Core-shell structure phase change material and preparation method thereof

A phase change material, core-shell structure technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of limited application function, easy leakage, packaging difficulties, etc., to protect the ecological environment, prevent leakage, improve The effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

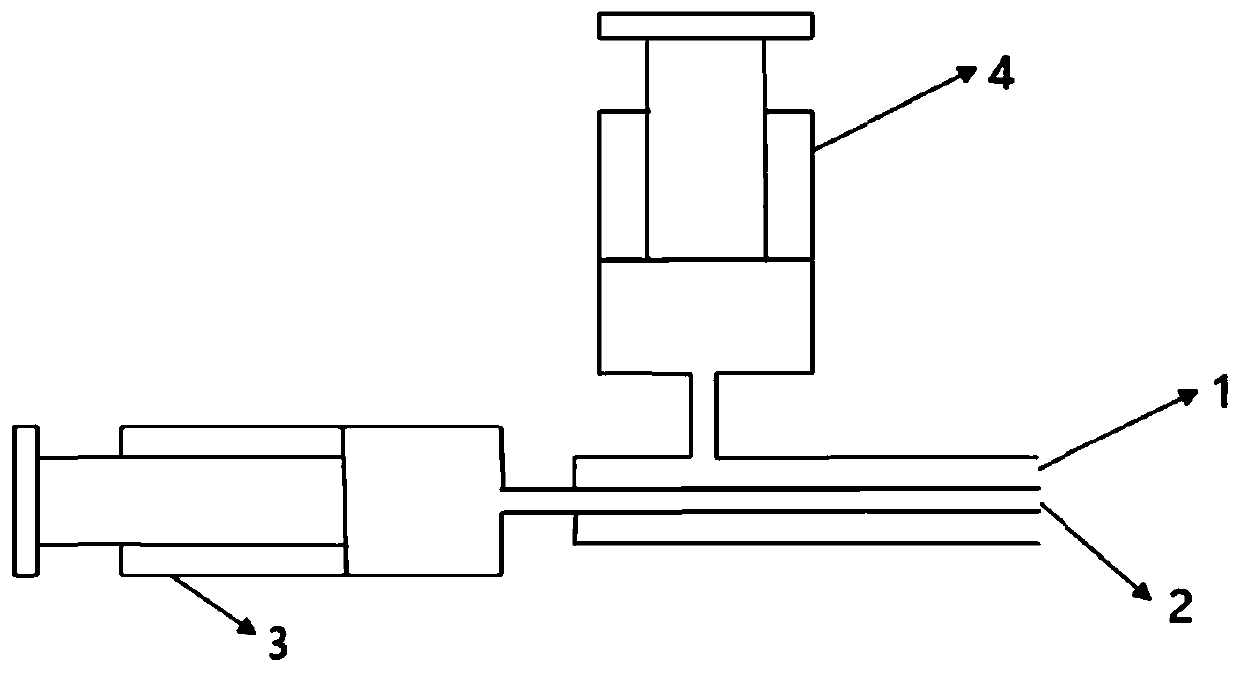

[0027] A kind of core-shell structure phase change material, its preparation method comprises the following steps:

[0028] S1. Weigh 50g of high-density polyethylene HDPE, 50g of solid paraffin, 2.5g of carbon nanotubes and 2.5g of antioxidant 1010; wherein, paraffin is a phase change material with a phase change temperature of 52.6°C and a latent heat of phase change of 210J / g. Paraffin is used as the core material; HDPE is used as the basic support material, carbon nanotubes are used as thermal conductivity enhancers, and HDPE, carbon nanotubes and antioxidant 1010 are used as shell materials;

[0029] S2. Put high-density polyethylene (HDPE) and antioxidant 1010 in a silicone oil bath, and heat at a constant temperature of 160°C for about 30 minutes until it completely melts; add carbon nanotubes, maintain the temperature at 160°C, and stir magnetically The rotating speed of the device is set at 30r / min, and heating is performed for about 30min while stirring, so that the ...

Embodiment 2

[0036] A core-shell structure phase change material, the difference between its preparation method and the preparation method of the core-shell structure phase change material in Example 1 is that the coaxial spinning device used in this example adopts 19G / 15G combined coaxial spinning Silk needle, that is, the inner needle of the coaxial spinning device (i.e. the core layer liquid channel) is a 19G needle with an inner diameter of 0.70mm and an outer diameter of 1.07mm; the outer needle (i.e. the shell liquid channel) is a 15G needle with an inner diameter of It is 1.37mm, and the outer diameter is 1.8mm; Other operations are the same as the preparation method in Example 1. It is measured that the thermal conductivity of the core-shell structure phase change material prepared in this embodiment is 3.343W / (m·K), and the latent heat of phase change is 80.5J / g.

Embodiment 3

[0038] A core-shell structure phase change material, the difference between its preparation method and the preparation method of the core-shell structure phase change material in Example 1 is that the coaxial spinning device used in this example adopts 22G / 17G combined coaxial spinning Silk needle, that is, the inner needle of the coaxial spinning device (i.e. the core layer liquid channel) is a 22G needle with an inner diameter of 0.41mm and an outer diameter of 0.72mm; the outer needle (i.e. the shell liquid channel) is a 17G needle with an inner diameter of 1.01mm, outer diameter 1.49mm; Other operations are the same as the preparation method in Example 1. It is measured that the thermal conductivity of the core-shell structure phase change material prepared in this embodiment is 3.859W / (m·K), and the latent heat of phase change is 61.6J / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com