Bearing steel and ingot material for bearing having excellent rolling contact fatigue life characteristics and method for manufacturing the same

A manufacturing method and technology of bearing steel, applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of reduced yield, large economic burden, and large dimensional changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

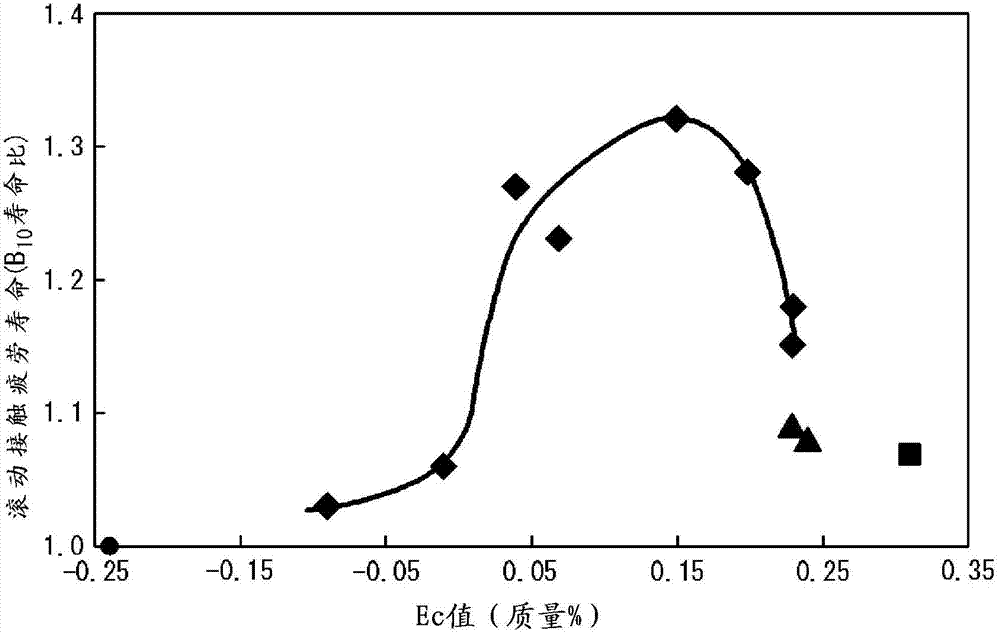

Embodiment 1

[0168] The steel having the composition shown in Table 5 was smelted in a converter, and then cast slabs with the dimensions shown in Table 6 were produced by ingot casting or continuous casting, forged and heated under the conditions shown in Table 6, and one side was produced. A steel sheet with a square section with a length of 650 mm. The presence or absence of eutectic carbides, the degree of segregation, rolling contact fatigue life characteristics, and machinability of the forged product were investigated as follows.

[0169] Steel No.

C

Si

mn

P

S

Cr

Al

Mo

O

N

Ec

Remark

A-1

1.05

0.25

0.45

0.016

0.008

1.45

0.025

0.07

0.0010

0.0031

-0.24

benchmark steel

C-1

0.64

0.25

0.83

0.011

0.006

0.79

0.026

0.25

0.0010

0.0031

0.13

invention steel

C-2

0.60

0.31

0.81

0.009

0.004

0.77

0.02...

