Lever power-driven loading type rolling contact fatigue test machine

A rolling contact fatigue and testing machine technology, applied in the direction of mechanical devices, mechanical bearing testing, measuring devices, etc., can solve the problems of affecting economic benefits, large power consumption, and high cost, so as to improve economic benefits, save electric energy, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

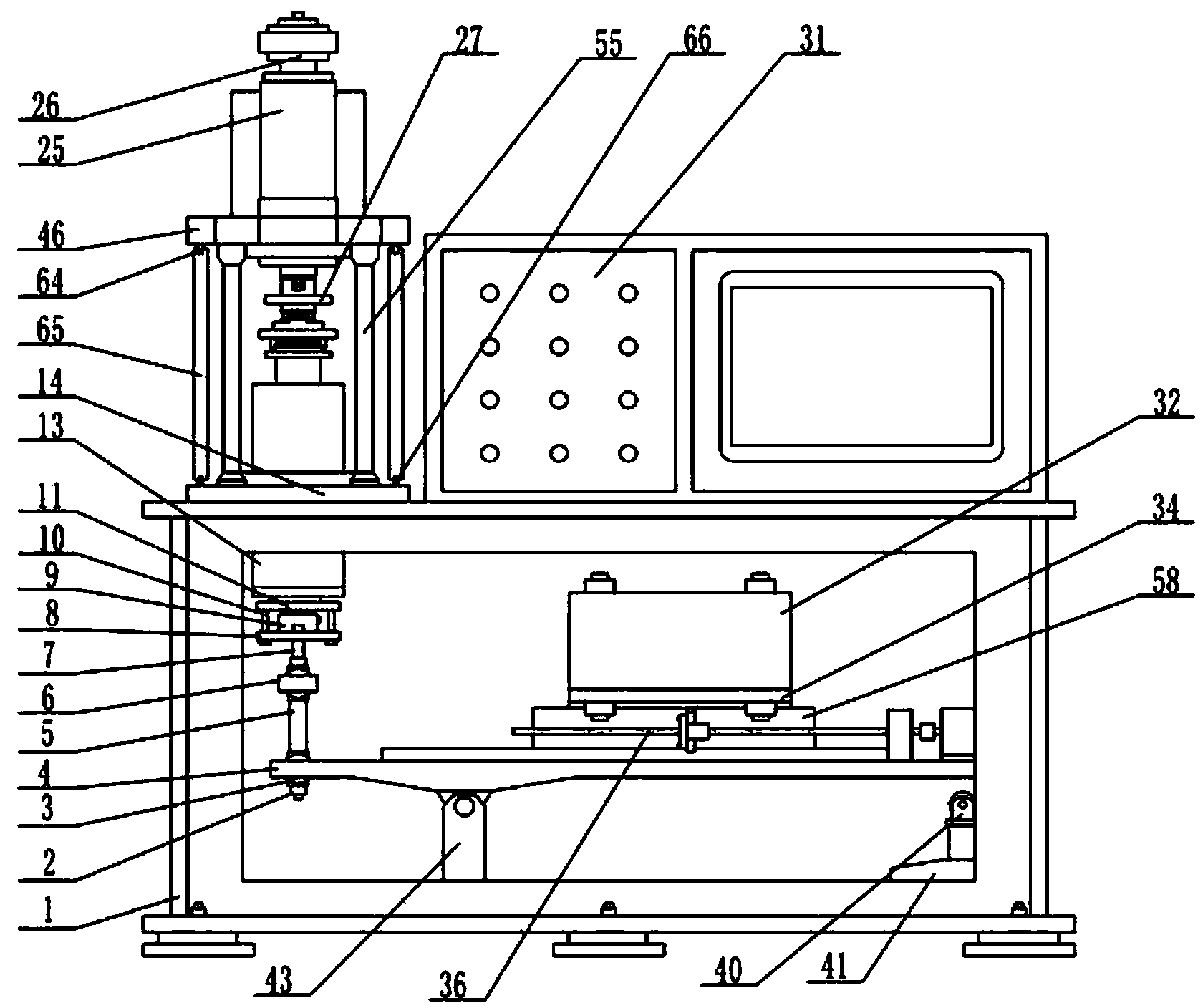

