Obstacle removing method and obstacle removing device for railway vehicle

A rail vehicle and rail technology, applied in the field of rail vehicle manufacturing, can solve the problems of wear and tear of rubber sheets, reduce friction between wheels and rails, and regularly replace them, so as to ensure safety or reliability, improve wheel-rail friction coefficient, The effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

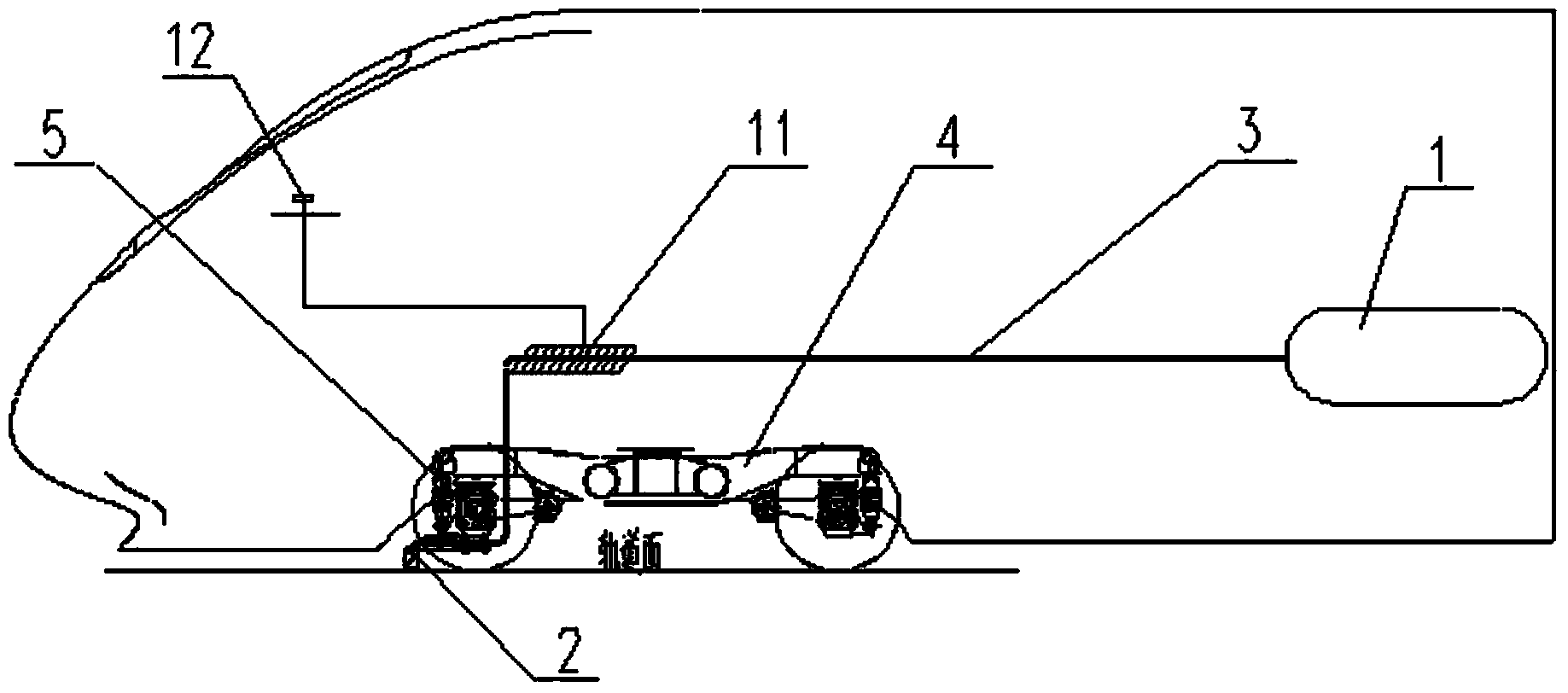

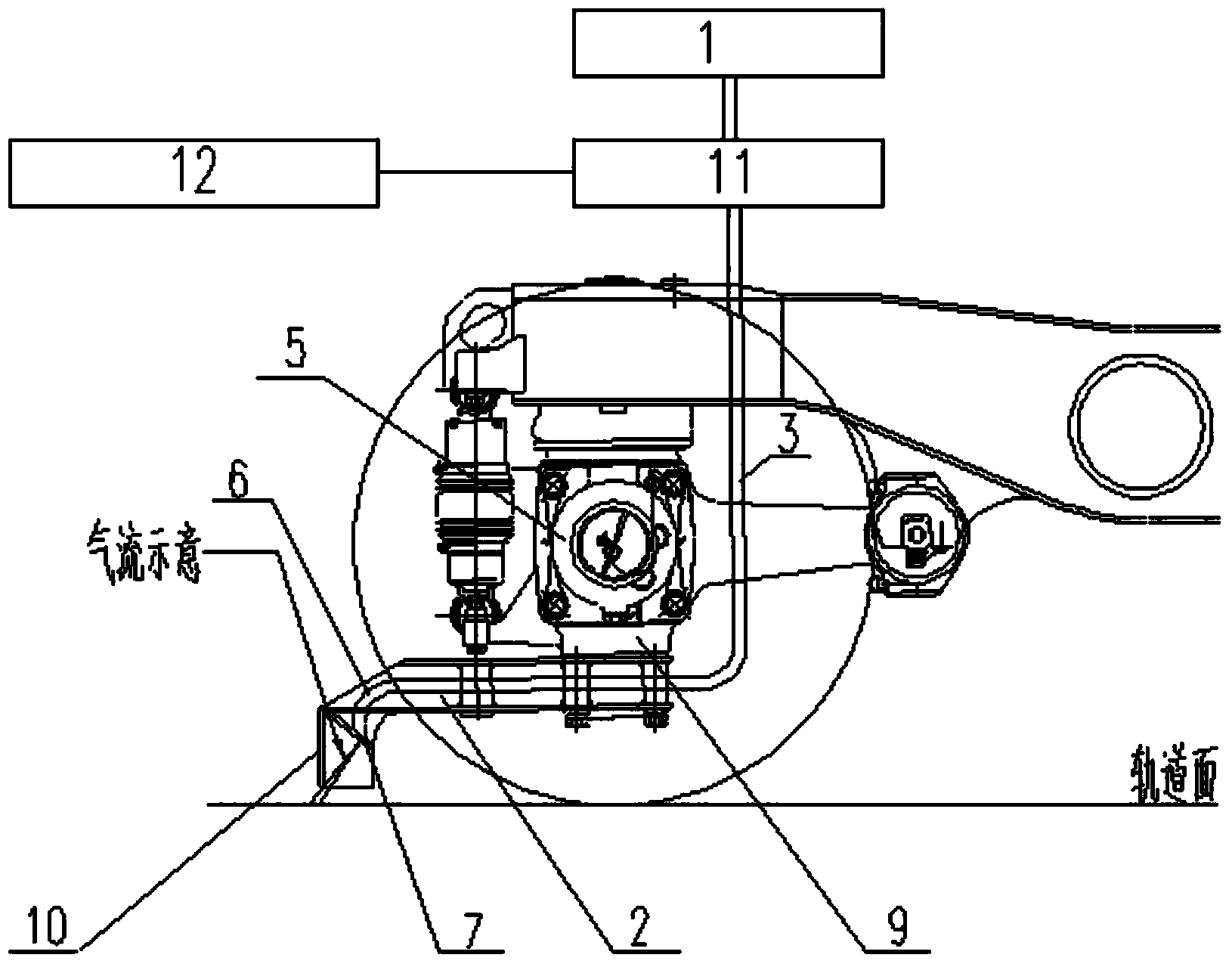

[0034] Such as Figure 1 to Figure 3 As shown, the present invention provides a kind of trouble-shooting method and trouble-shooting device for rail vehicle, and trouble-shooting device comprises air supply air source 1 and injection device 2, and air supply wind source 1 and spray device 2 are connected by air pipe 3 . There are two spraying devices 2, which are respectively connected to the same air supply source 1 through the air pipe 3, or each spraying device 2 is equipped with a supply air source 1.

[0035] In this embodiment, the air supply air source 1 is an air supply air cylinder provided separately for troubleshooting, and the air supply air cylinder is fixedly installed on the vehicle body chassis (not shown in the figure) or on the frame 4 of the bogie. The specifications of the air supply cylinder are determined according to the required air pressure and air volume, generally guaranteed to be 5kg / m 3 The air pressure can meet the needs of troubleshooting. It c...

Embodiment 2

[0049] The difference from Embodiment 1 is that, as Figure 4 As shown, when the axle box body 5 is not suitable for installing the injection device 2, the injection device 2 can be fixedly installed on the frame 4 of the bogie, and a frame mounting seat 13 protrudes downward on the frame 4 in front of the wheel 8, and the injection Spray pipe 6 in the device 2 is installed on the frame mounting seat 13, makes the nozzle mouth of nozzle pipe 6 be positioned at the front of wheel 8, and baffle plate 10 is set in front of the nozzle pipe mouth of nozzle pipe 6.

