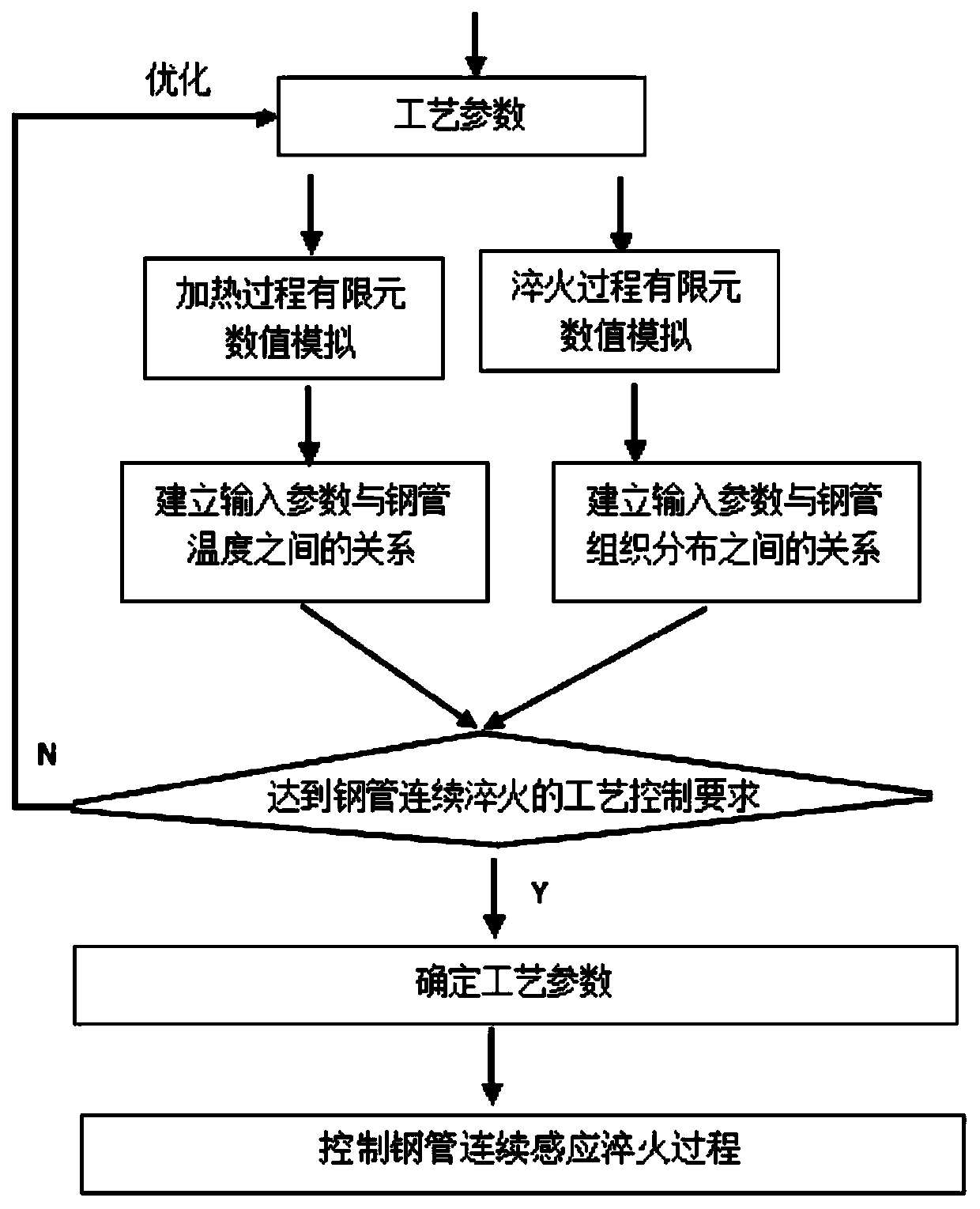

Steel pipe continuous quenching process control method based on numerical simulation

A technology of process control and numerical simulation, applied in heat treatment process control, quenching equipment, manufacturing tools, etc., can solve problems such as cracking, quenching soft spots, insufficient hardness, and limited application range, so as to reduce the temperature difference of steel pipes, reduce energy consumption, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