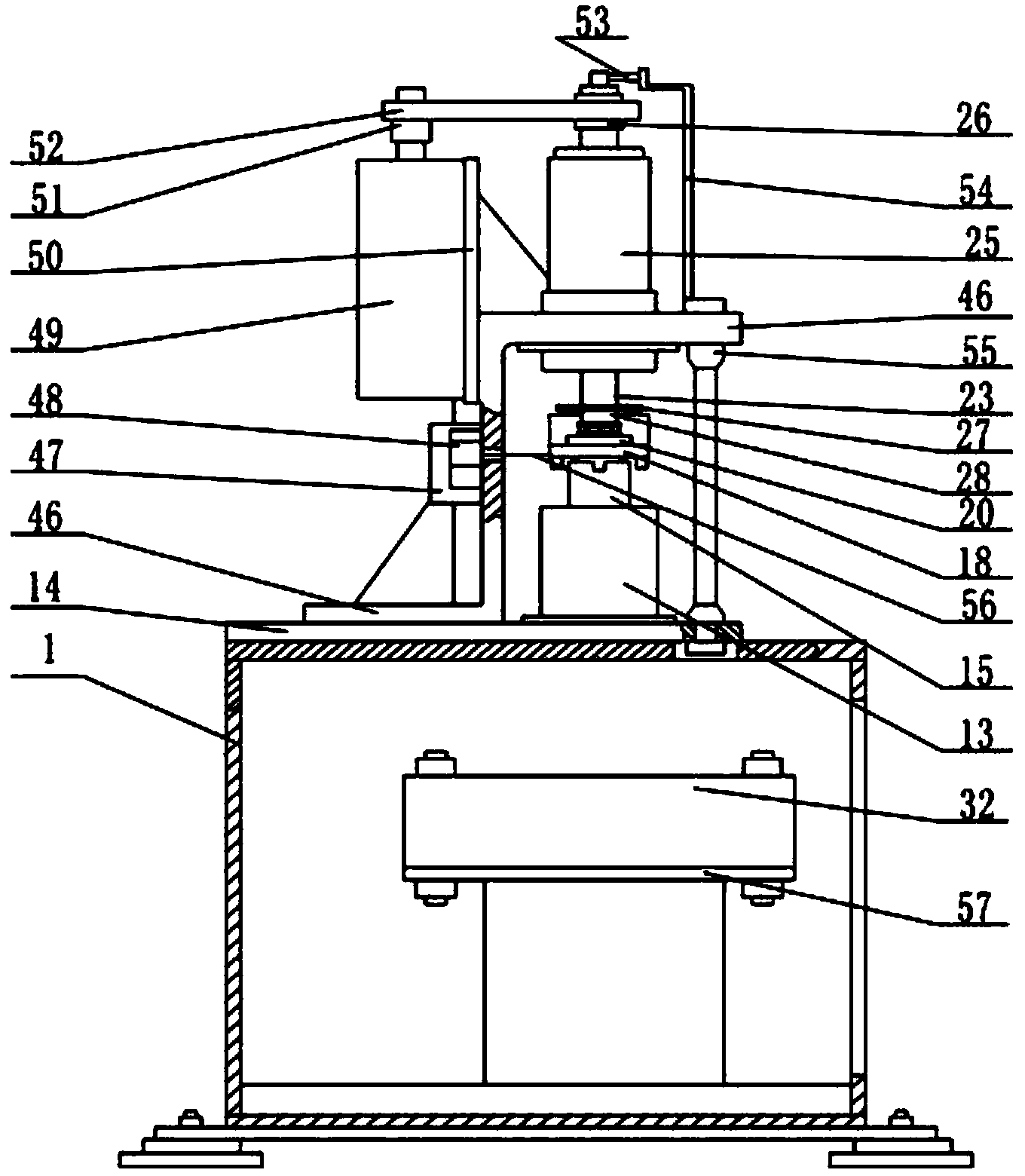

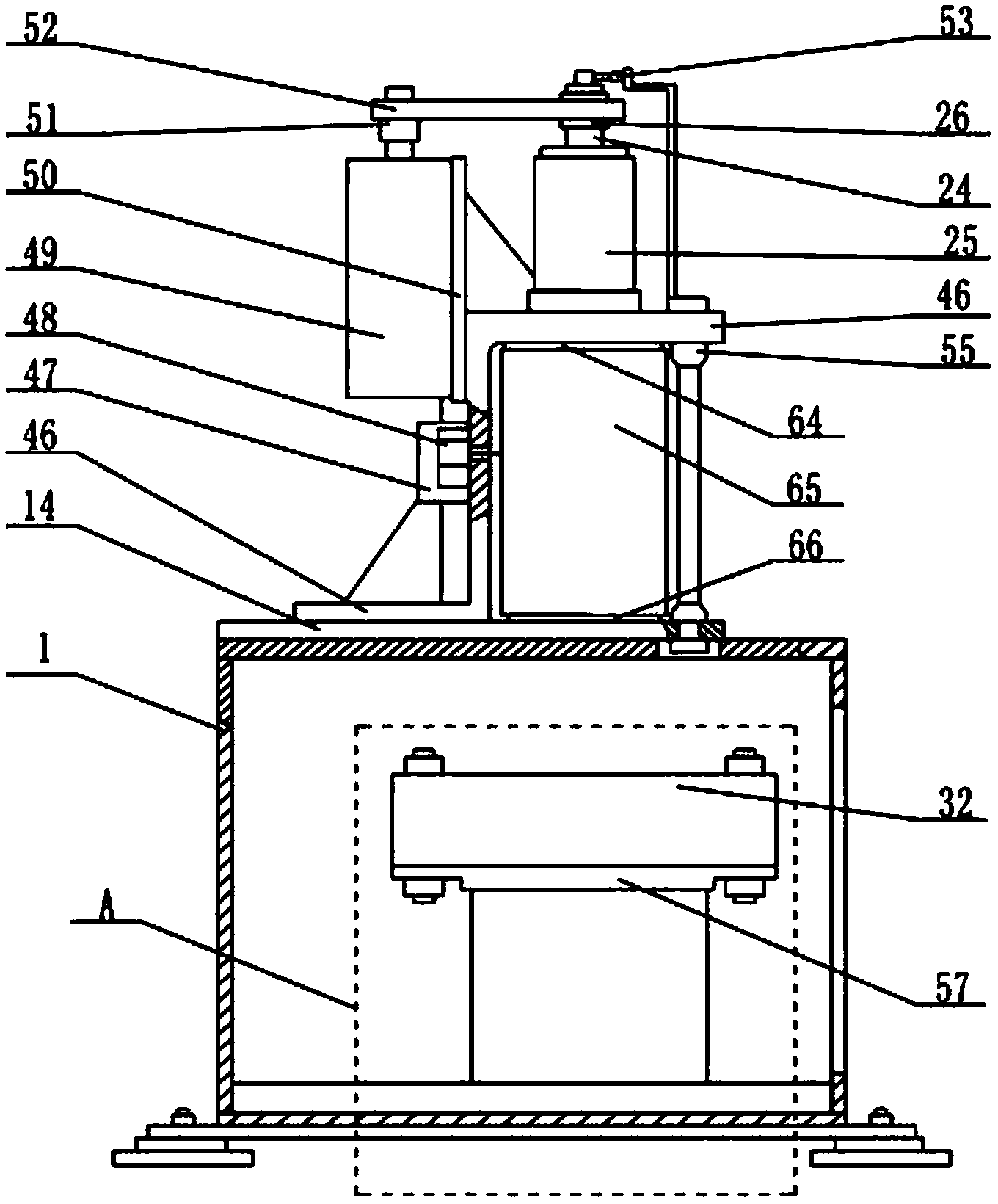

[0025] figure 1 , figure 2 and image 3 It is a structural schematic diagram of a lever electric loading type rolling contact fatigue testing machine disclosed by the present invention. Depend on Figure 1 to Figure 9 It can be seen that the support plate 14 and the control cabinet 31 are fixed on the base 1, the headstock installation frame 46 is fixedly installed on the support plate 14, two columns 55 are fixedly arranged between the headstock installation frame 46 and the support plate 14, and the headstock installation frame 46 The motor bracket 50 is fixedly installed on the cantilever beam of the motor.

[0026] The high-speed main shaft motor 49 is fixed on the side of the motor support 50, and the driving pulley 51 is fixedly installed on the output shaft of the high-speed main shaft motor 49. Pulley 26 transmission connection; main shaft 24 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com