Method for preparing Ni-based catalyst by ultrasonic-assisted impregnation method

An ultrasonic and catalyst technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of increased preparation cost, inability to guarantee the amount of impregnation, and many steps, so as to reduce catalyst costs and improve The effect of CO2 methanation efficiency and improvement of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

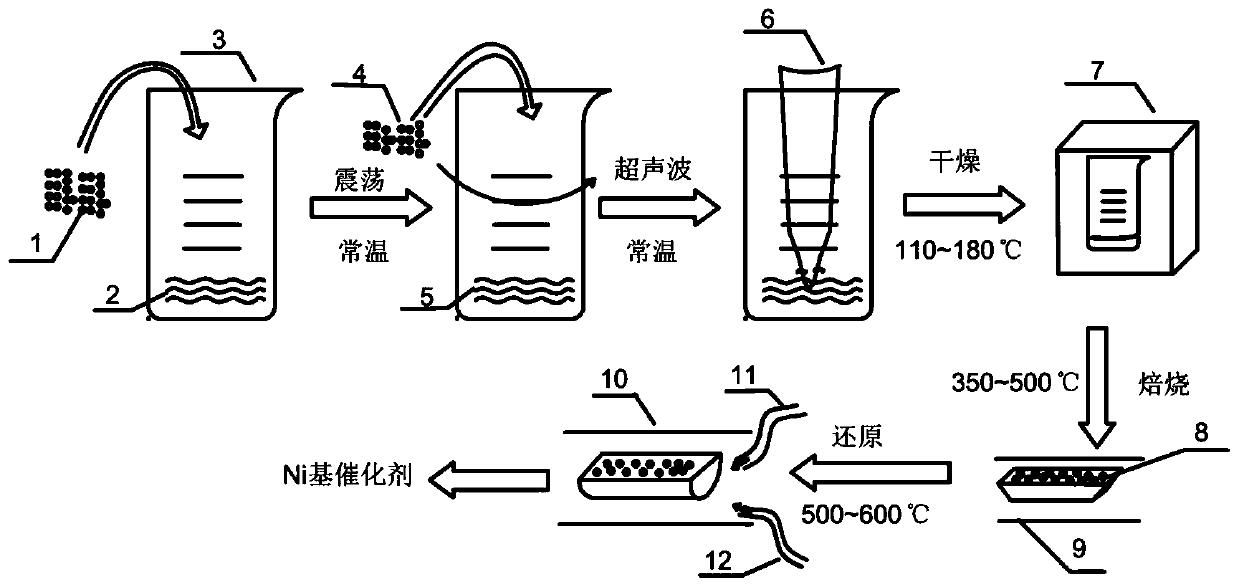

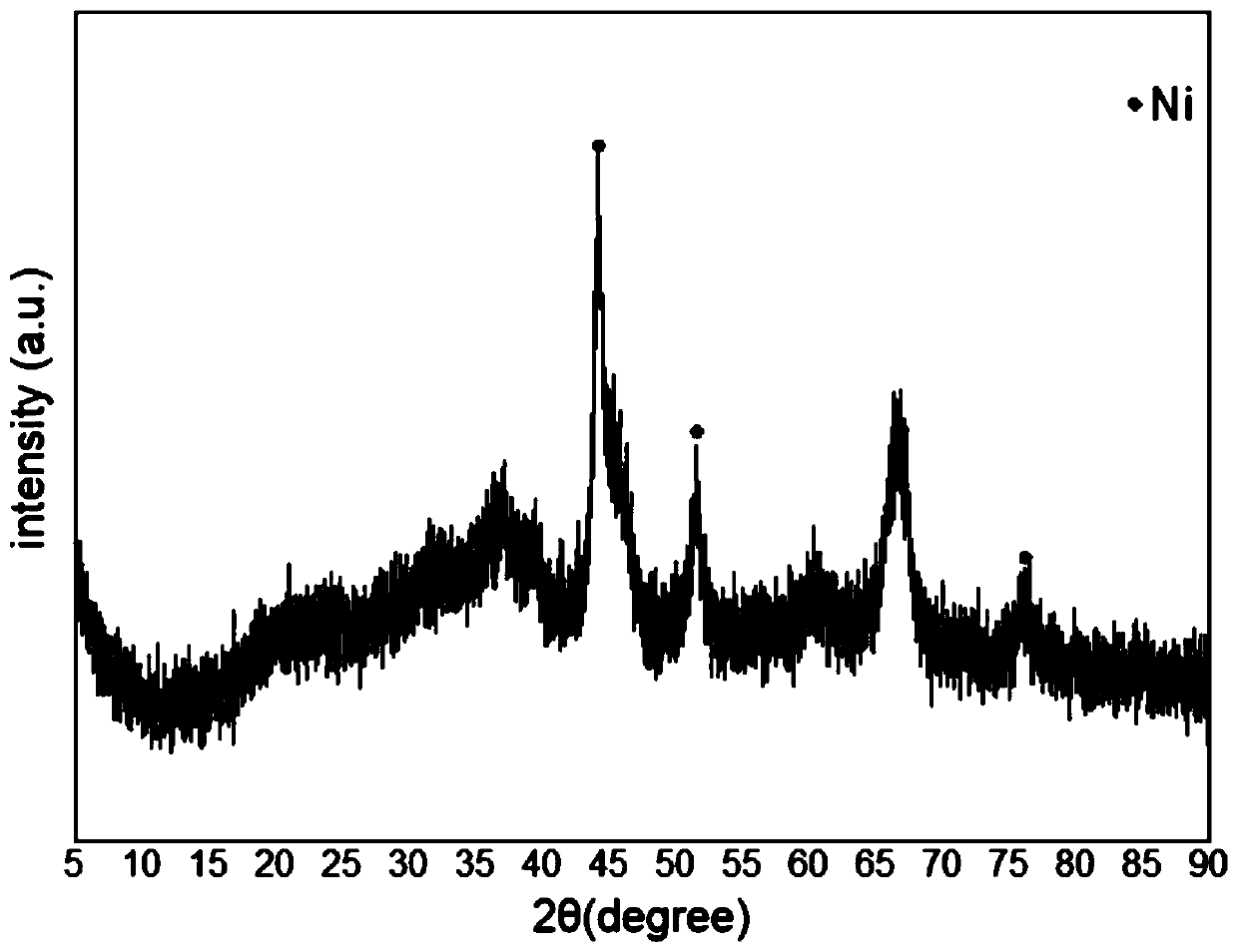

[0022] Such as figure 1 As shown, 2.918g Ni(NO 3 ) 2 ·6H 2 O 1 was fully dissolved in 8.0ml deionized water 2 to obtain impregnation solution 5; then 4.000g γ-Al 2 o 3 Carrier 4 was added to the above impregnation solution 5, fully shaken for 10 minutes, then placed in ultrasonic disperser 6 for 100W ultrasonic dispersion for 15 minutes, then left at room temperature for 36 hours, dried in 110°C drying oven 7 for 12 hours, and placed in a muffle furnace 9 was roasted at 450°C at a rate of 5°C / min for 3 hours, and the obtained sample 8 was passed into H2 in a high-temperature tube furnace 10 at 550°C 2 Mixed gas of 11 and Ar 12, H 2 The volume ratio of Ar and Ar is 1:9, and the reduction is 3h to obtain 5g of Ni / γ-Al with a loading capacity of 15%. 2 o 3 catalyst.