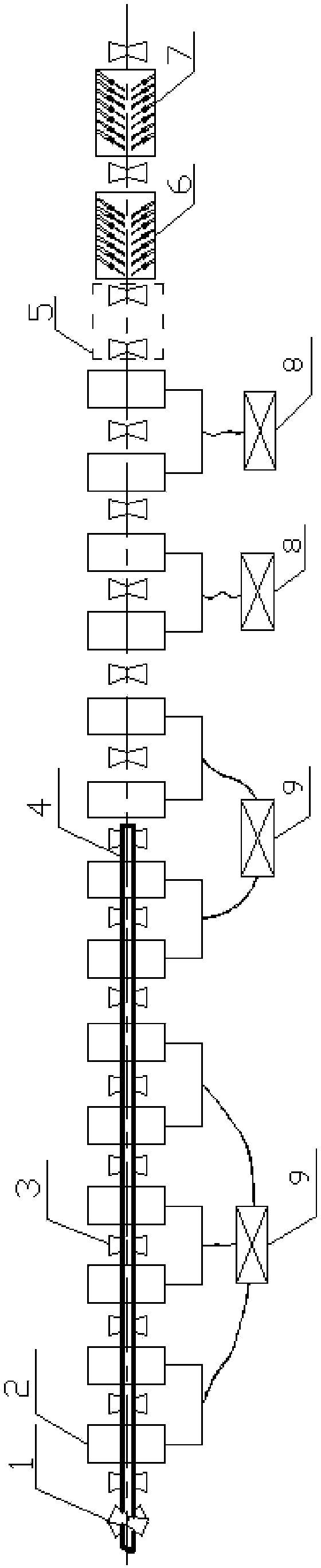

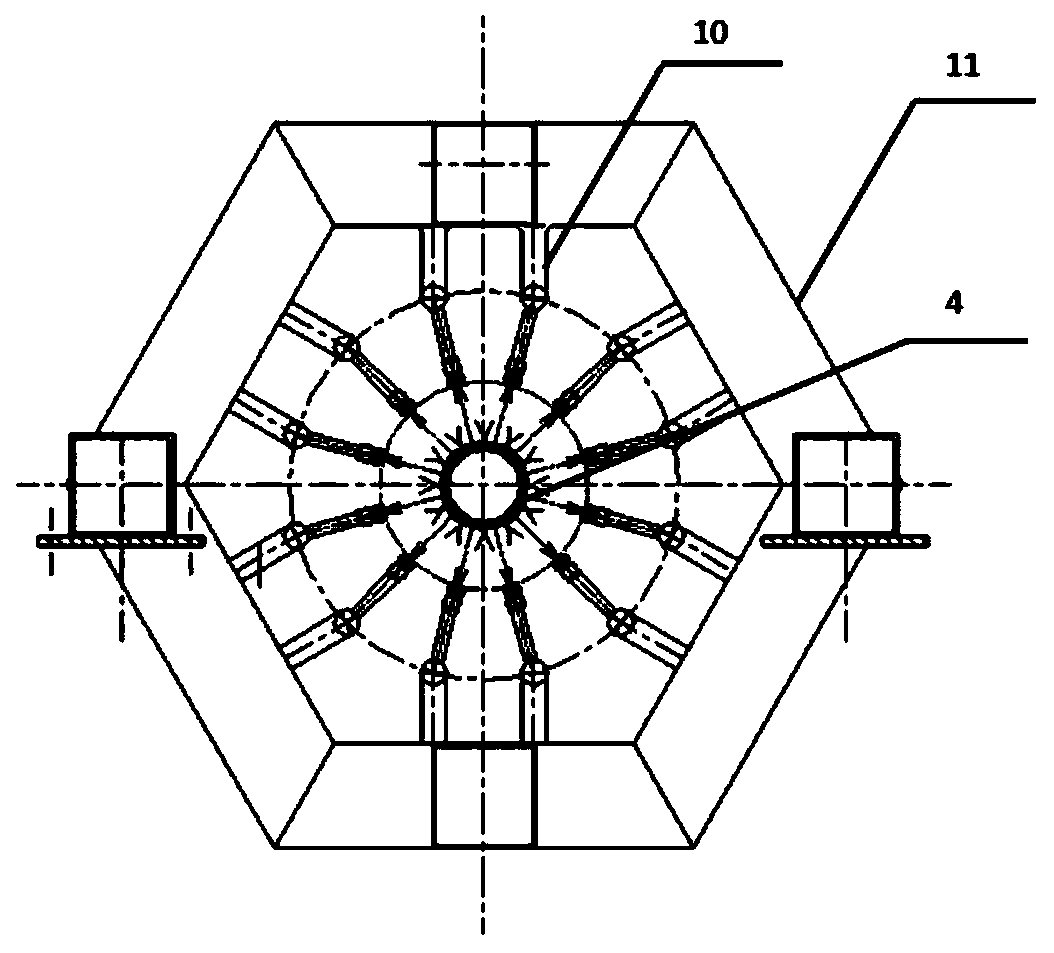

[0059] Such as figure 1 and figure 2 As shown, the steel pipe continuous induction quenching complete set used in the embodiment of the present invention includes a front straightening tractor 1, an induction heater group 2 and a spray quenching cooling chamber connected in sequence. The induction heater group 2 is 14 groups of mutually independent induction heating furnaces, the first 10 groups are low-frequency heating sections, controlled by two low-frequency power supply control cabinets 9; the last 4 groups are medium-frequency heating sections, controlled by two medium-frequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com