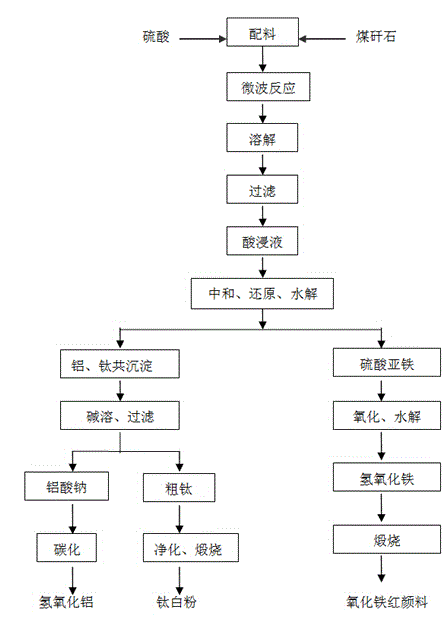

Method for preparing titanium dioxide from high-titanium coal gangue

A technology of coal gangue and titanium dioxide, which is applied in the removal of titanium dioxide, solid waste, titanium oxide/hydroxide, etc., can solve the problems of secondary pollution and low efficiency, and achieve high utilization rate, convenient operation and acid utilization rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Add 98% concentrated sulfuric acid to coal gangue (titanium dioxide content 4.0%, ground through 80-mesh standard sieve), heat with microwaves, react for 1 hour, add water with a mass 4 times the mass of coal gangue after the reaction is completed, Place it in a water bath at 30°C to fully dissolve, and filter to obtain an acid leaching solution, in which concentrated sulfuric acid and coal gangue are in a mass ratio of 1.4:1, and TiO in the acid leaching solution 2 、 Al 2 o 3 , T Fe The contents are 4.79g / L, 28.92g / L, 19.58g / L respectively;

[0030](2) Add sodium carbonate to the acid leaching solution to neutralize and adjust the pH of the acid leaching solution to 1 to prepare an acid leaching neutralization solution;

[0031] (3) Add excess iron wire to the acid leaching neutralization solution to reduce the ferric iron in it, filter after the reduction reaction is completed, dilute the neutralization solution according to the volume ratio of the filtrate and...

Embodiment 2

[0035] (1) Add 98% concentrated sulfuric acid to coal gangue (titanium dioxide content 5.0%, ground through a 80-mesh standard sieve), heat with microwaves, and react for 1.2 hours. After the reaction is completed, add water 4.5 times the mass of gangue , placed in a water bath at 50°C to fully dissolve, and filtered to obtain an acid leaching solution, in which concentrated sulfuric acid and coal gangue are in a mass ratio of 1.6:1; TiO in the acid leaching solution 2 、 Al 2 o 3 , T Fe The contents are 5.15g / L, 29.37g / L, 19.82g / L respectively;

[0036] (2) Add sodium carbonate to the acid leaching solution to neutralize and adjust the pH of the acid leaching solution to 1.5 to prepare an acid leaching neutralization solution;

[0037] (3) Add excess iron wire to the acid leaching neutralization solution to reduce the ferric iron in it, filter after the reduction reaction is completed, dilute the neutralization solution according to the volume ratio of the filtrate and wate...

Embodiment 3

[0041] (1) Add 98% concentrated sulfuric acid to coal gangue (3.45% titanium dioxide content, ground through a 80-mesh standard sieve), heat it with microwaves, and react for 1.6 hours. After the reaction is completed, add water five times the mass of coal gangue , placed in a water bath at 30°C to fully dissolve, and filtered to obtain an acid leaching solution, in which concentrated sulfuric acid and coal gangue are in a mass ratio of 1.6:1; TiO in the acid leaching solution 2 、 Al 2 o 3 , T Fe The contents are 3.75g / L, 22.36g / L, 16.20g / L respectively;

[0042] (2) Add potassium carbonate to the acid leaching solution to neutralize and adjust the pH of the acid leaching solution to 1.0 to prepare an acid leaching neutralization solution;

[0043] (3) Add excess aluminum powder to the acid leaching neutralization solution to reduce the ferric iron in it, filter after the reduction reaction is completed, dilute the neutralization solution according to the volume ratio of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com