High-impact-toughness steel rail and production method thereof

A production method and high-impact technology, applied in furnace types, quenching agents, heat treatment furnaces, etc., can solve problems such as high impact toughness, and achieve good strength and toughness matching, rolling contact fatigue performance and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

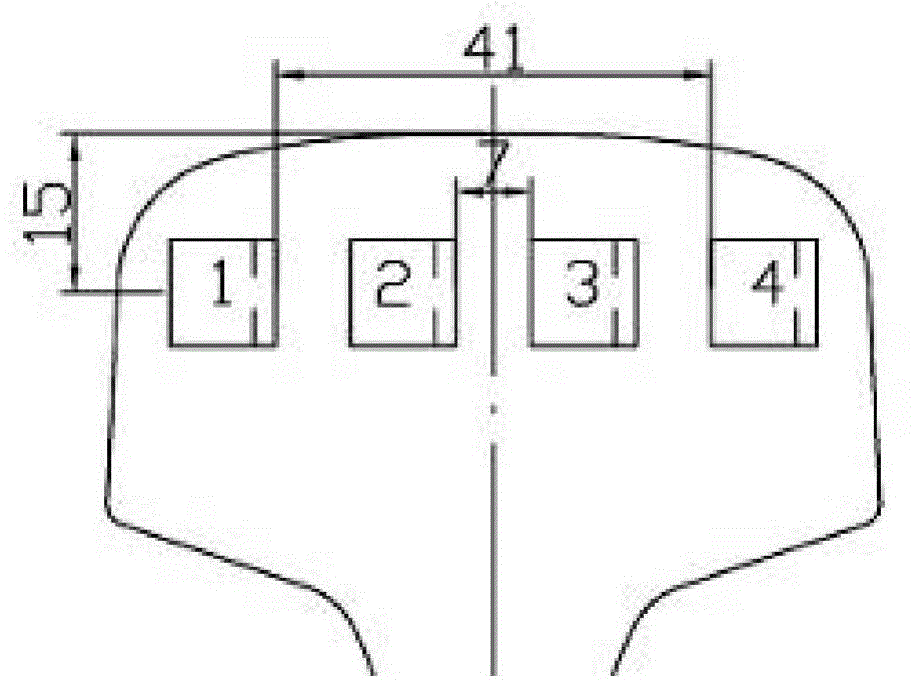

Image

Examples

Embodiment 1

[0033] The chemical composition of the rail is C: 0.72%, Si: 0.35%, Mn: 0.98%, V: 0.05%, Al: 0.04%, P: 0.011%, S: 0.006% by weight, the balance is Fe and unavoidable 的impurities.

[0034] Use low-sulfur molten iron into the furnace, smelt pearlitic rail steel through a converter or electric furnace, use high-basicity refining slag for full protection and pouring, use anthracite and low-nitrogen alloys as recarburizers, use foaming agents and RH during refining in LF furnaces Or, after VD vacuum treatment, continuous casting into a steel billet with a certain section size is sent to a heating furnace for heating. Generally, the tapping temperature in the heating furnace is 1000°C; the steel billet is dephosphorized by multiple points of high-pressure water and rolled by a universal rolling mill.

[0035] After the rolling is completed, the waste heat of the steel rail is used to spray accelerated cooling medium to the center of the rail head tread, the two sides of the rail head and...

Embodiment 2~ Embodiment 5

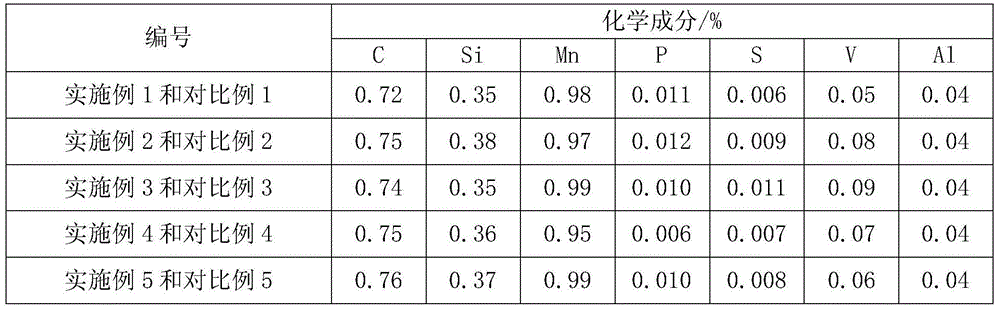

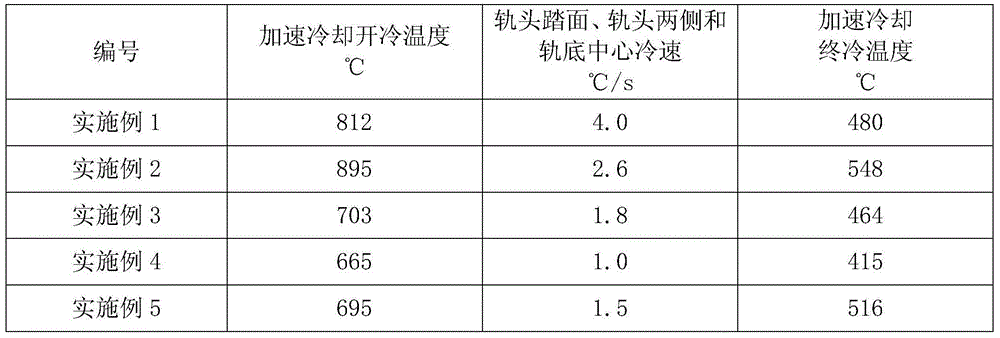

[0039] The chemical composition and heat treatment process parameters of the steel rail in Example 1 were changed, and Example 2 to Example 5 were performed. Table 1 lists the chemical composition of the steel rails of Examples 1 to 5, Table 2 lists the heat treatment process parameters of Examples 1 to 5 (including accelerated cooling opening temperature, cooling rate and final cooling temperature), and Table 3 lists The tensile properties and metallographic structure of Examples 1 to 5 are listed. Table 4 lists the impact properties of Examples 1 to 6 at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com