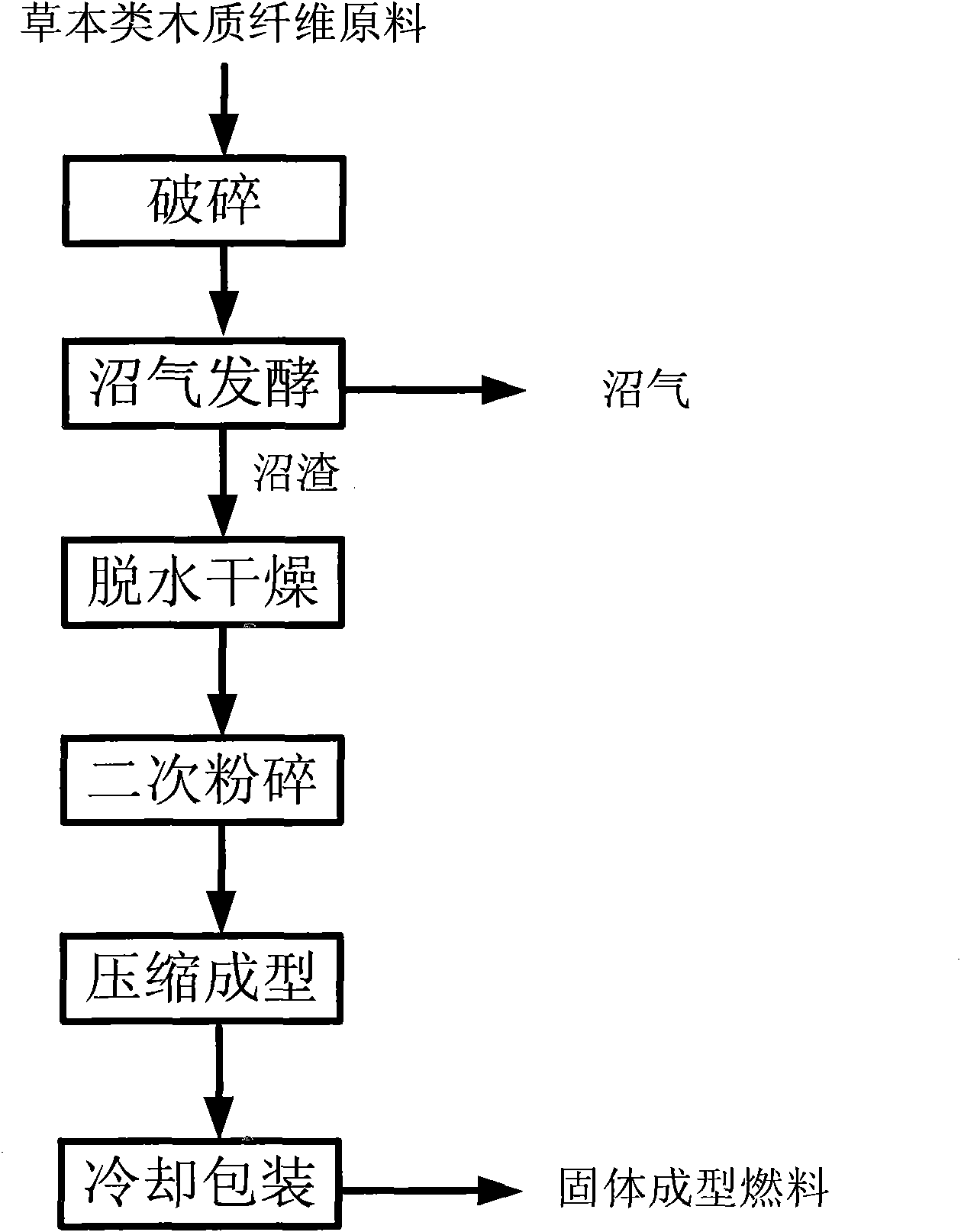

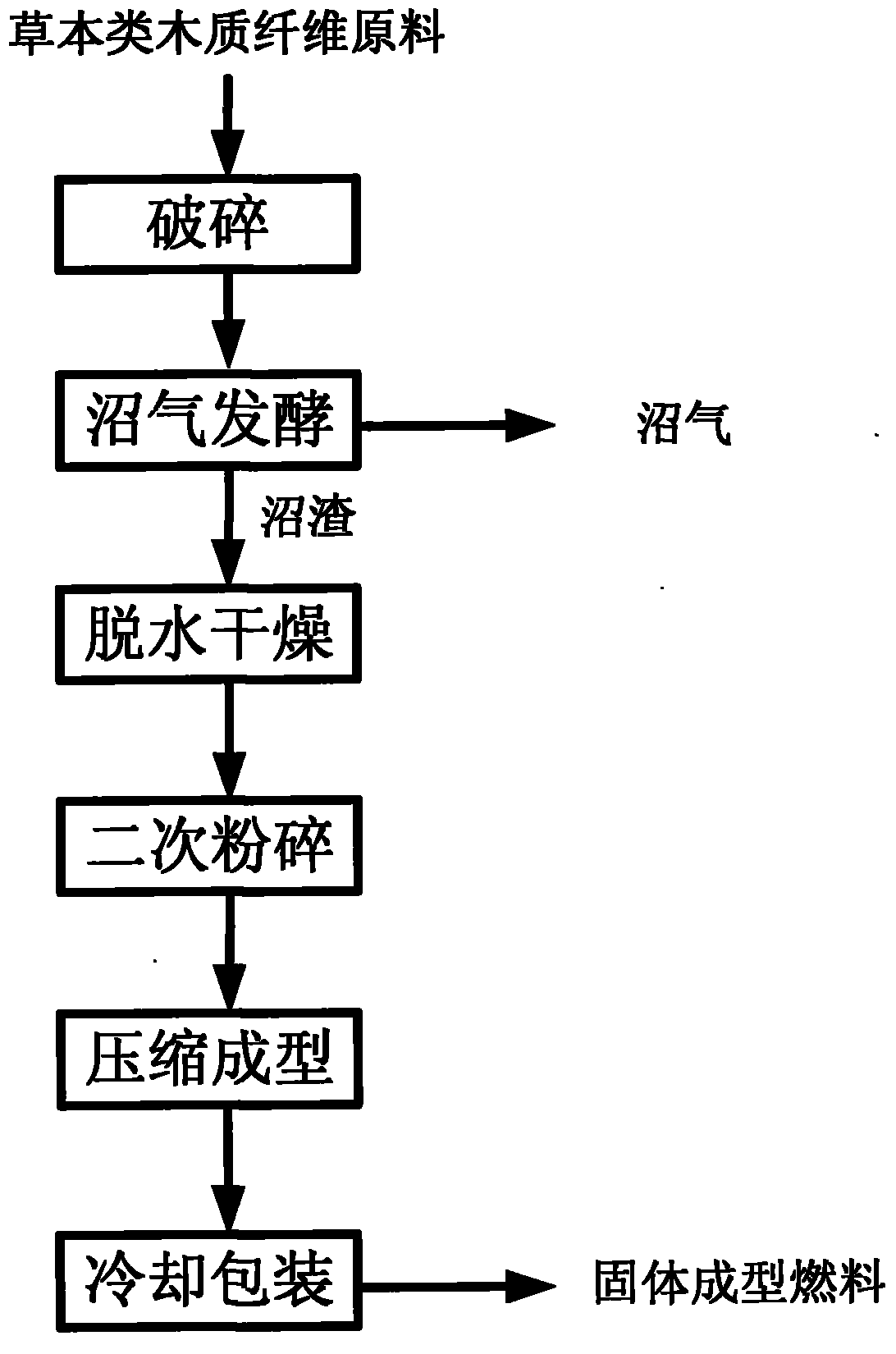

Method for coproducing methane and solid formed fuel by using herbaceous wood fiber as raw material

A technology of lignocellulosic raw material and solid briquette fuel, which is applied in the direction of solid fuel, fuel, biofuel, etc., to achieve the effects of easy crushing, energy utilization, good use performance and storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Using rice straw as herbaceous lignocellulosic raw material, first crush it with a hay cutter to make the particle size less than 40mm; then carry out biogas fermentation, control the solid concentration of biogas fermentation to 40%, the temperature is 55°C, and the fermentation time is 35 days; after the fermentation is completed Finally, take out the biogas residue, and then use a rotary cylinder dryer and a double-drum re-crusher for drying and secondary crushing, so that the moisture content and particle size are controlled at 6% to 12% and below 5mm respectively; finally, screw extrusion is used to The compression molding machine is used for compression molding, and the molding temperature is adjusted at 220 ° C to 280 ° C; after cooling and packaging, the commercialized solid molding fuel can be obtained.

Embodiment 2

