Method for producing methane by microbial electrocatalysis enhanced organic waste

A technology for microbial electricity and methane production, which is applied in waste fuel, fermentation, etc., can solve the problems of inability to rapidly convert methane into organic wastewater, shock, poor stability and robustness, and achieve advanced treatment and energy utilization, and reduce carbon emissions. Emissions, the effect of improving the efficiency of methanation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

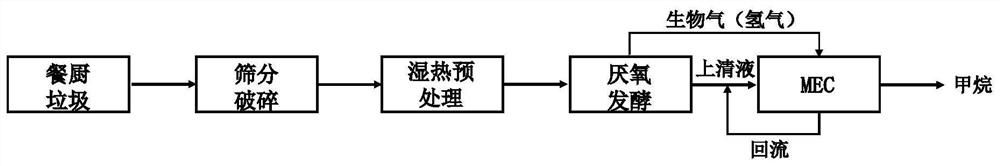

[0033] like figure 1As shown, the food waste crushing and screening unit removes large materials such as bones and fish bones, enters the wet heat pretreatment unit, and enters the anaerobic fermentation phase reactor through wet heat hydrolysis. 3 d), operating at pH 5.5-6.5, at 45-55°C for acid-producing and hydrogen-producing fermentation, the hydrogen content in the biogas produced is more than 50%, and the hydrogen production rate is 100-150L / (kgVS·d), The content of ethanol and volatile fatty acid in the fermentation broth is 1000-1500mg / L (butyric acid is the main organic acid component).

[0034] The methane-producing MEC reactor needs to be started and debugged in advance. The anaerobic granular sludge required for start-up is taken from the anaerobic digestion tank of citric acid wastewater, and the anaerobic granular sludge is mixed with glucose and ethanol solution for methanation activation treatment. Among them, a small amount of ethanol promoted the proliferat...

Embodiment 2

[0037] Food waste enters the anaerobic fermentation reactor after being crushed, screened, and pretreated by heat and humidity. At an organic load of 9kgVS / (m 3 d), the operating pH is 6, acid-producing hydrogen-producing fermentation is carried out under high temperature conditions of 35±1°C, the hydrogen production rate is 60-100L / (kgVS·d), and the content of ethanol and volatile organic acids in the fermentation broth is 13000- 16000mg / L, including acetic acid 6000-8000mg / L, propionic acid 1000-1200mg / L, butyric acid 5600-6000mg / L.

[0038] The start-up of the MEC reactor in the methanogenic phase is the same as in Example 1.

[0039] The fermentation liquid produced by the anaerobic fermentation of food waste is centrifuged and input into the successfully started-up methanogenic phase MEC reactor, and the biogas containing hydrogen is transported to the reactor through the gas pump, and is evenly distributed in the production area by the bottom gas diffuser. Inside the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com