Salt-containing organic effluent treatment method

A technology of organic waste liquid and treatment method, which is applied in the direction of filtration treatment, water/sewage treatment, pyrolysis treatment of sludge, etc., and can solve the problems of unstable treatment effect, rust, expensive equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

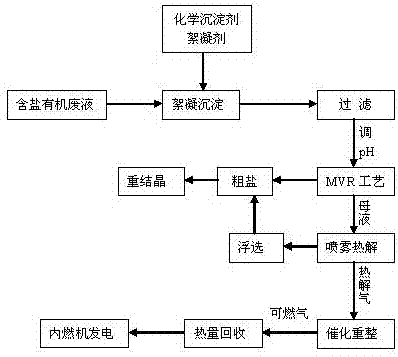

[0012] Such as figure 1 As shown, the comprehensive treatment process of a salt-containing organic waste liquid in the present invention includes the following steps: concentrating the salt-containing organic waste liquid, and removing large particles in the waste water through chemical precipitation, flocculant flocculation, filtration and other means. After pretreatment, the waste liquid enters the MVR system after adjusting the pH value and adding chemical reagents such as defoamers and decolorizers to meet the process requirements, which can effectively remove most of the salt and concentrate the mother liquor to enrich organic matter. The salt content of the concentrated mother liquor is 10%~50%, and the COD is 50,000~900,000. The concentrated mother liquor enters the spray pyrolysis section, and the pyrolysis temperature is 300~600°C. The appropriate process conditions are determined according to the nature of the waste liquid. The pyrolyzed solids come out from the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com