Single-stage low-switch-stress and low-output-ripple LED drive circuit

A technology of LED driving and switching stress, applied in the field of LED lighting driving power supply design, can solve the problems of unsolved switching stress, large output low frequency ripple, large switching stress, etc., to achieve energy utilization, reduce output low frequency ripple, The effect of reducing voltage stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

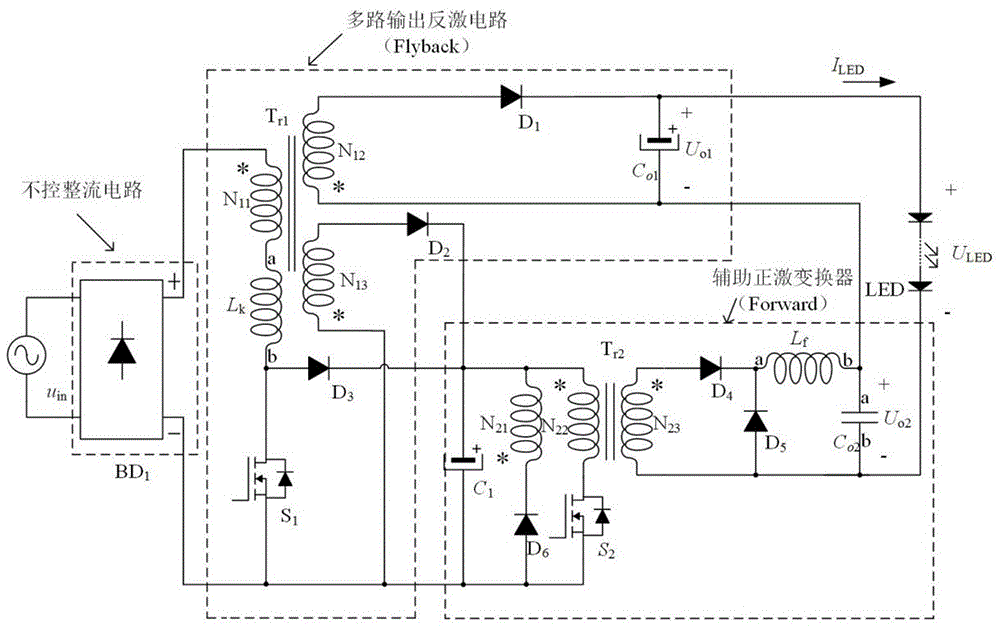

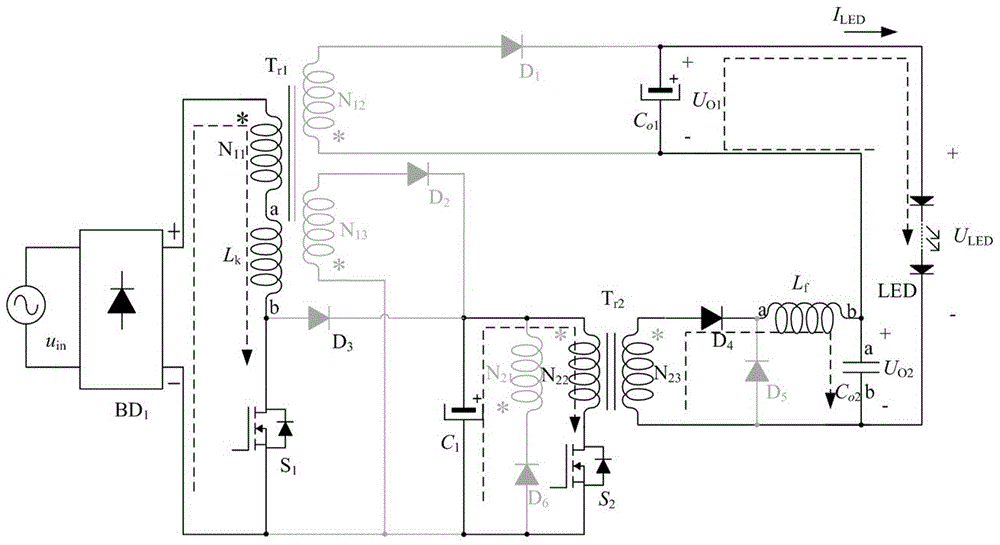

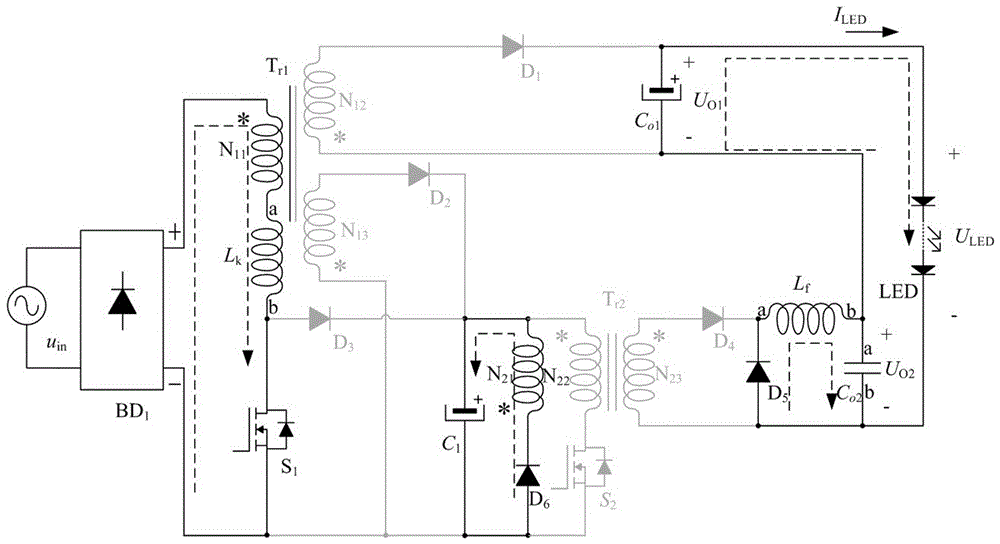

[0028] 1. If figure 1 As shown, this embodiment provides a single-stage LED driver circuit with low switching stress and low output ripple, including input AC power u in , diode rectifier bridge BD 1 , main transformer T r1 , auxiliary transformer T r2 , the first power MOS switch tube S 1 , the second power MOS switch tube S 2 , the first power diode D 1 , the second power diode D 2 , the third power diode D 3 , the fourth power diode D 4 , the fifth power diode D 5 , the sixth power diode D 6 , electrolytic capacitor C 1 , the first output capacitor C o1 , the second output capacitor C o2 , Output filter inductance L f , LED light load; the main transformer T r1 By primary excitation winding N 11 , secondary winding output N 12 and N 13 and leakage inductance L k constituted, the auxiliary transformer T r2 By the demagnetization wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com