Embodiment 2

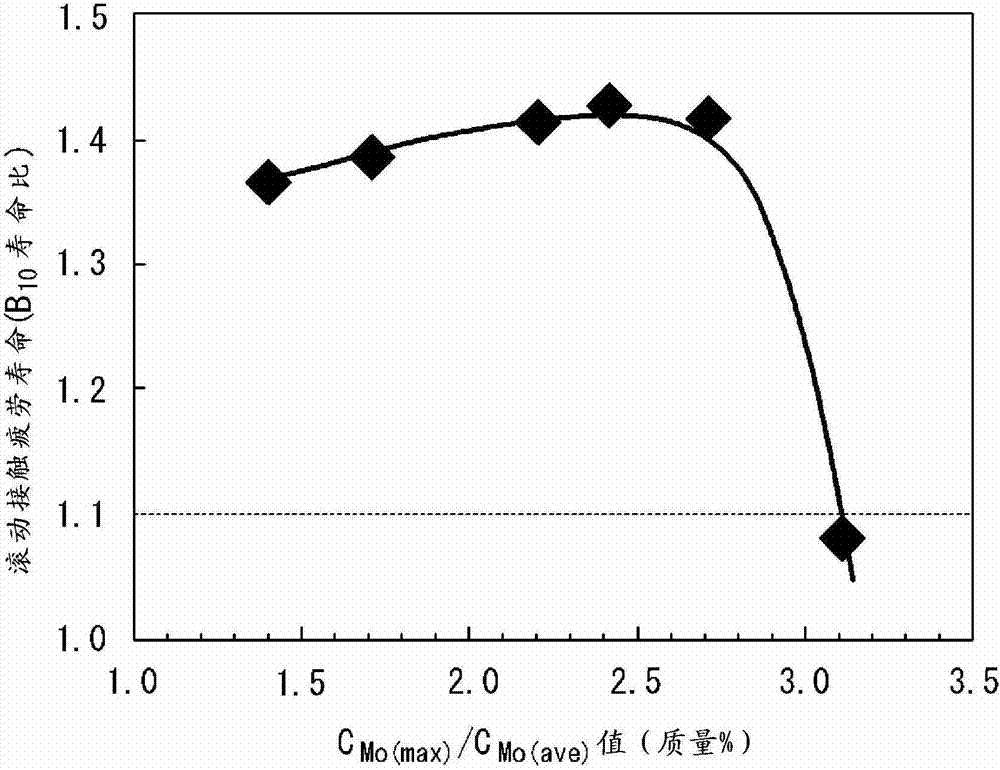

[0185] The steel having the composition shown in Table 8 was smelted in a converter, and then made into a steel ingot by the ingot casting method, and the steel ingot was made into an ingot under the conditions shown in Table 9, and the obtained ingot was heated to 1270°C After holding for 15 hours, forging is carried out to produce a steel sheet with a square section with a length of 450-750 mm on one side, or a steel sheet with a circular section with a diameter of 450-800 mm. Next, a heat treatment in which the forged steel sheet was heated to 1270° C. and held for 20 hours was implemented.

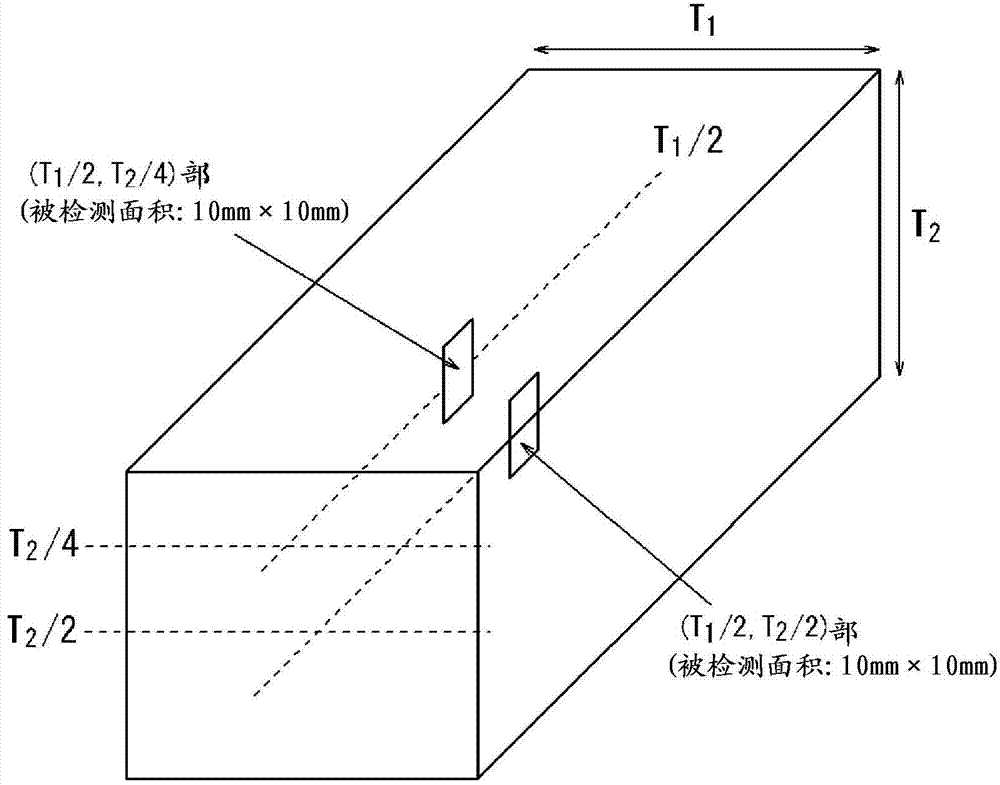

[0186] The presence or absence of eutectic carbides, the degree of segregation, rolling contact fatigue life characteristics, and machinability of the forged product were investigated in the same manner as in Example 1 above. It should be noted that for the sampling position of the test piece, the steel piece with a square cross-section is the same as that of the above-mentioned Exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com