Embodiment 2

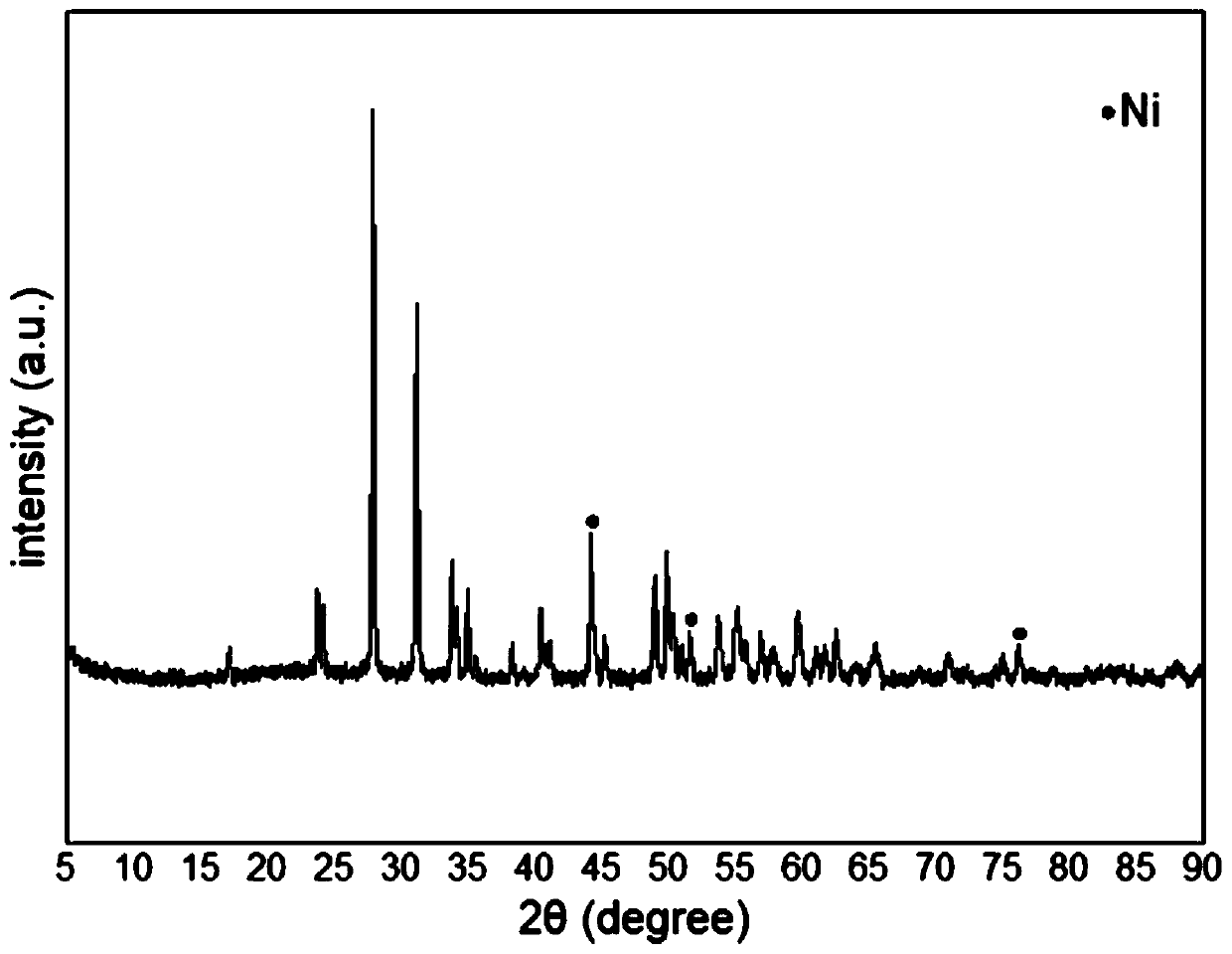

[0024] Such as figure 1 As shown, 2.918g Ni(NO 3 ) 2 ·6H 2 O 1 was fully dissolved in 1.2ml deionized water 2 to obtain impregnation solution 5; then 0.300g ZrO 2 Carrier 4 was added to the above impregnation solution 5, fully shaken for 15 minutes, then placed in ultrasonic disperser 6 for 80W ultrasonic dispersion for 10 minutes, then left at room temperature for 48 hours, dried in 180°C drying oven 7 for 8 hours, and then placed in a muffle furnace 9 The heating rate of 8°C / min was increased to 450°C for 4 hours, and the obtained sample 8 was passed into H in a high-temperature tube furnace 10 at 600°C. 2 Mixed gas of 11 and Ar 12, H 2 The volume ratio of Ar and Ar is 1:9, after reduction for 3h, 5g of Ni / ZrO with a loading capacity of 10% is obtained 2 catalyst.

Embodiment 3

[0026] Such as figure 1 As shown, 3.891g Ni(NO 3 ) 2 ·6H 2 O 1 was fully dissolved in 8.0ml deionized water 2 to obtain impregnation solution 5; then 4.000g γ-Al 2 o 3 Carrier 4 was added to the above impregnation solution 5, fully shaken for 20 minutes, then placed in ultrasonic disperser 6 for 50W ultrasonic dispersion for 20 minutes, then left at room temperature for 24 hours, dried in 110°C drying oven 7 for 12 hours, and then placed in a muffle furnace 9 was roasted at 500°C at a rate of 5°C / min for 3 hours, and the obtained sample 8 was passed into H2 in a high-temperature tube furnace 10 at 550°C 2 Mixed gas of 11 and Ar 12, H 2 The volume ratio of Ar and Ar is 1:9, and the reduction takes 4 hours to obtain 5 g of Ni / γ-Al with a loading capacity of 20%. 2 o 3 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com