[0050] In the prior art, due to the action of the spring between the frame 4 and the axle box 5, the height of the obstacle removal device installed on the frame 4 from the rail surface will change continuously. When the obstacle is less than 30mm, the obstacle removal The device will not work at all, but the high-pressure air will not be affected by the up and down movement of the frame 4, and the high-temperature and ...

Embodiment 3

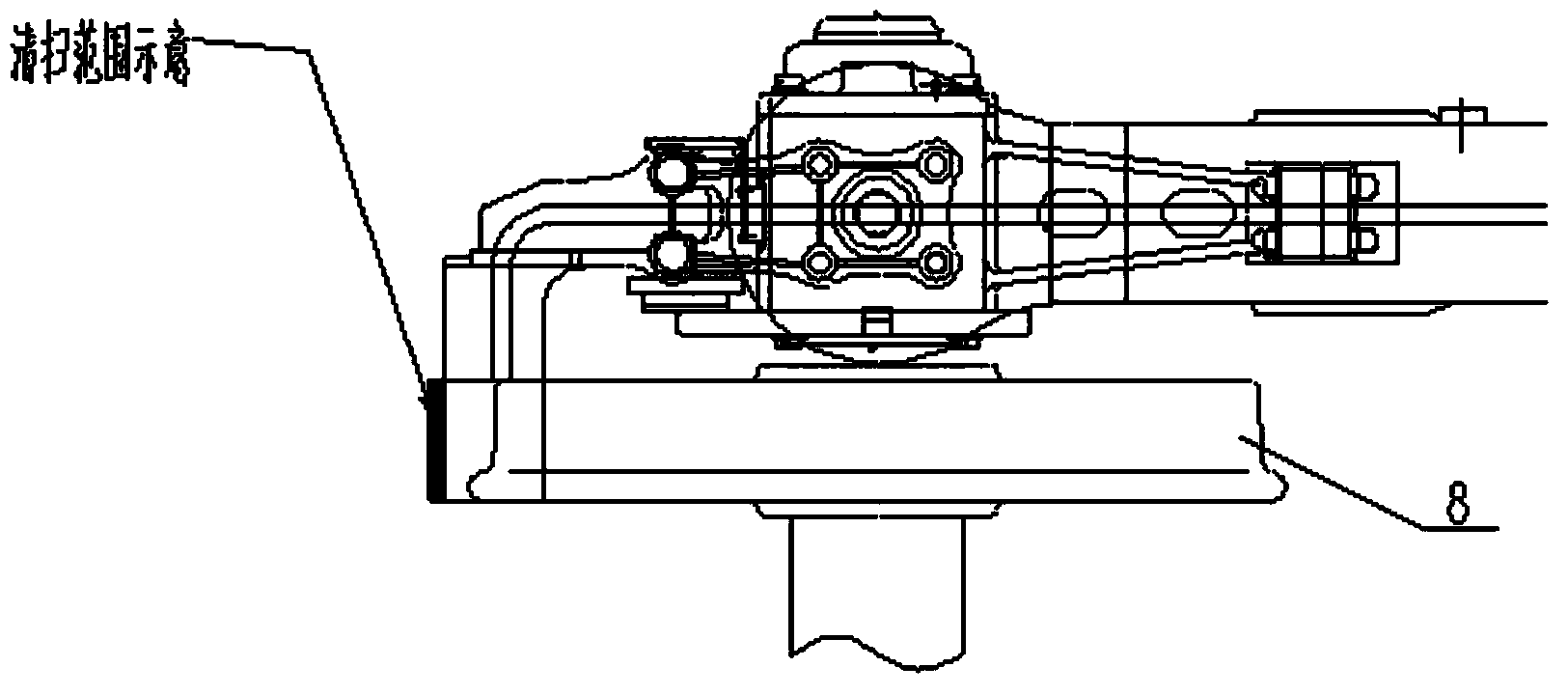

[0052] The difference from the above-mentioned embodiment is that, if Figure 5 As shown, the injection device 2 can also be fixed on the underframe of the car body, installed on the front end of the underframe of the car body, and protrude a mounting seat (not shown in the figure) downwards on the underframe in front of the wheel 8, spraying Spray pipe 6 among the device 2 is installed on the mounting seat, makes the nozzle mouth of nozzle pipe 6 be positioned at the front of wheel 8, and baffle plate 10 is set in front of the nozzle pipe mouth of nozzle pipe 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com