Novel high-grade miscellaneous copper refining furnace system

A refining furnace, high-grade technology, applied in the field of new high-grade miscellaneous copper refining furnace system, can solve the problems of high unit energy consumption, high cost, no energy saving, low cost, etc., and achieve the effect of reducing investment cost and ingenious and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

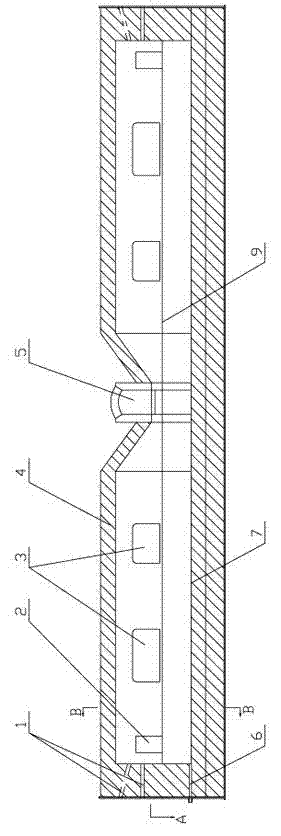

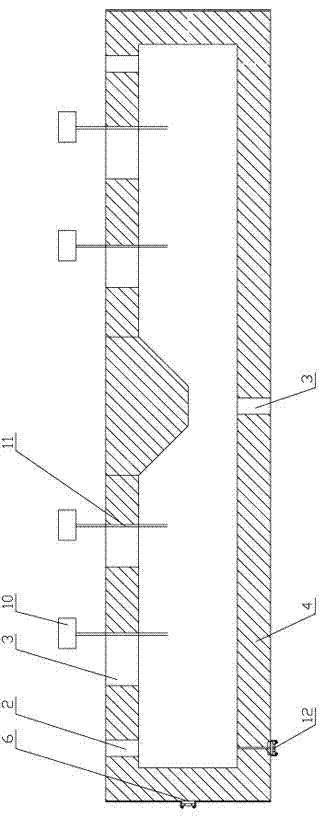

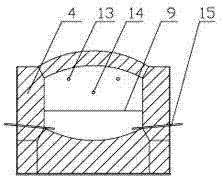

[0030] see Figure 1-Figure 10 , the present invention is a new type of high-grade miscellaneous copper refining furnace system, including a furnace 4 and an auxiliary system, characterized in that: the furnace body is formed by docking and combining the furnace tails of two fixed refining reverberatory furnaces A large-capacity miscellaneous copper refining furnace, the two furnaces are connected to form a furnace, two groups of combustion ports are symmetrically arranged in the middle of the furnace wall at the left and right ends of the furnace body, and each group of combustion ports is equipped with a combustion system and supply Oxygen gas supply system, each group of combustion ports is equipped with three small combustion ports 1 distributed in an inverted isosceles triangle, the small combustion port in the middle is installed horizontally 0.6m above the copper liquid level, and the two small combustion ports on both sides are higher than the copper liquid The surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com