Method for extracting coal seam gas through ground fracturing and underground horizontal drill holes

A technology for horizontal drilling and coalbed methane, which is applied in gas discharge, earthwork drilling, wellbore/well components, etc., can solve the problems of difficult drilling construction for gas drainage, low coal seam permeability, and soft coal quality, etc. Achieve the effect of increasing clean energy supply, improving coal seam permeability and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

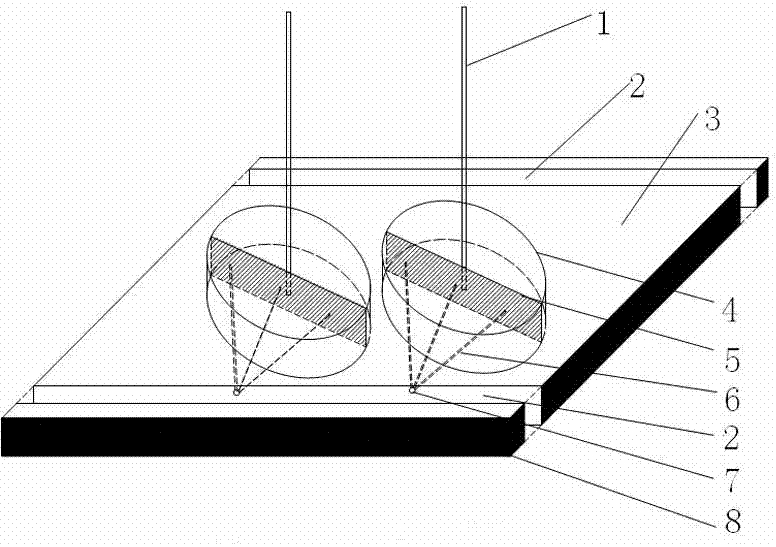

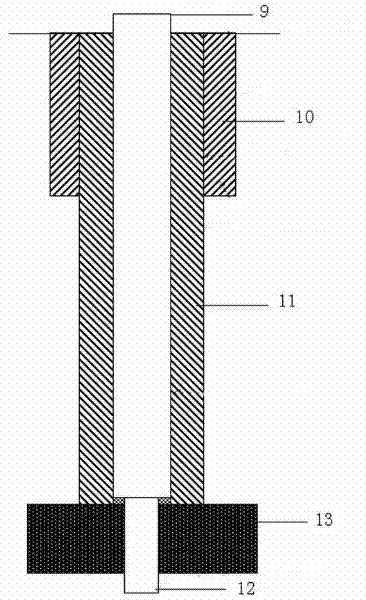

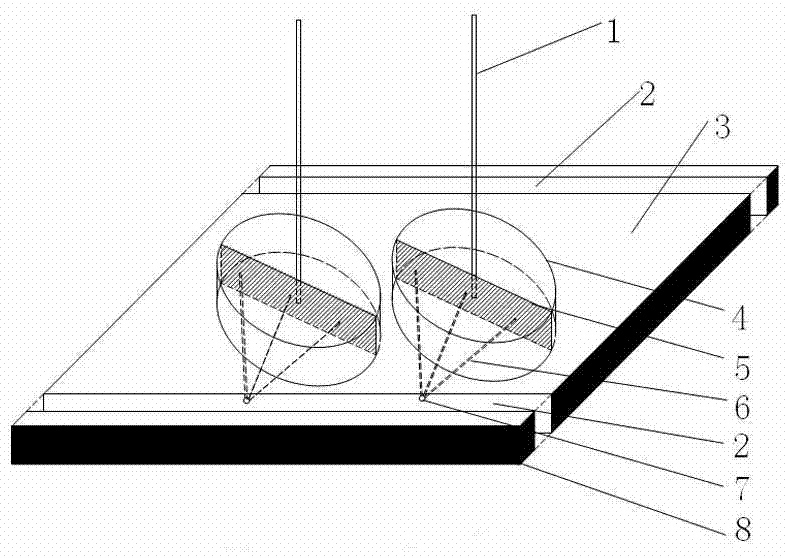

[0028] A method for extracting coalbed methane from a ground fracturing underground horizontal borehole described in the present invention (such as figure 1 shown), including the following steps:

[0029] 1) Well layout design

[0030] The well layout is carried out on the coal mining face 3 in strict accordance with the tunneling speed of the underground roadway and the construction situation of the gas drainage drilling. In order to prevent ground fracturing from affecting the underground roadway and gas drainage boreholes (pressure jump), the drilling and fracturing construction should be completed at least 350m away from the tunneling surface of roadway 2, or at least 150m away from the underground gas drainage borehole. After completion, close the well and wait for the underground gas drainage drilling. The well spacing is 200-300m, and the coalbed met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com