[0022] Corn stalks are used as the herbaceous lignocellulosic raw material, first crushed with a hay cutter to make the particle size less than 40mm; then biogas fermentation is carried out, the solid concentration of the biogas fermentation is controlled at 30%, the temperature is 30°C, and the fermentation time is 45 days; to be fermented After the end, the biogas residue is taken out, and the vertical air dryer and the double-drum re-crusher are used for drying and secondary crushing, so that the moisture content and particle size are controlled at 6% to 12% and below 5mm respectively; finally, the screw extrusion is used The compression molding machine is used for compression molding, and the molding temperature is adjusted at 220 ° C to 280 ° C; after cooling and packaging, the commercialized solid molding fuel can be obtained.

Embodiment 3

[0024] Using hybrid pennisetum as herbaceous lignocellulosic raw material, first crush it with a hay cutter to make the particle size less than 40mm; then carry out biogas fermentation, control the solid concentration of biogas fermentation to 20%, the temperature is 38°C, and the fermentation time is 25 days; After the fermentation is over, take out the biogas residue, and then use a vertical air dryer and a double-drum re-crusher for drying and secondary crushing, so that the moisture content and particle size are controlled at 10% to 20% and below 5mm respectively; finally, the piston is used to The extrusion molding machine performs compression molding, and the molding temperature is adjusted at 140°C to 200°C; after cooling and packaging, the commercialized solid molding fuel can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com