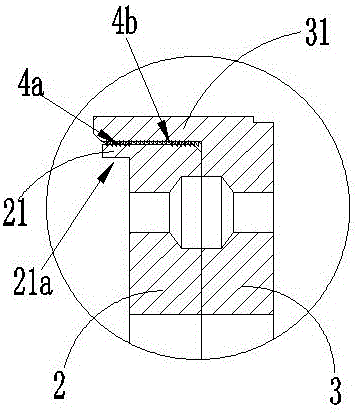

[0037] Example one, as Figure 1 to Figure 4 shown,

[0038] An integral prefabricated pile with tension and connection, comprising a prefabricated pile body 1, one end of the prefabricated pile body 1 is provided with a first connecting flange 2, the end section is in a "convex" shape, and the other end of the prefabricated pile body 1 is provided with a first connection flange 2. The second connecting flange 3 has a "concave" shape in cross section. The second connecting flange 3 is axially extended to form an annular retaining ring 31. The first connecting flange 2 and the second connecting flange 3. Matching; when connecting the piles, the upper and lower piles are connected to the piles through the mechanical connection between the first connecting flange 2 and the second connecting flange 3 that are matched.

[0039] When connecting, the prefabricated piles are connected in sequence, that is, the first connecting flange 2 of the lower pile is connected with the second c...

Embodiment 2

[0048] Embodiment two, as Figure 5 to Figure 8 shown,

[0049] The prefabricated pile in this embodiment is similar in structure to the prefabricated pile in Embodiment 1. The difference is that in this embodiment, the first connecting flange 2 and the second connecting flange 3 are connected by radial positioning. , the outer circumference of the first connecting flange 2 is radially provided with a first fixing hole 5a, and the annular retaining ring 31 is radially provided with a second fixing hole 5b at the corresponding position of the first fixing hole 5a. The hole 5b penetrates the annular retaining ring 31, and the corresponding first fixing hole 5a and the second fixing hole 5b are provided with a fixing member 6 in both.

[0050] The fixing member 6 is radially placed in the aligned first fixing hole 5a and the second fixing hole 5b from the outside to the inside. After fixing, a part of the fixing member 6 is located in the first fixing hole 5a and the other part ...

Embodiment 3

[0054] Example three, as Figures 9 to 14 shown,

[0055] The prefabricated pile in this embodiment is similar in structure to the prefabricated pile in Embodiment 1, the difference is that in this embodiment, the first connecting flange 2 and the second connecting flange 3 are connected by a snap ring 8 , the outer periphery of the first connecting flange 2 is radially provided with a first snap ring groove 7a, and the annular retaining ring 31 is radially provided with a second snap ring groove 7b at the corresponding position of the first snap ring groove 7a, The snap ring 8 is placed in the snap ring cavity formed by the first snap ring groove 7a and the second snap ring groove 7b.

[0056] In the embodiment, the snap ring 8 is an annular structure, and the annular structure is provided with a notch 8a. Due to the provision of the gap 8a, the snap ring 8 of the annular structure has elasticity; when connecting, the gap 8a is first enlarged so that the snap ring 8 can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com