Bacterial strain for preparing 3-hydroxy butanone and uses thereof

The technology of hydroxybutanone and strain is applied in the field of 3-hydroxybutanone-producing strains, which can solve problems such as difficulty in producing 3-hydroxybutanone by fermentation, and achieve the effect of alleviating the shortage of petrochemical resources and being environmentally friendly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Collect soil samples from the surface of the orchard in Shuaiqi Farm, Pukou District, Nanjing, weigh 3.0 grams, bake at 90°C for 36 hours, add to 100 mL of sterile water to make a suspension; take 0.5 mL of the bacterial suspension and transfer it to a 150 mL Erlenmeyer flask, The volume of the enrichment medium in the Erlenmeyer flask was 50mL. After the enrichment culture was carried out at 35°C for 24h, the culture medium was taken and diluted to 10 -6 , take 0.1mL of the diluted solution and spread it on a plate containing enriched medium, and after culturing at 35°C for 24 hours, pick a single colony and conduct V-P (Vagex-Proskauer) experiments one by one. The specific method is: inoculate the strain to be tested on In a 10mL culture tube filled with 5mL of V-P experimental medium, culture at 35°C for 4 days, take 2.5mL of culture medium, first add 0.6mL of pure alcohol solution containing 5% α-naphthol, then add 40% potassium hydroxide Aqueous solution 0.2mL, sha...

Embodiment 2

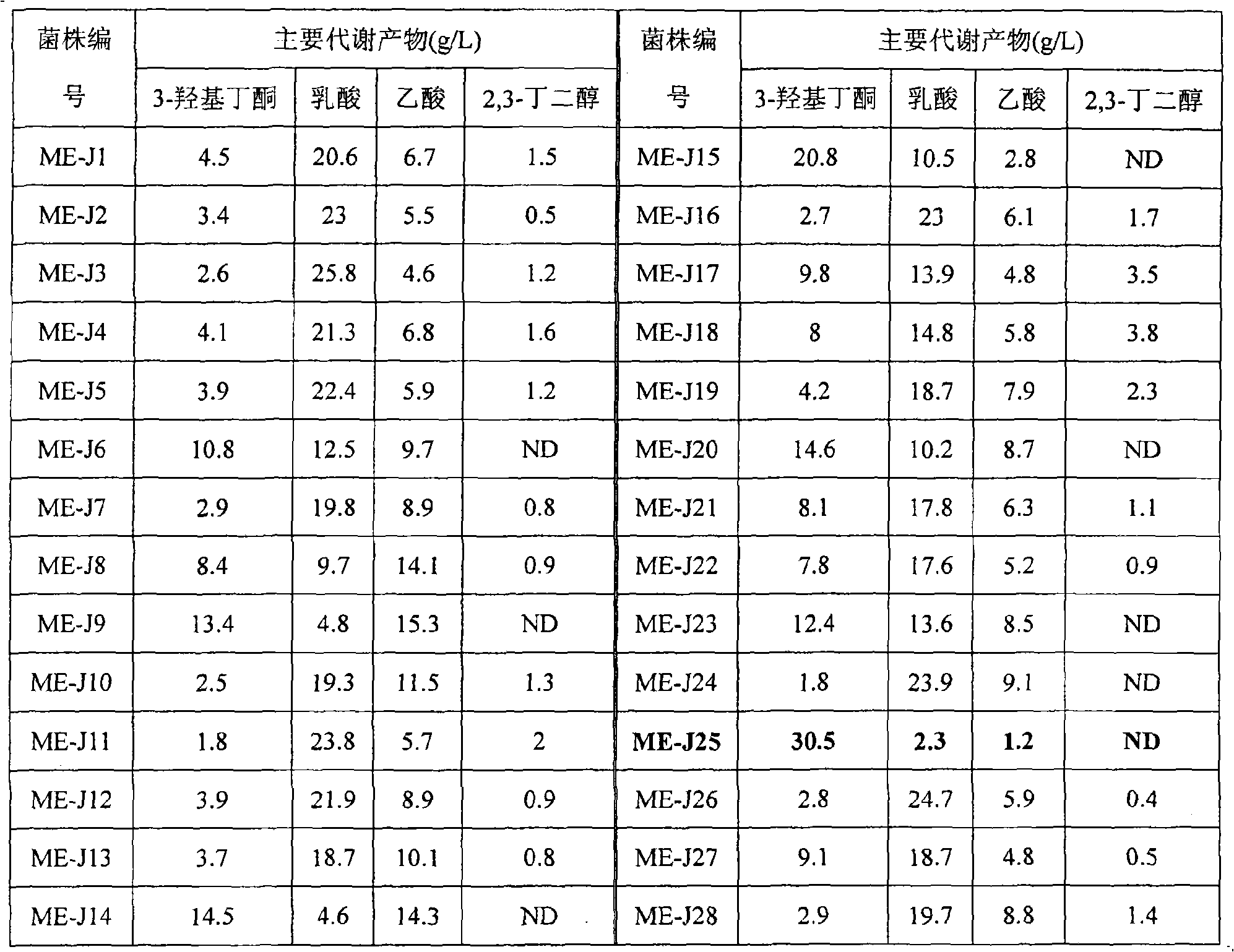

[0046] The 77 strains of V-P positive strains obtained in Example 1 were transferred one by one to a screening plate equipped with a separation medium with a sterilized toothpick, cultivated in an incubator at a temperature of 37°C, and after cultivating for 24 hours, it was found that there were The 28 corresponding strains can grow normally, and these 28 single colonies were collected respectively, numbered as: ME-J1~ME-J28, and cultured in 10mL culture tubes containing 5mL fermentation medium for 24h; after the culture, 12000r / Centrifuge for 5 minutes, and measure the content of 3-hydroxybutanone in the supernatant by HPLC. It is found that most of the strains produce more lactic acid and acetic acid, and a few strains produce more 3-hydroxybutanone. Among them, the strain ME-J25 produces 3-hydroxybutanone. Butanone is most notable.

[0047] Metabolite distribution of table 1V-P positive strains

[0048]

[0049] Note: ND means "not detected".

[0050] in:

[0051] S...

Embodiment 3

[0054] To the ME-J25 bacterial strain obtained by screening in Example 2, press "Common Bacterial System Identification Manual" (Dong Xiuzhu, Cai Miaoying, etc. Common Bacterial System Identification Manual (First Edition). Beijing: Science Press, 2001, p 59) Physiological and biochemical characteristics were identified (Table 2). According to the comparison of morphology and physiological and biochemical characteristics in Table 2, the strain ME-J25 was identified as Paenibacillus polymyxa, which has been preserved in the China Microbiological Culture Collection Management Committee General Microbiology Center, the preservation number is CGMCC No.2505

[0055] Table 2 Comparison table of identification results of physiological and biochemical characteristics of strain ME-J25

[0056]

[0057] Note: +: >90% strains are positive; -: >90% strains are negative; ++: produce acid and gas

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com